Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

BiSN collaborated with Sasol in Mozambique to prove the effectiveness of Wel-lok™ technology.

BiSN collaborated with the major operator Sasol in Mozambique to successfully qualify the Wel-lok™ CRT tool to begin the partnership ahead of a campaign in the country. As part of the first run BiSN and Sasol logged the resulting plug via a cement logging tool to prove the effectiveness of a Wel-lok™ seal with great success.

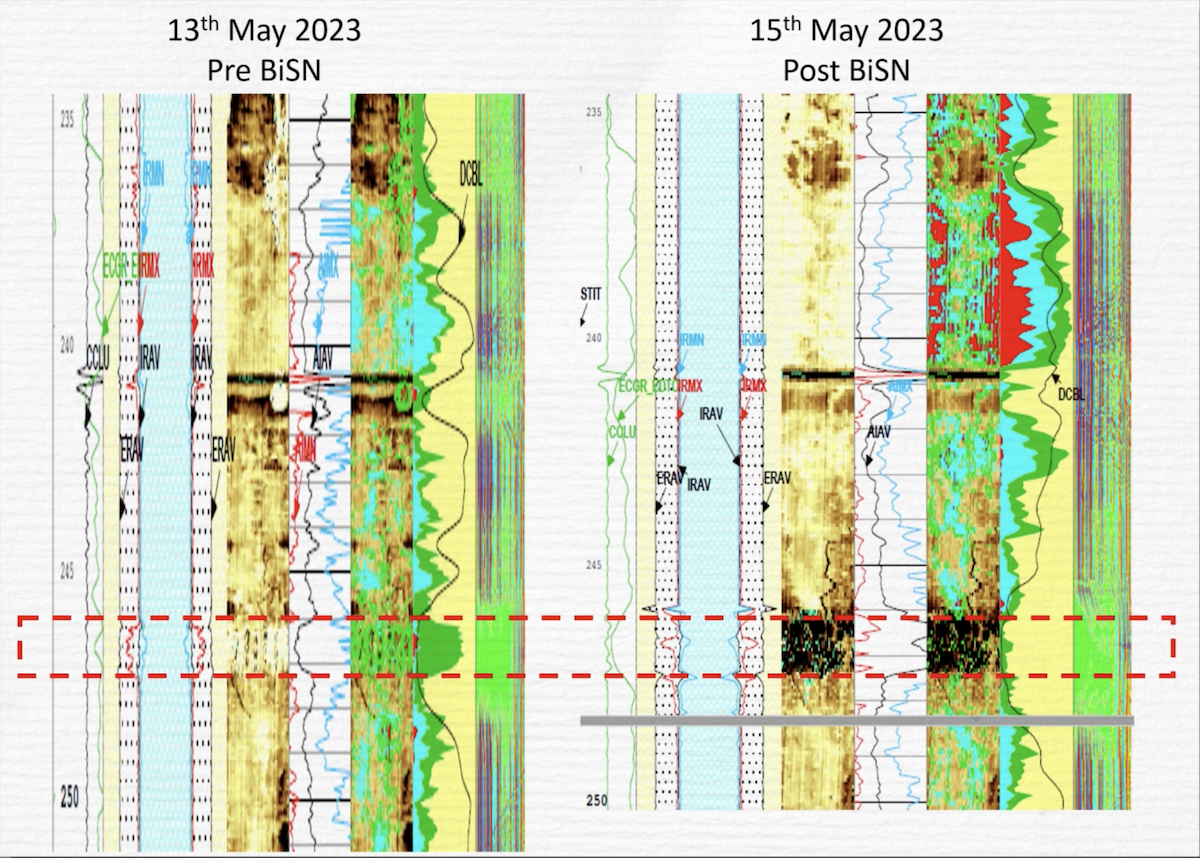

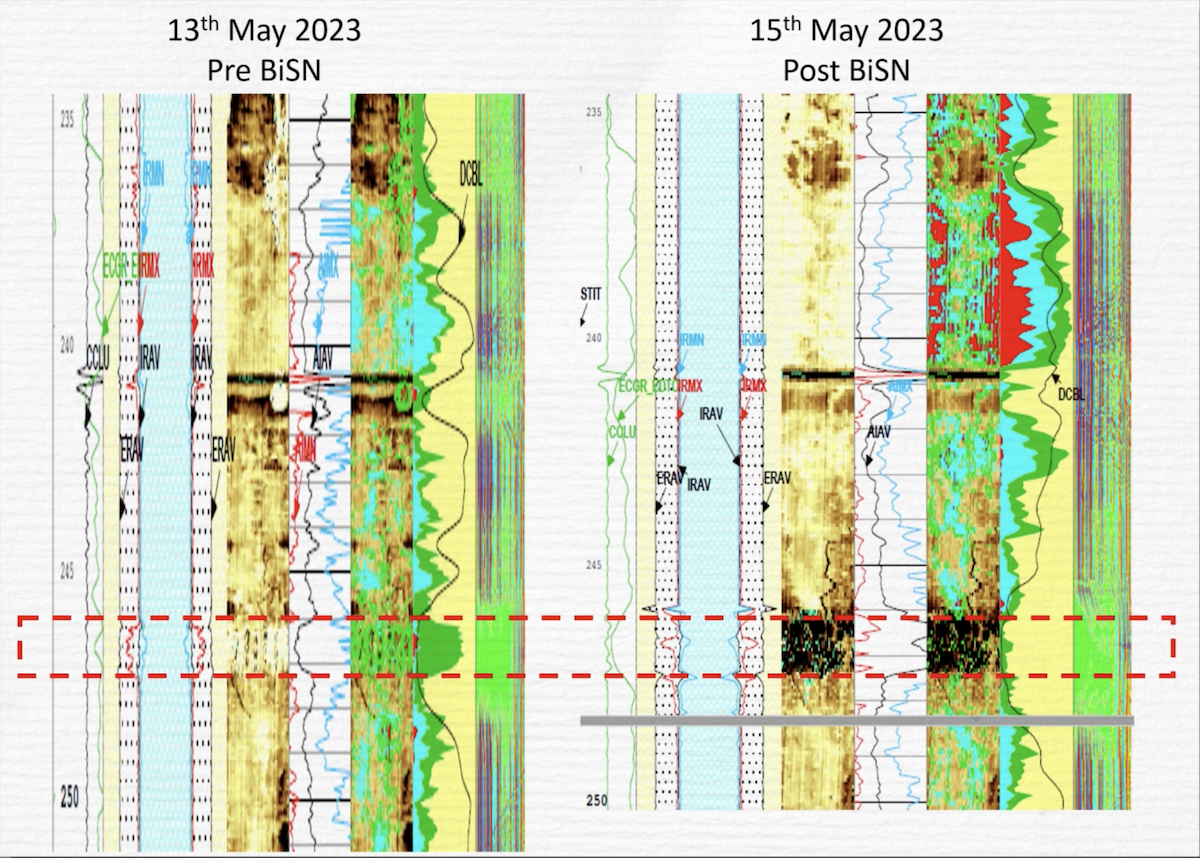

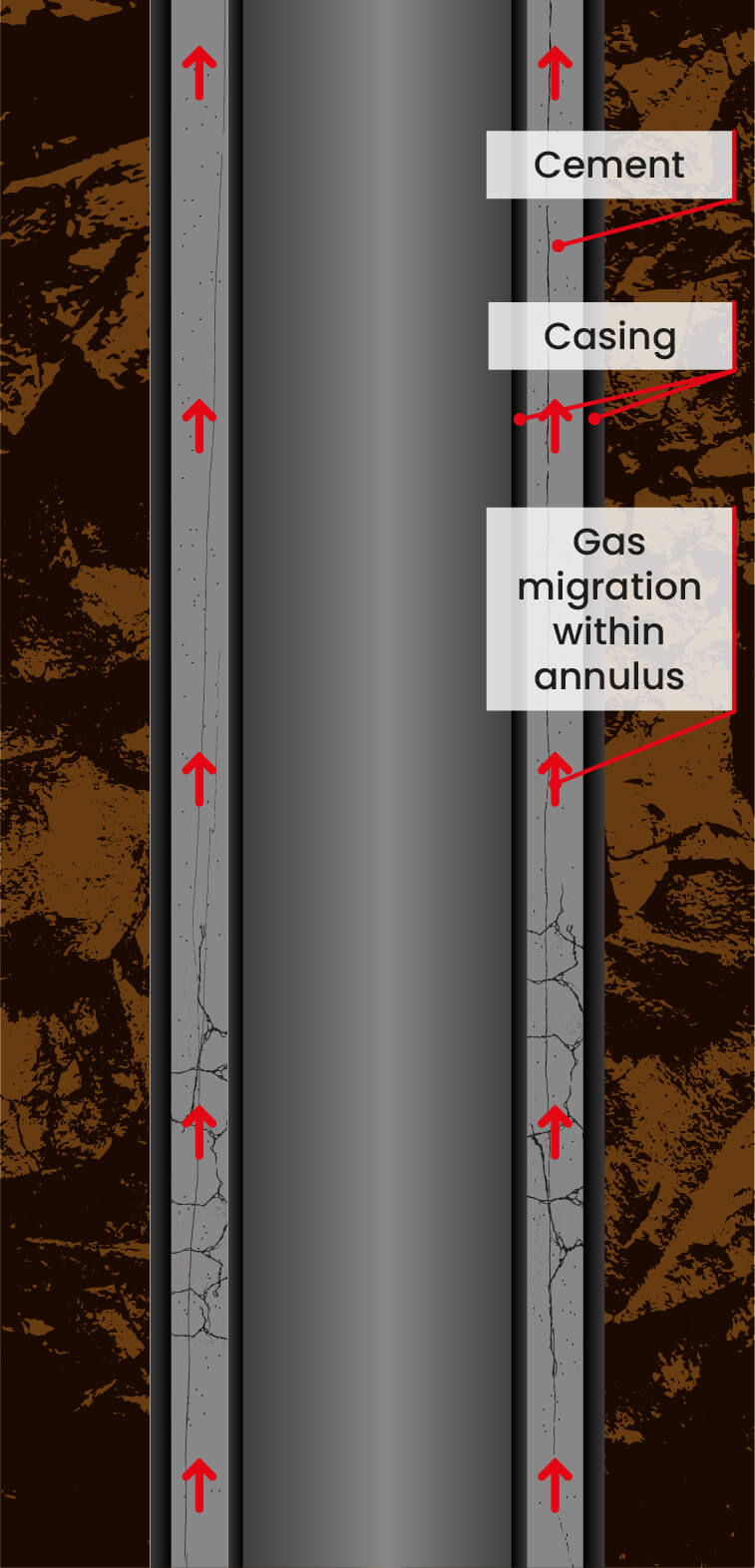

Sasol had run a baseline log showing that previous cement work was patchy and needed to find a rock-to-rock sealing solution. Thin cap rock in the region increased the difficulty of this task.

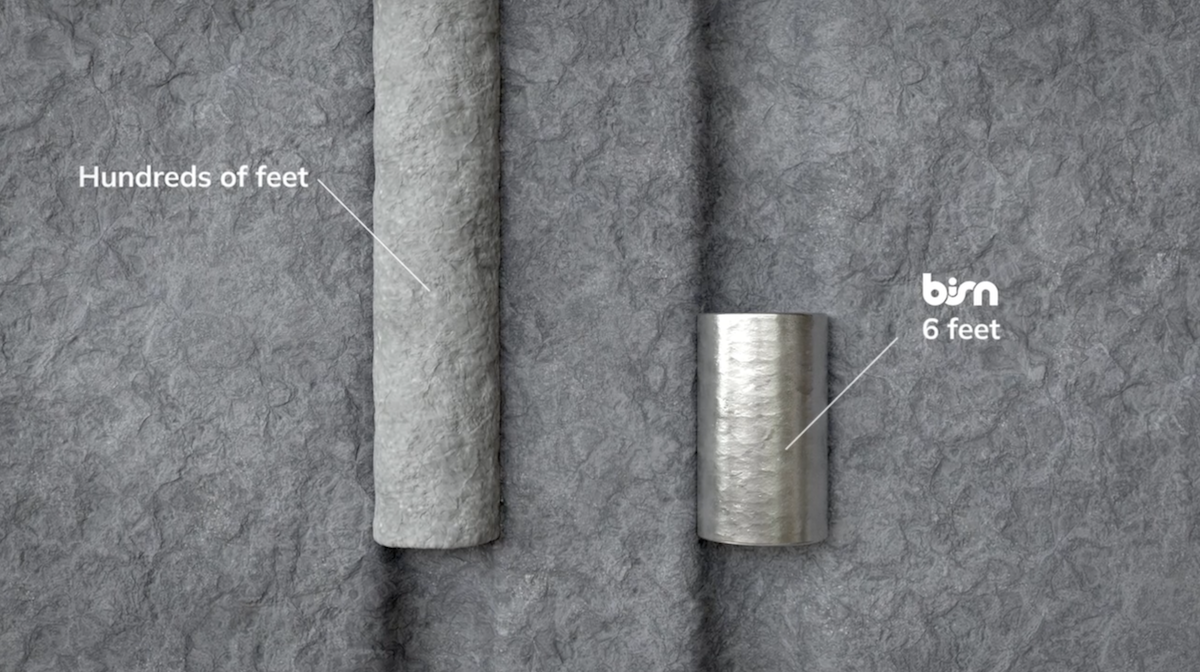

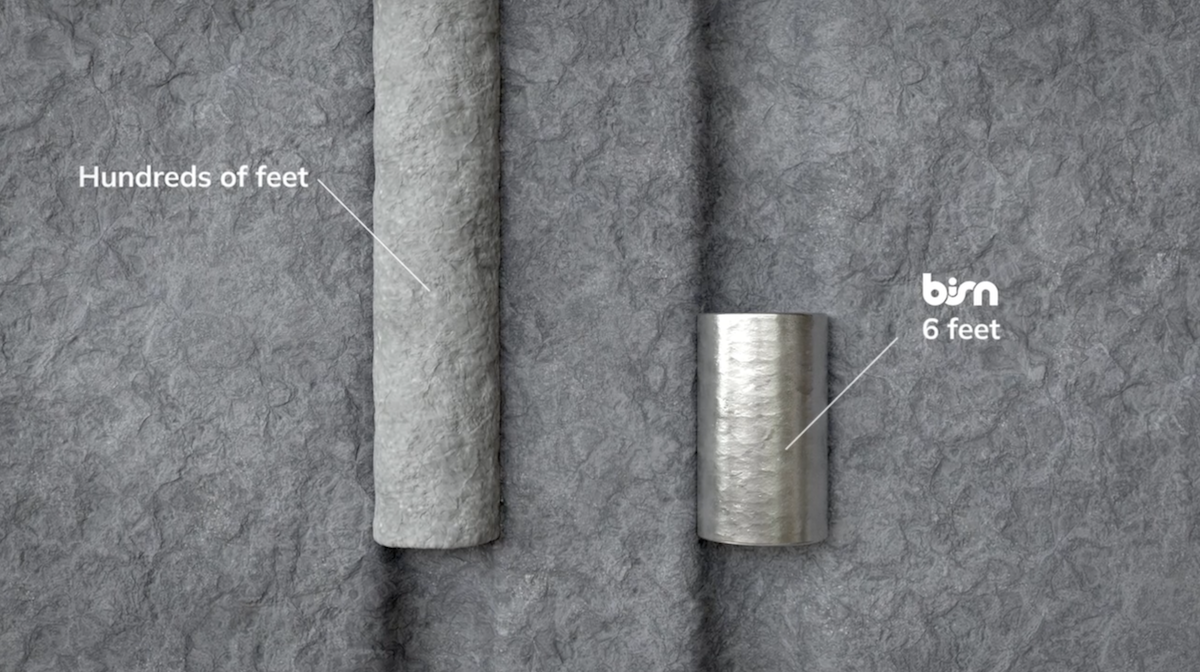

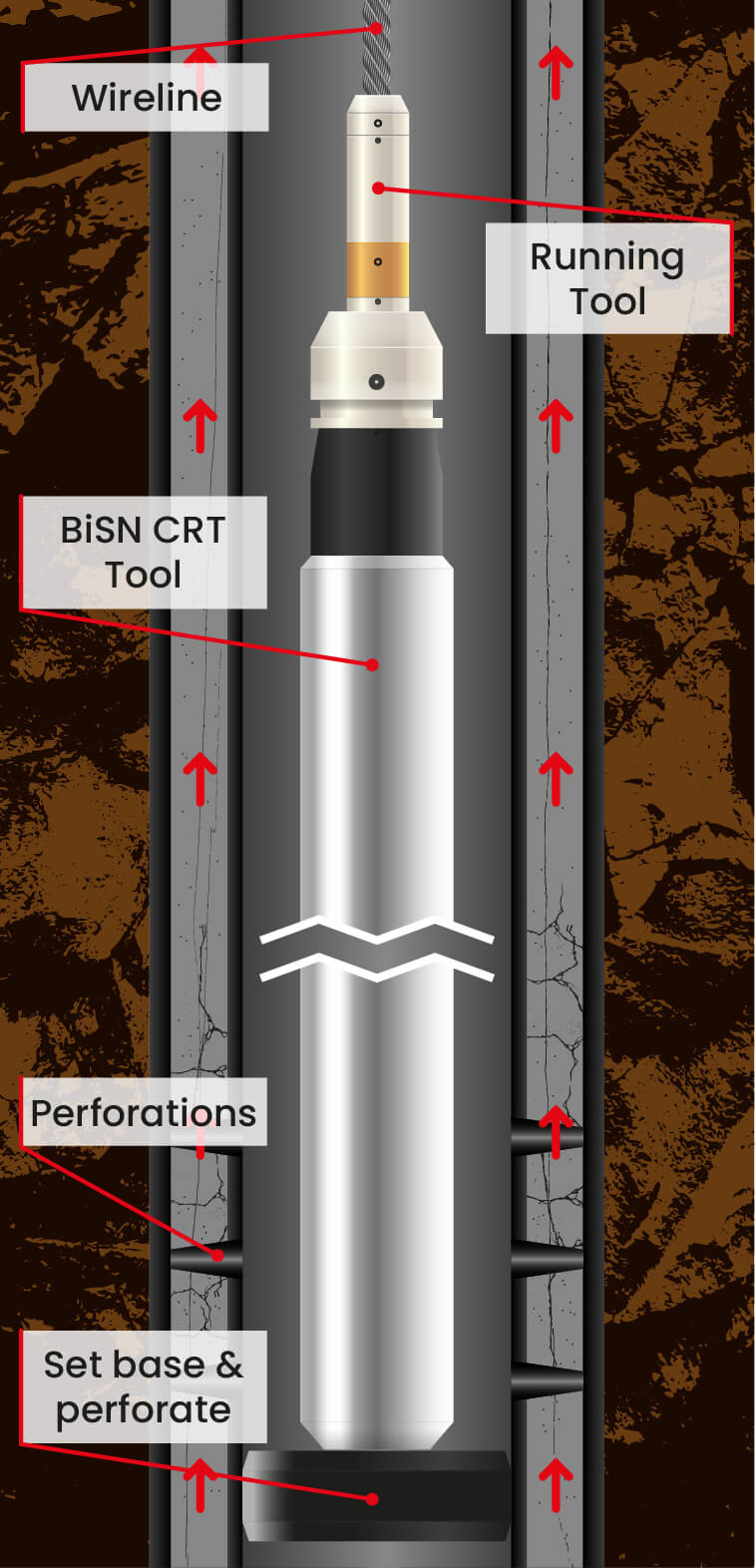

The decision was made to deploy Wel-lok™ technology via perforations in 9-5/8” casing with the objective of isolating formation activity from a gas bearing silt layer from shallower formations. BiSN was challenged to place a Wel-lok™ plug within a 10m thick shale layer identified as a suitable regional seal.

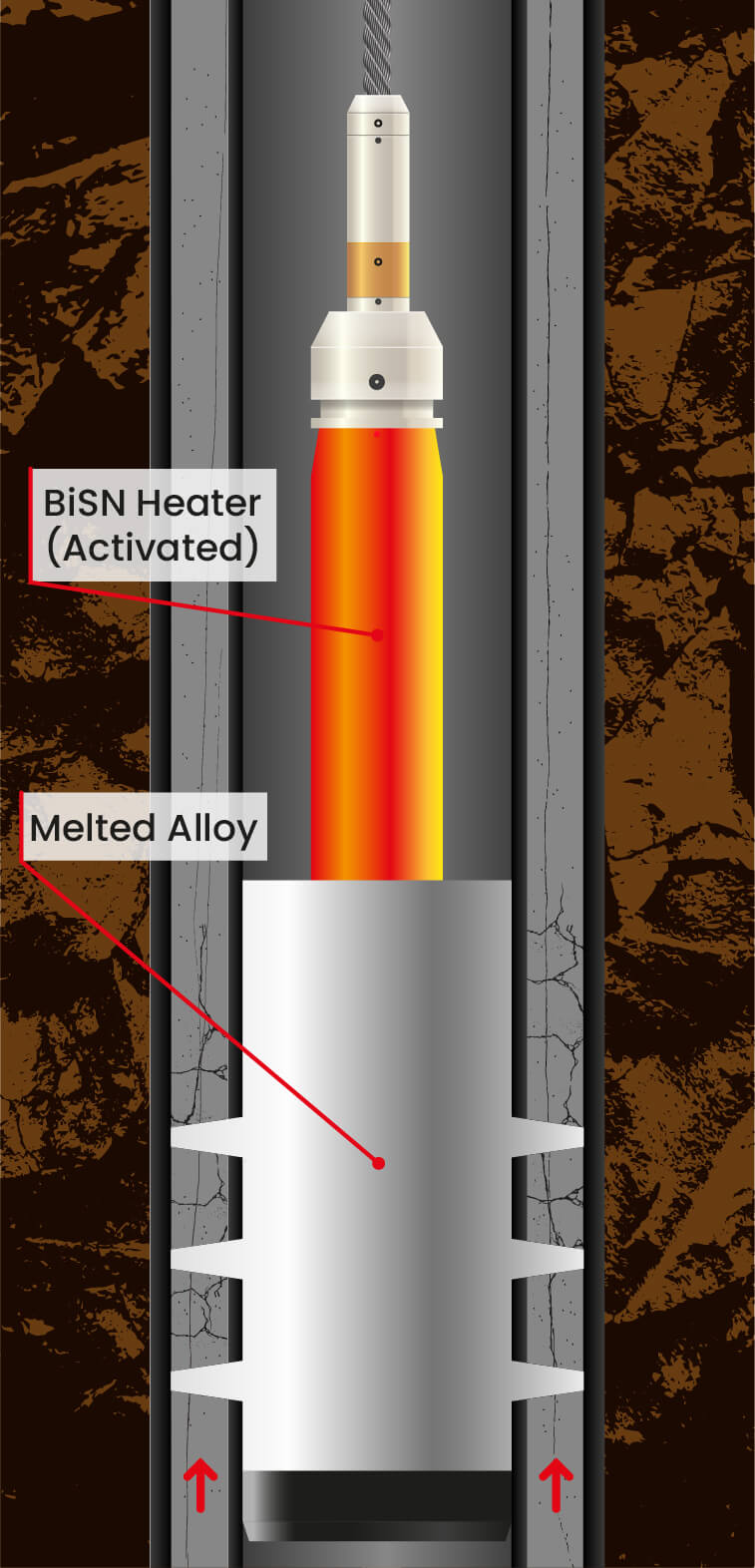

BiSN field engineers worked alongside a service partner and Sasol as a team effort to solve the downhole issue. First, the 9-5/8” casing was scraped, followed by a perforating gun run to provide access to the annulus. Next, a Wel-lok™ CRT tool was deployed and activated by a timer and hydrostatic switch.

“Sasol believes that BiSN alloy is a material which is far less prone to contamination vs traditional cement and can effect a far higher sealing capability within a shorter column height due to its expansion characteristics upon cooling. Upon setting, it far exceeded our expectations and we will continue to use BiSN technology in Sasol campaigns.” – Sandy Ferrari, Well Engineering Consultant, Sasol

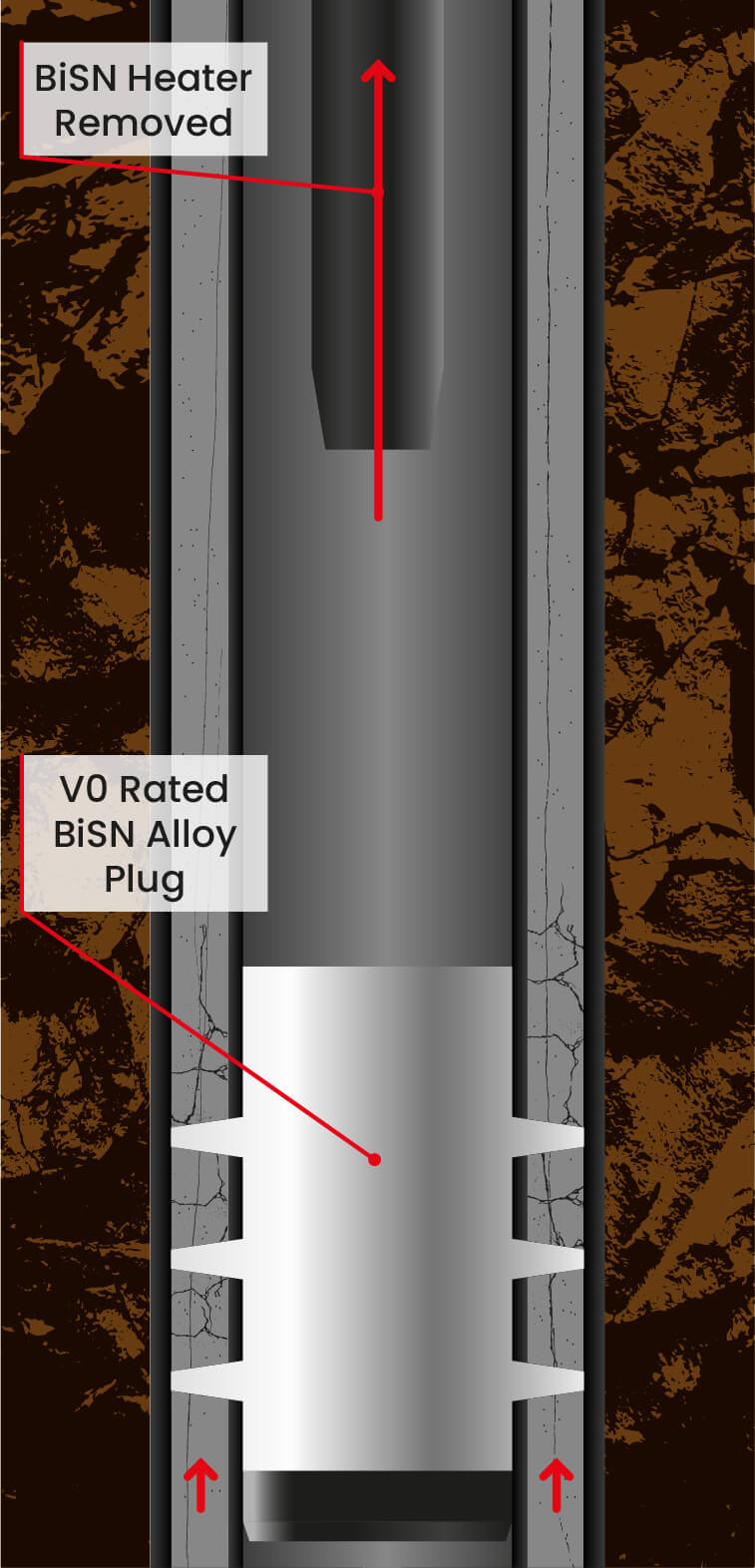

A Wel-lok™ plug was set downhole effectively and efficiently. Inside the wellbore the bismuth plug was milled out to run logging to determine the effectiveness of the operation. The following results were observed:

The following was observed by Sasol personnel:

“A key to success was the excellent collaboration between BiSN and Sasol from ordering the tools to the successful bismuth alloy installation. The openness in communication and transparency on both sides was vital to the deployment’s success.” – Klisthenis Dimitriadis, Well Engineering Manager, Sasol

The Wel-lok™ CRT (Cement Repair Tool) was developed to eliminate sustained casing pressure, or casing vent flow, in cemented annuli. Unlike traditional methods of perf and squeeze or perf and wash, this tool does not require any surface pumping pressure to squeeze or circulate the sealing material into place. The tool is also run rigless on electric line, sealing through casing perforations, so section milling is not required. The bismuth-based alloy has no porosity and solidifies to create a seal in minutes as opposed to hours with traditional cement and resins, eliminating the possibility of a micro-annulus being formed to allow future gas migration. If full bore access is required, it can be milled out and still maintain a gas tight seal in the annulus.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies