Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Following up with Aker BP after 2 years of monitoring and testing

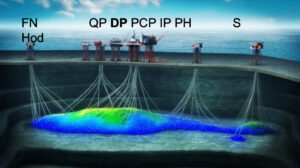

Aker BP, a major global operator, needed to safely plug and abandon 30 wells in the Valhall field in the North Sea. BiSN partnered with Aker BP to deploy Wel-lok™ technology to create safe and cost-efficient Wel-lok™ plugs. This not only allowed for a permanent plug and abandonment solution, but also allowed for new wells to be drilled and operated safely for the next 30 years.

After two years BiSN caught up with representatives from Aker BP to discuss the success of the campaign.

Representatives from Aker BP had the opportunity to reflect on the 2020, 30 well P&A campaign.

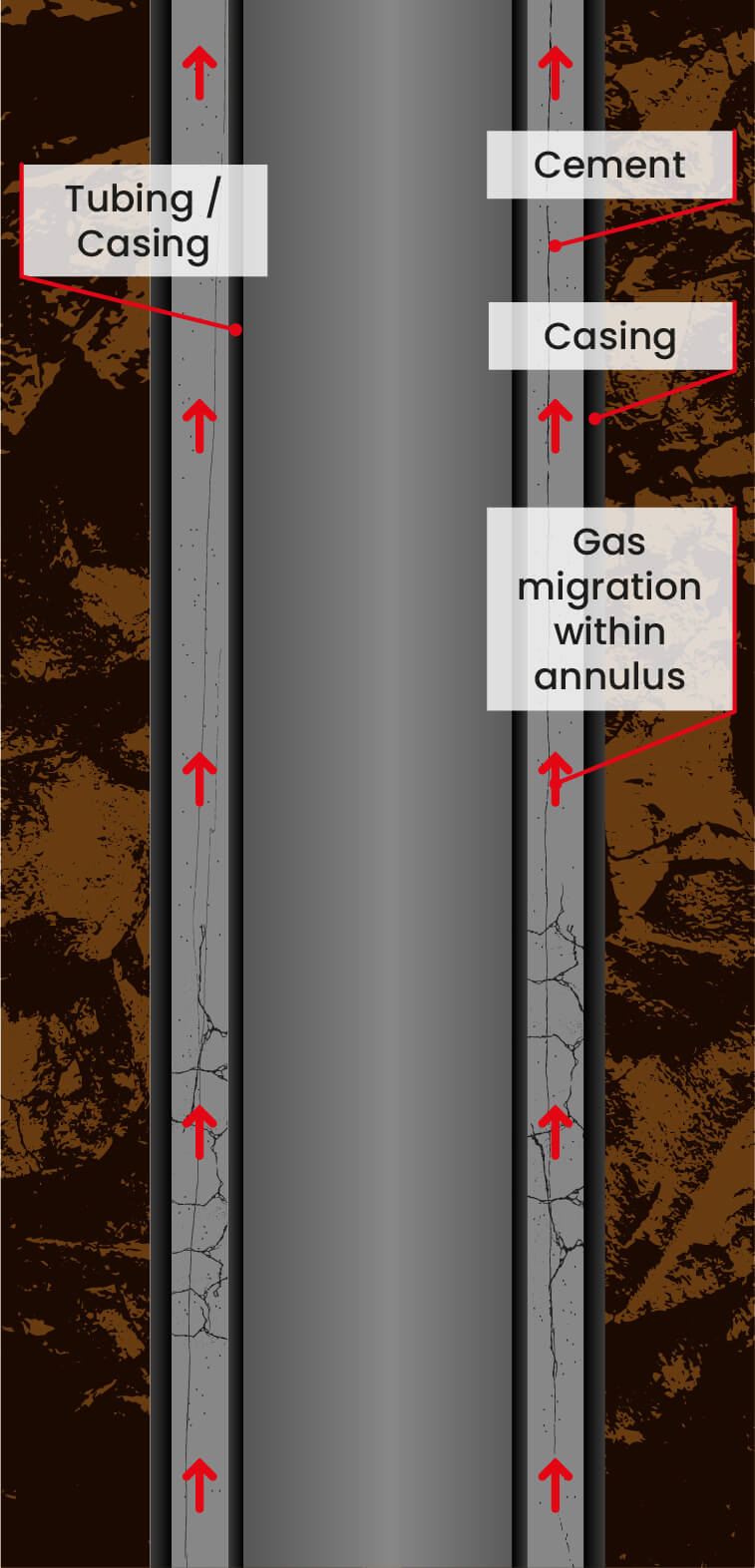

Multiple wells in the Valhall field were experiencing annulus pressure which increased the possibility of gas migration to the surface in the future.

The Valhall field is located in the southern sector of the Norwegian North Sea.

For two years prior to the beginning of the campaign in 2020, Aker BP and BiSN carried out a joint testing program to ensure Wel-lok™ technology was the safest and cost-effective option at BiSN’s Houston location.

In order for the test to be successful, the following requirements were needed:

Watch the documentary of BiSN in Houston carrying out the qualification testing with Aker BP.

As a result of the rigorous testing done at BiSN’s Houston facility on behalf of Aker BP, BiSN Wel-lok™ technology received acknowledgement of consent for use including DNV-GL verification and PSA (NORSOK) evaluation of bismuth.

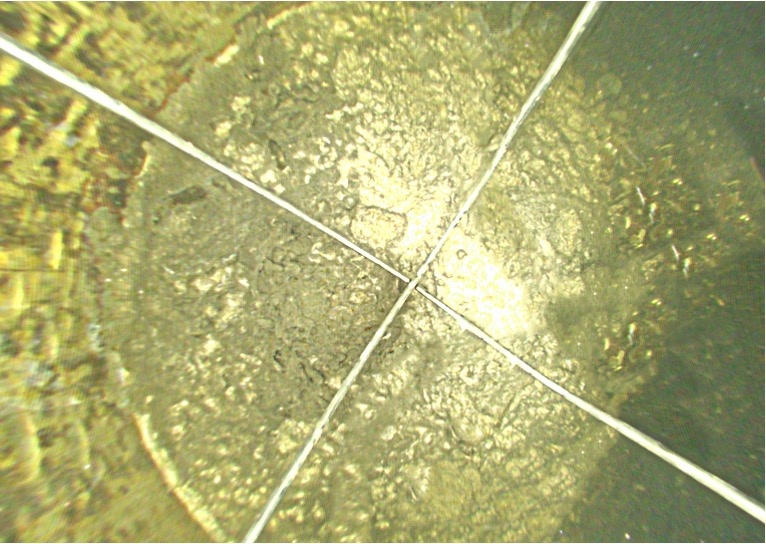

24 months prior to the main campaign one well was chosen for a long term field test. A known gas generating zone was perforated below where the BiSN plug was set. After setting the well was continuously monitored for 24 months. At the beginning of the main campaign the plug was milled out and a large gas show was seen providing the final confirmation a gas tight seal had been created for the 24 month test duration.

The actual bismuth plug from the test well.

BiSN provided the customer with a reliable solution for permanent abandonment.

This eliminated the risk of an ineffective cement squeeze while providing the long-term reliability of Wel-lok™ alloy. As bismuth-based alloy can form an effective seal with a shorter plug length, the need to section mill a long window for a replacement cement plug represented significant cost savings for the operator. BiSN was able to help the operator reduce HSE risks, operation time, and cost.

The Valhall field in the Norwegian North Sea.

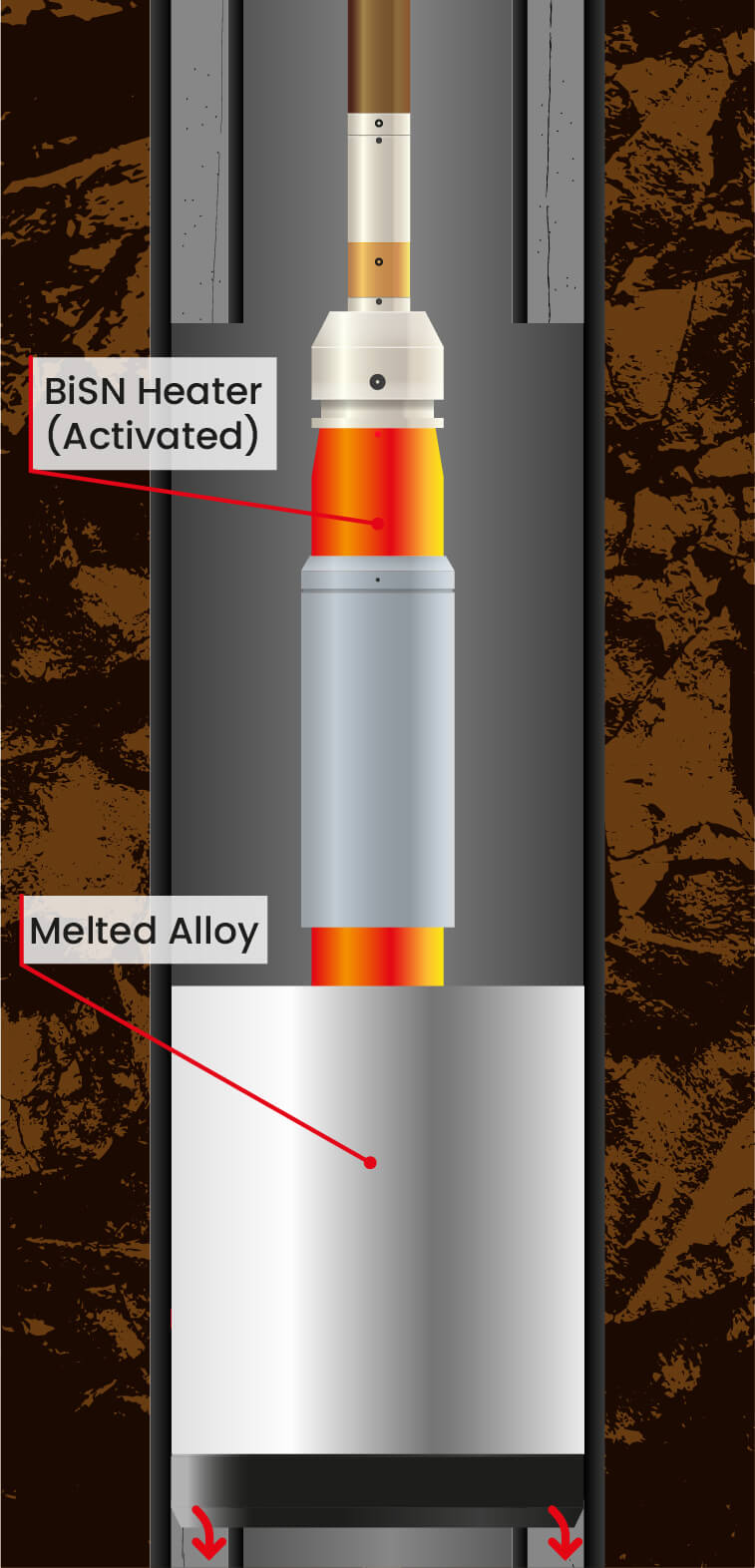

As part of the campaign, BiSN delivered the largest bismuth plug to ever be deployed to date. The tool was produced in BiSN’s UK facility.

Total weight: 33,191 lbs

Alloy weight: 20,366 lbs

Thermite: 2,778 lbs

The largest bismuth plug in the world at the time of deployment.

The following digram demonstrates the fluctuation in annulus pressure during the well history since 2014. The final column demonstrates the effectiveness in BiSN’s Wel-lok™ technology after the bismuth plug had been placed in each well.

| DA Pmax 0 bar |

| DA Pmax < 0.5 bar |

| DA Pmax > 0.5 bar |

| DA Pmax > 5 bar |

| Well | 2014 | 2016 | 2017 | 2018 | 2019 | 2020 |

| A1 | ||||||

| A2 | ||||||

| A3 | ||||||

| A4 | ||||||

| A5 | ||||||

| A6 | ||||||

| A7 | ||||||

| A8 | ||||||

| A9 | ||||||

| A10 | ||||||

| A11 | ||||||

| A12 | ||||||

| A13 | ||||||

| A14 | ||||||

| A15 | ||||||

| A16 | ||||||

| A17 | ||||||

| A18 | ||||||

| A19 | ||||||

| A20 | ||||||

| A21 | ||||||

| A22 | ||||||

| A23 | ||||||

| A24 | ||||||

| A25 | ||||||

| A26 | ||||||

| A27 | ||||||

| A28 | ||||||

| A29 | ||||||

| A30 |

| Well | 2014 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 – BiSN Plug |

| A1 | |||||||

| A2 | |||||||

| A3 | |||||||

| A4 | |||||||

| A5 | |||||||

| A6 | |||||||

| A7 | |||||||

| A8 | |||||||

| A9 | |||||||

| A10 | |||||||

| A11 | |||||||

| A12 | |||||||

| A13 | |||||||

| A14 | |||||||

| A15 | |||||||

| A16 | |||||||

| A17 | |||||||

| A18 | |||||||

| A19 | |||||||

| A20 | |||||||

| A21 | |||||||

| A22 | |||||||

| A23 | |||||||

| A24 | |||||||

| A25 | |||||||

| A26 | |||||||

| A27 | |||||||

| A28 | |||||||

| A29 | |||||||

| A30 |

| BiSN Plug | 2021 |

| A1 | |

| A2 | |

| A3 | |

| A4 | |

| A5 | |

| A6 | |

| A7 | |

| A8 | |

| A9 | |

| A10 | |

| A11 | |

| A12 | |

| A13 | |

| A14 | |

| A15 | |

| A16 | |

| A17 | |

| A18 | |

| A19 | |

| A20 | |

| A21 | |

| A22 | |

| A23 | |

| A24 | |

| A25 | |

| A26 | |

| A27 | |

| A28 | |

| A29 | |

| A30 |

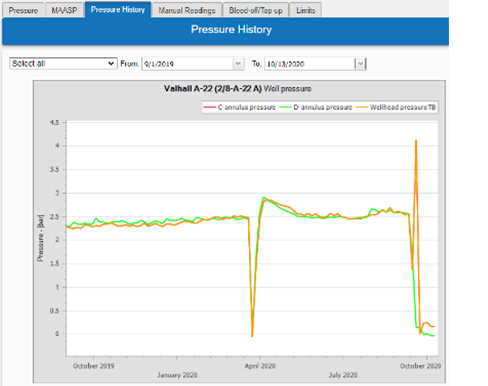

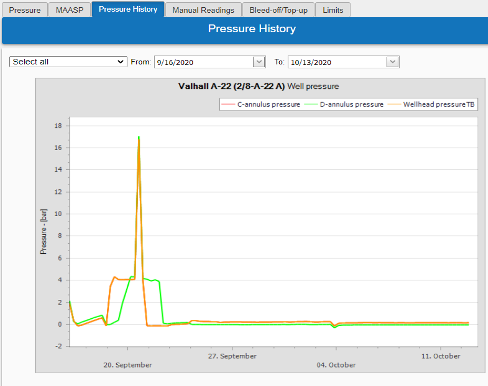

For well A-22, the difference in annulus pressure before and after setting a Wel-lok™ technology plug is evident. Since 2014, the well had experienced annulus pressure of DA Pmax of greater than 0.5 BAR. After the BiSN Wel-lok™ technology plug was set, that pressure dropped to 0 BAR immediately and was sustained over the next 24 month testing period.

Before BiSN campaign with Aker BP.

After deployment of BiSN Wel-lok™ technology.

This table demonstrates the cost effectiveness of using Wel-lok™ plugs in terms of rig time for one individual well. For Wel-lok™ technology, the total time is only 1.7 days compared to cement’s 4.6 days.

When spread out over the course of a 30 well campaign, the total savings add up to 3 months of rig time, or approximately $2mm/well.

| Rig Time (hrs) | ||

| Bismuth | Cement | |

| Dress of cement plug | 6.1 | 6.1 |

| Starter cut / Initiate window | 6.7 | 6.7 |

| Section mill window | 10.1 | 75.75 |

| Scrub window | 4.7 | 10 |

| Cleaning BOP / cleanout run | 1.9 | 4 |

| Install and verify foundation | 4.6 | 5 |

| Place Wel-lok™ plug | 6.8 | – |

| Place cement plug | – | 4 |

| Wait on bismuth and verify | offline | – |

| Wait on cement and verify | – | offline |

| Total (hrs) | 40.9 | 111.55 |

The Wel-lok™ STC (Seal Through Casing) has been developed to achieve a gas tight V0 seal well annuli that cannot be achieved by traditional cement balance plugs. Run on electric line, this tool does not need surface pumping equipment to circulate the alloy in place. Due to its viscosity and density, once melted the liquid alloy will flow with gravity into the annulus. When it cools below its melting point it solidifies, expands and creates a gas tight seal across the entire wellbore. The entire process, from melting to solidification, takes place in minutes and the seal is ready to test within an hour.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies