Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

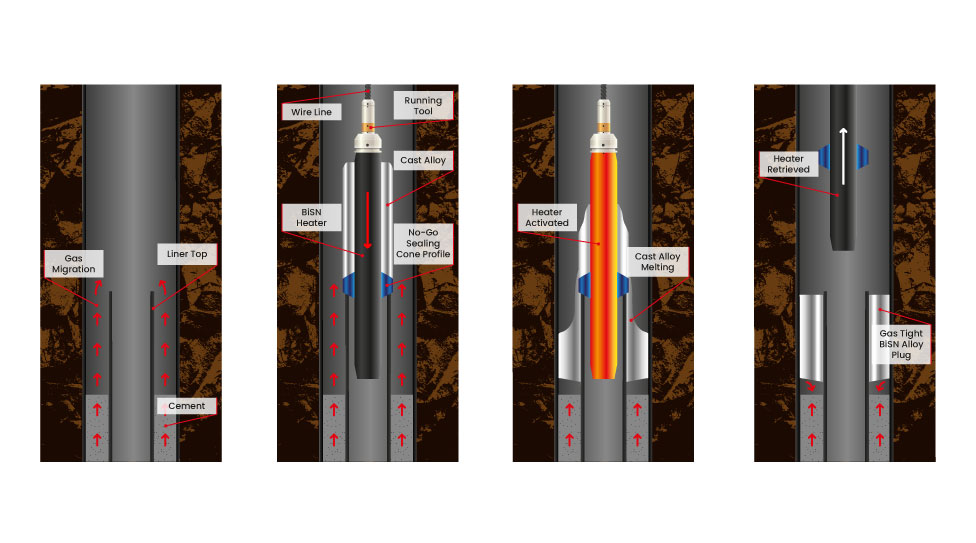

Leaking liner tops, a common and ongoing problem in the oil field, can not only lead to gas or fluid migration from non-productive zones during the lifecycle of the well, but can also result in lower than desired frack pressures if the leak is substantial. Cementing liners has been notoriously difficult and has resulted in a very high number of leaking liner tops.

BiSN’s Wel-lok™ Liner Top Repair (LTR) tool has been specifically designed to seal off leaking cemented liner tops. In a single trip, the LTR melts bismuth-based alloys and directs the liquid alloy into the annular gap between the liner and the casing at the very top to create a gas-tight seal.

The LTR tool is a faster, simpler, and longer lasting alternative to the current solution of squeezing cement, which can be time consuming and often fails to provide a gas-tight seal.

The tool can be run on wireline, coiled tubing and drill pipe. Once heated, the alloy flows under gravity like water, creating a gas-tight seal.

The LTR has been developed and qualified to downhole conditions, successfully sealing off leaking liner tops with the ability to withstand fracking pressures up to 13,000 PSI.

Download Spec Sheet

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies