Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Well Intervention with Wel-lok™ WSO

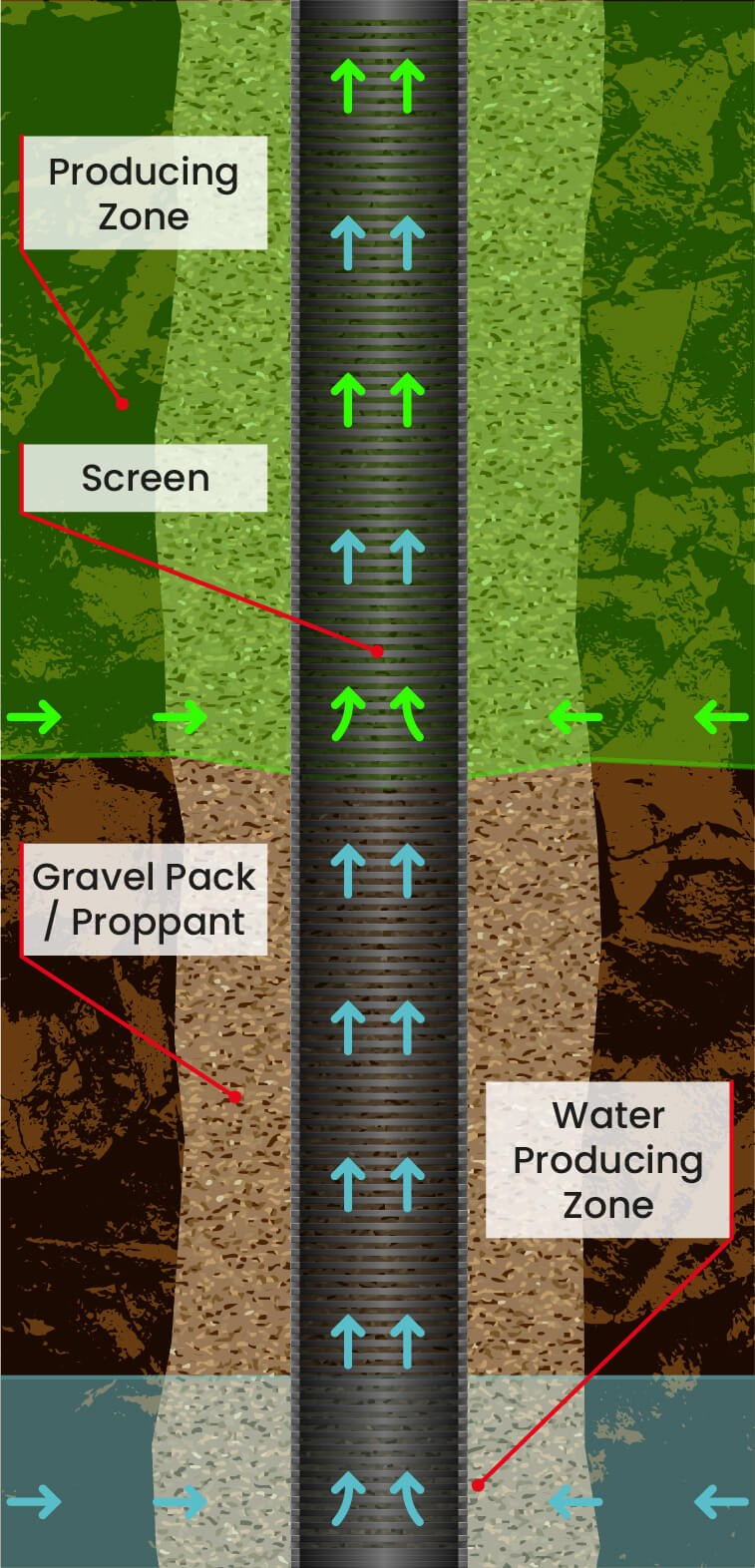

Provide a seal in the production string and annulus to shut off a lower water producing zone.

Traditional methods of reducing water production from a well included setting multiple bridge plugs in the production string or perforating the production string and squeezing cement or a resin. Bridge plugs only baffle the water, slowing it down but not stopping it, as they cannot seal the annulus outside of the production string. Resins require perforations to access the annulus, damaging the production string.

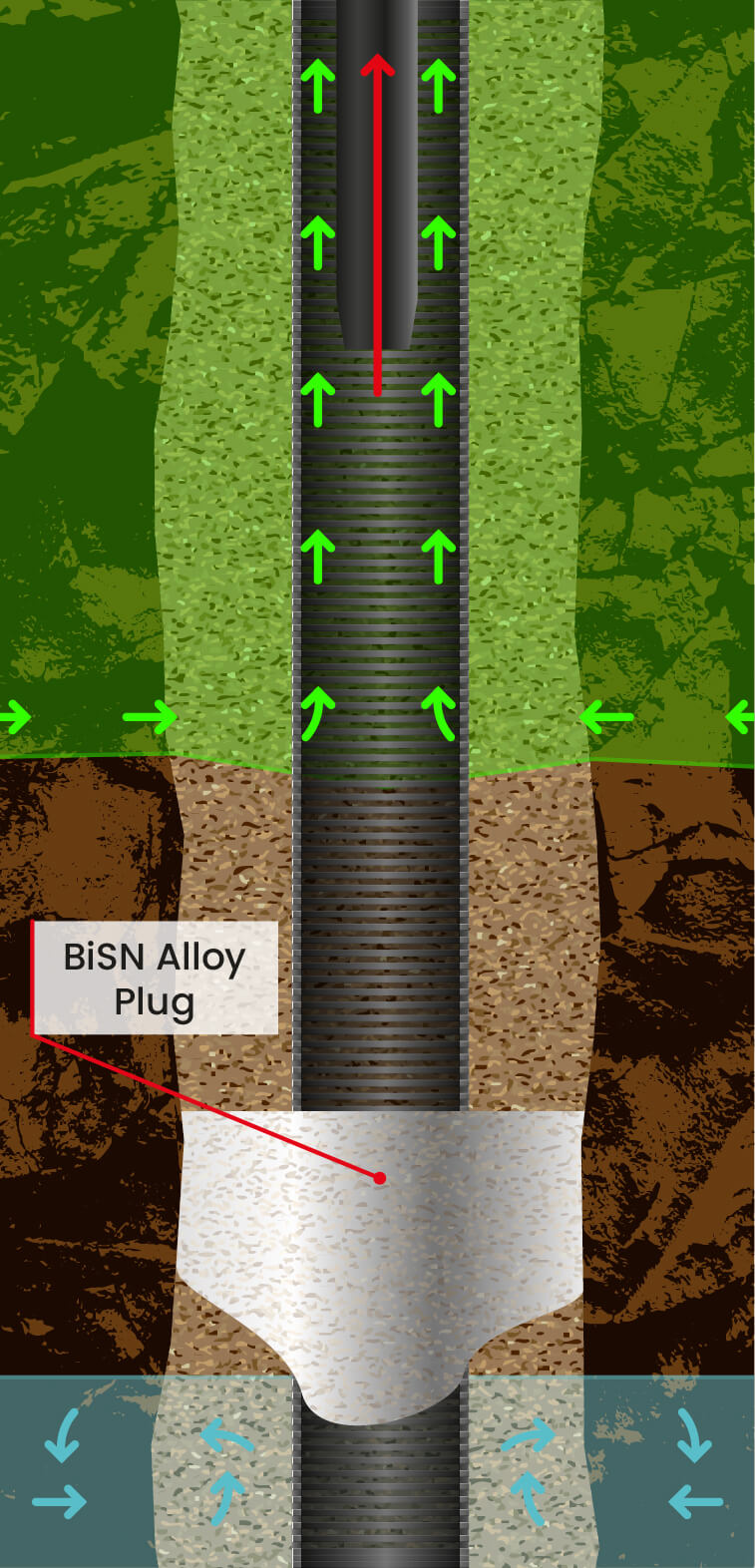

Initial water production on the well was in excess of 50%. After setting the BiSN tool, water production was reduced to under 25%.

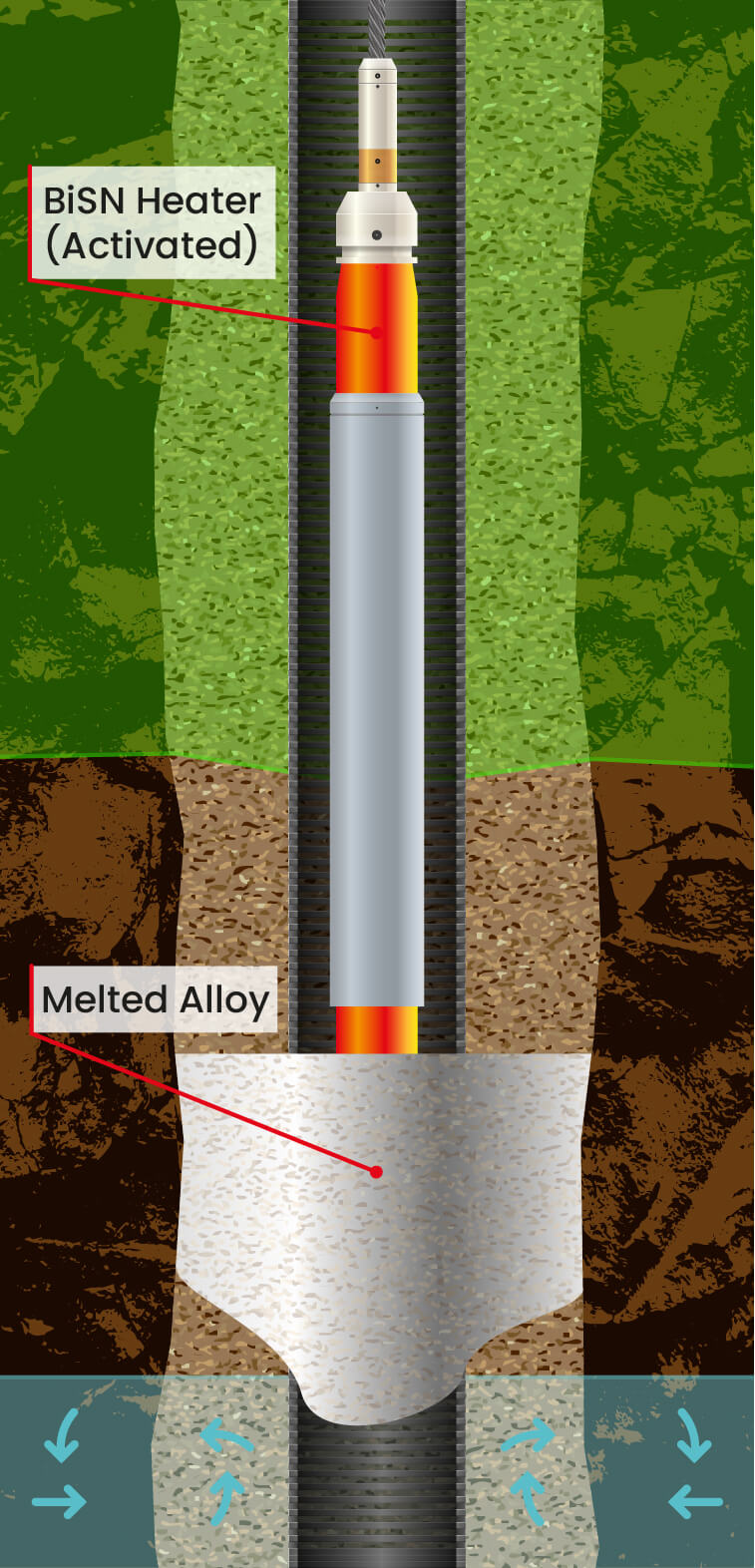

The Wel-lok™ WSO (Water Shut Off) has been specifically developed to reduce unwanted water production from wells with sand screen and open hole gravel pack completions (OHGP). Unlike any other solution on the market, the Wel-lok™ WSO tool seals the annulus and the wellbore in one operation without the need to perforate the sandscreen or squeeze the alloy into the open hole annulus. The melted alloy fills inside the completion and in the annulus to form a metal to metal sealing solution that is seamless, significantly reducing unwanted water production.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies