Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Well Abandonment with wel-lok™ CRT

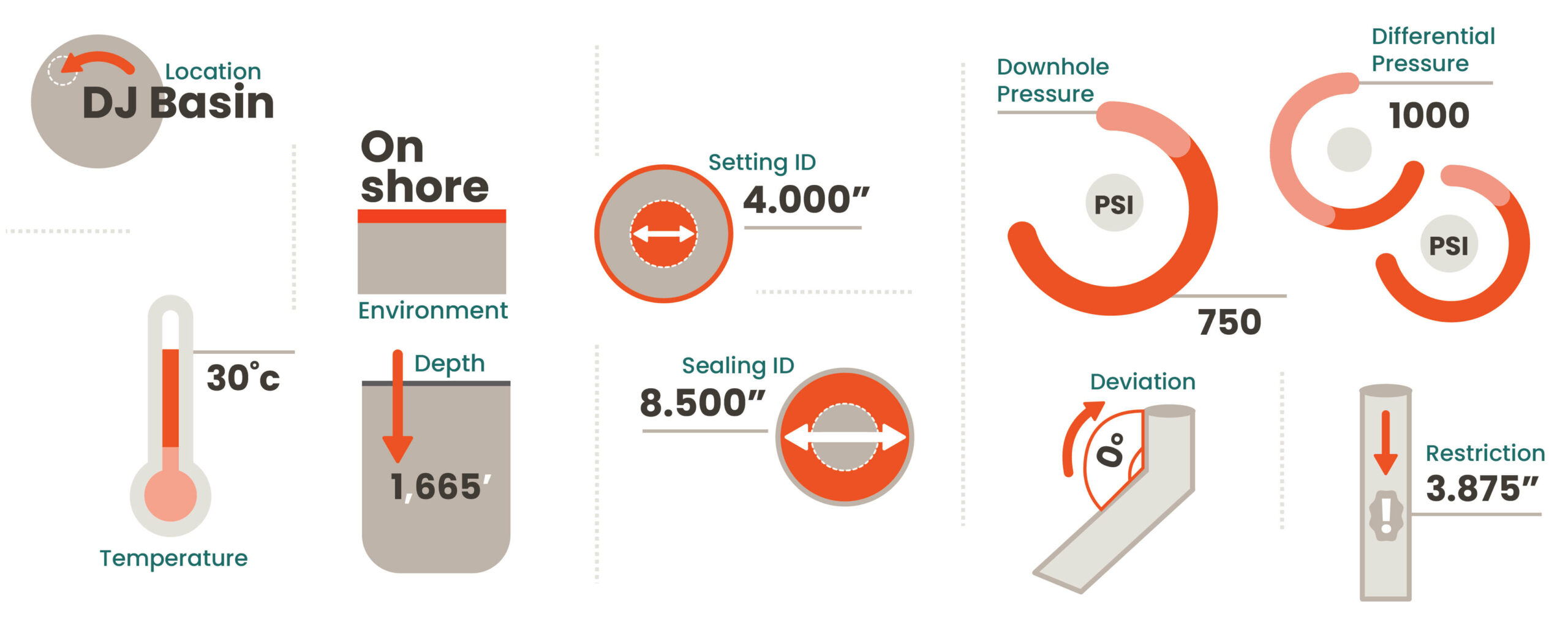

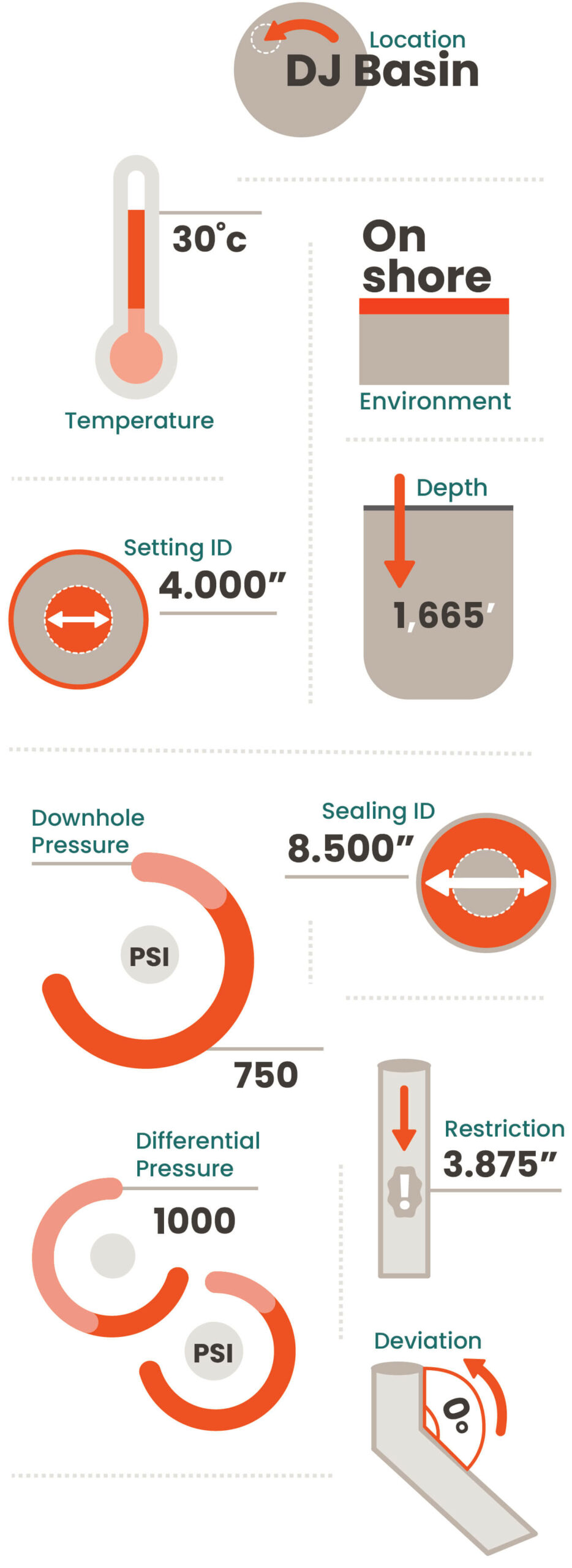

A well in the Colorado DJ Basin was experiencing Bradenhead pressure on the surface casing during the abandonment of the well. Previous attempts to eliminate this pressure with conventional methods had been unsuccessful. This is a common problem with many wells in the region.

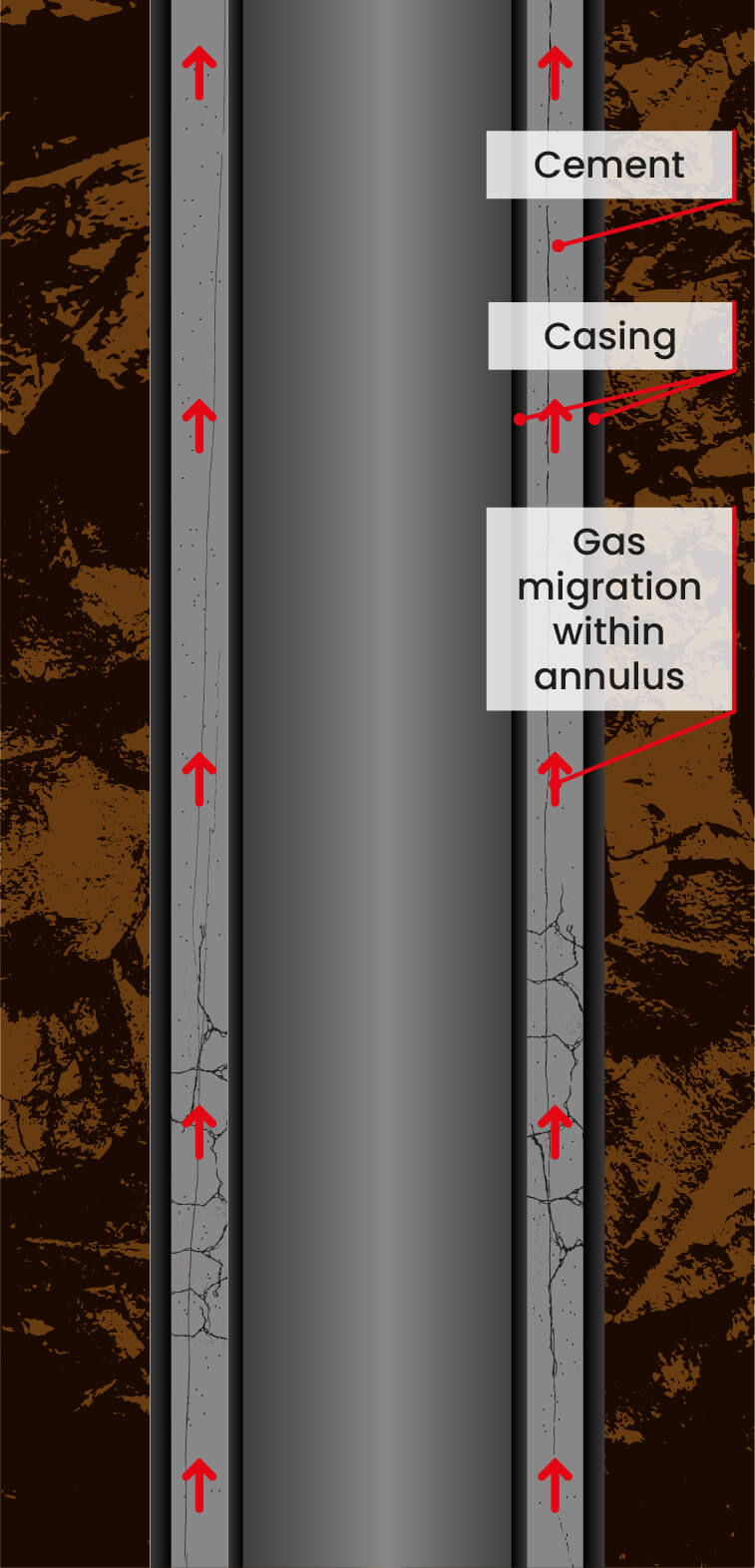

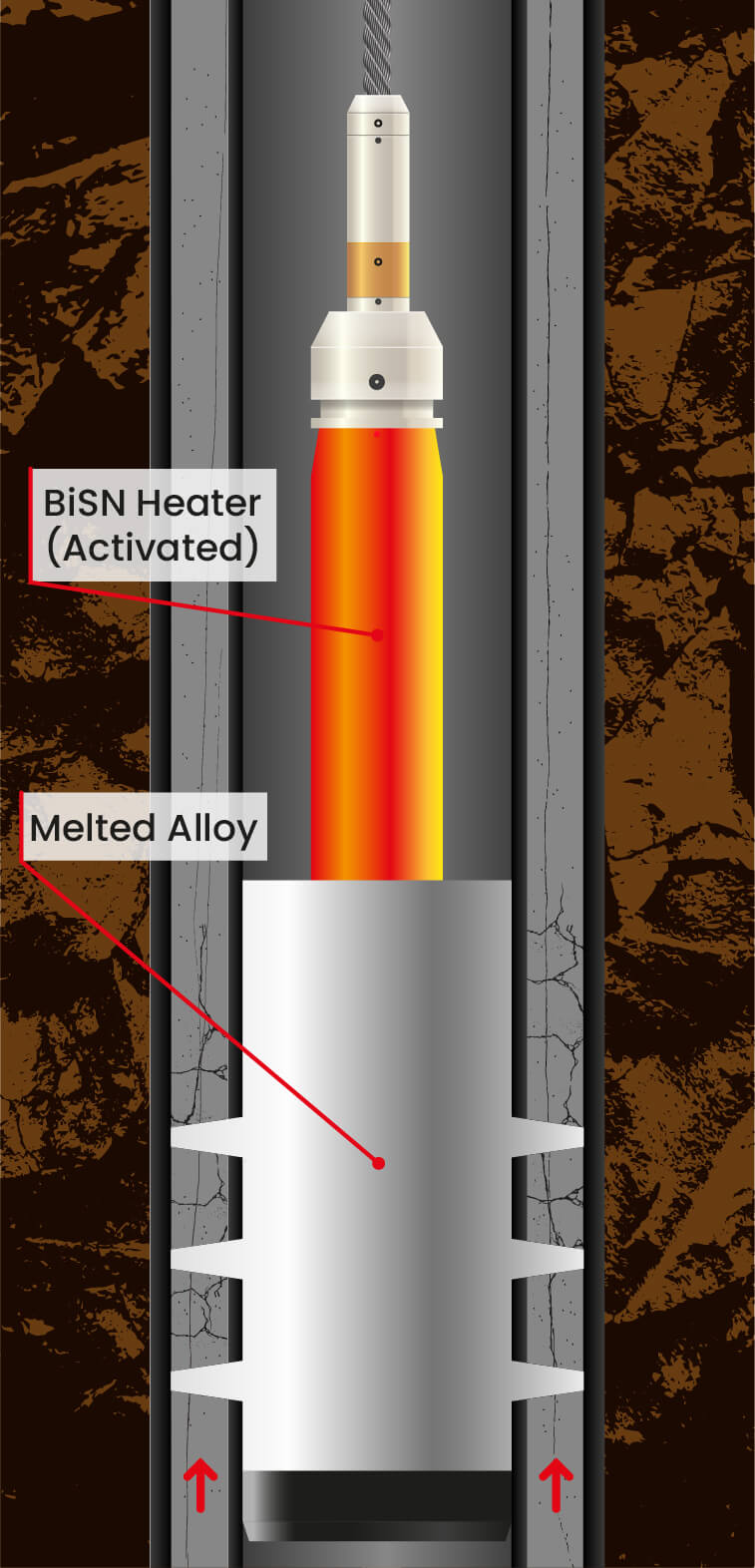

The production casing remained cemented inside the surface casing. With the gas flowing through channeled cement in the annulus, a flow path from inside the production casing into the annulus was required. The liquid bismuth will flow into and fill micro-annuli in cement if there is a path for it to flow through.

The 4 ½” production casing was section milled out to 9” open hole with an underreamer. A wel-lok™ CRT (Cement Repair Tool) was set inside the section milled window, sealing out to the open hole formation.

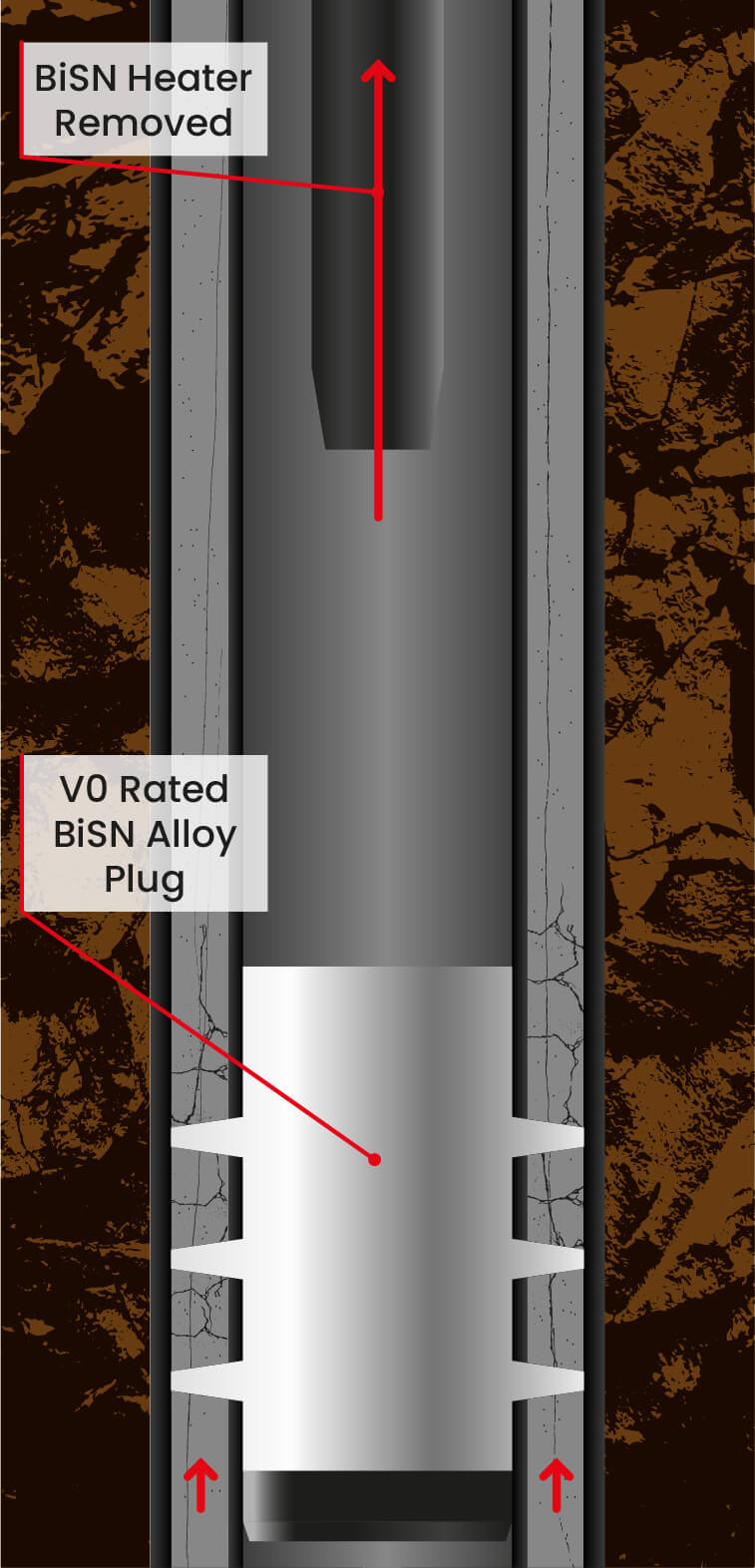

The BiSN CRT plug was successfully pressure tested and inflow tested, eliminating the Bradenhead pressure and all bubbles in the production casing. The client monitored the well for several days before completing the well abandonment. This was the first wel-lok™ CRT deployed and the first of many BiSN tools deployed to address Bradenhead pressure in the DJ Basin.

The wel-lok™ CRT (Cement Repair Tool) was developed to eliminate sustained casing pressure, or casing vent flow, in cemented annuli. Unlike traditional methods of perf and squeeze or perf and wash, this tool does not require any surface pumping pressure to squeeze or circulate the sealing material into place. The tool is also run rigless on electric line, sealing through casing perforations, so section milling is not required. The bismuth-based alloy has no porosity and solidifies to create a seal in minutes as opposed to hours with traditional cement and resins, eliminating the possibility of a micro-annulus being formed to allow future gas migration. If full bore access is required, it can be milled out and still maintain a gas tight seal in the annulus.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies