Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Well Intervention with Wel-lok™ Perf-lok

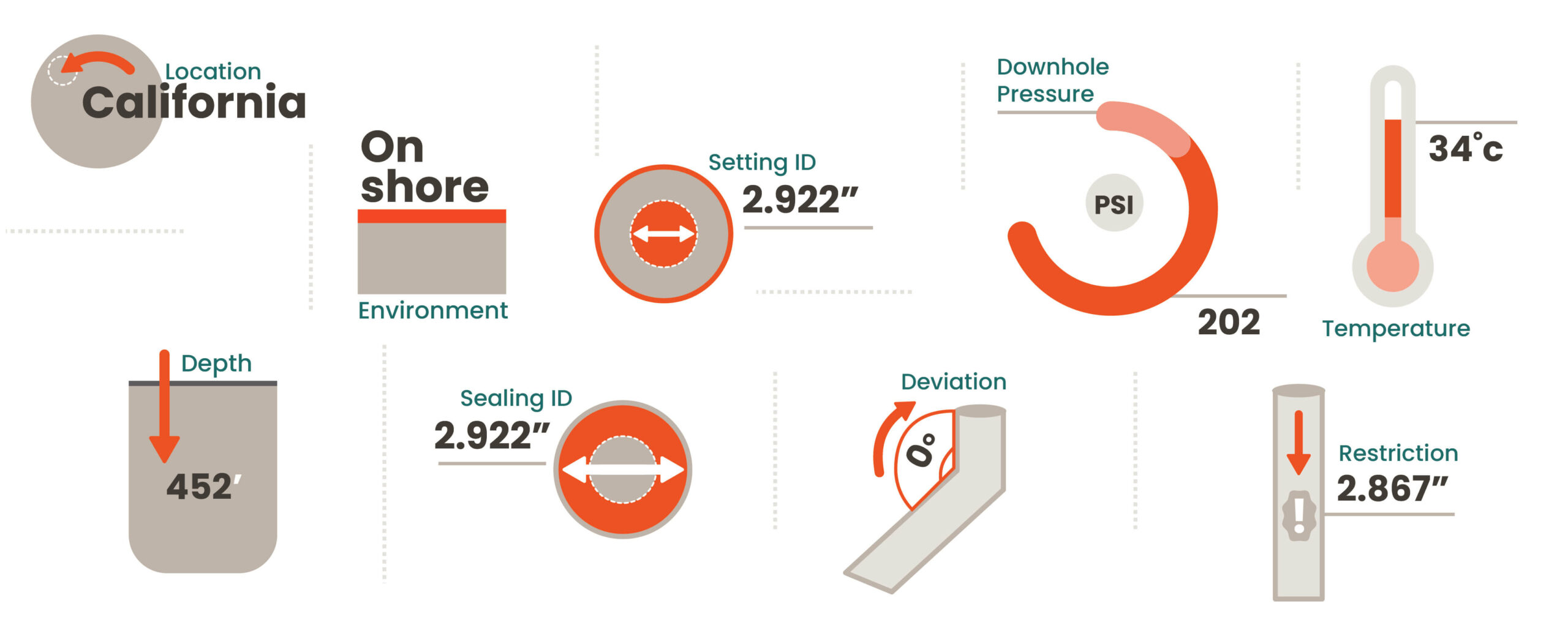

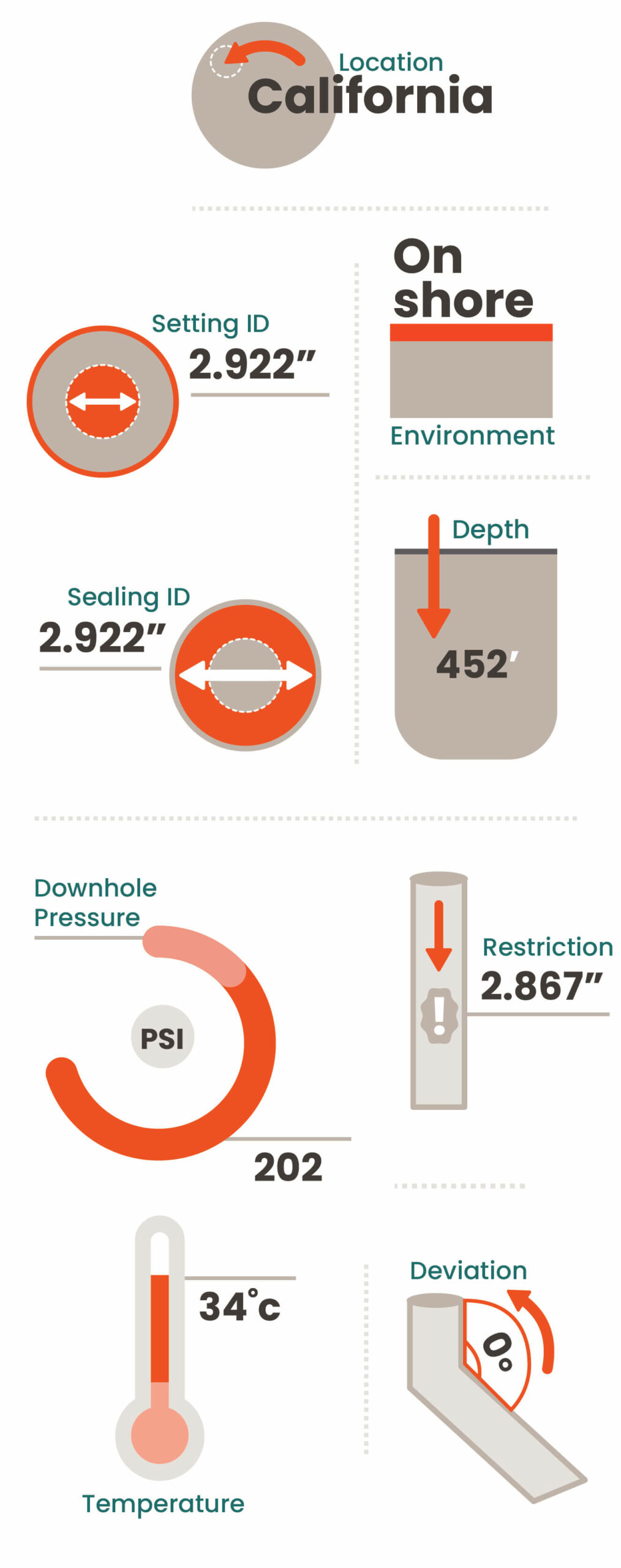

Operators in Bakersfield, California, utilize steam injection wells as part of their operations. Single holes are perforated in a cemented casing string at various depths, allowing operators to inject steam into the formation at different depths to improve production on nearby wells. Over time, the majority of the steam will begin to inject into one of these holes, preventing steam from entering the rest of the perforations in the well. When this occurs, it is necessary to plug off the “thief” hole. The traditional method of doing this was to place a casing patch over the hole. This created a restriction in the well and over time the patches began to leak due to the high temperature steam.

Temperature in these wells during steam injection can reach as high as 330°F (165°C) and the operator wanted full bore access in the casing after the hole was plugged. Although steam could be injected into the zone, injecting a viscous fluid like cement or resin was difficult and due to the downhole temperature often unreliable.

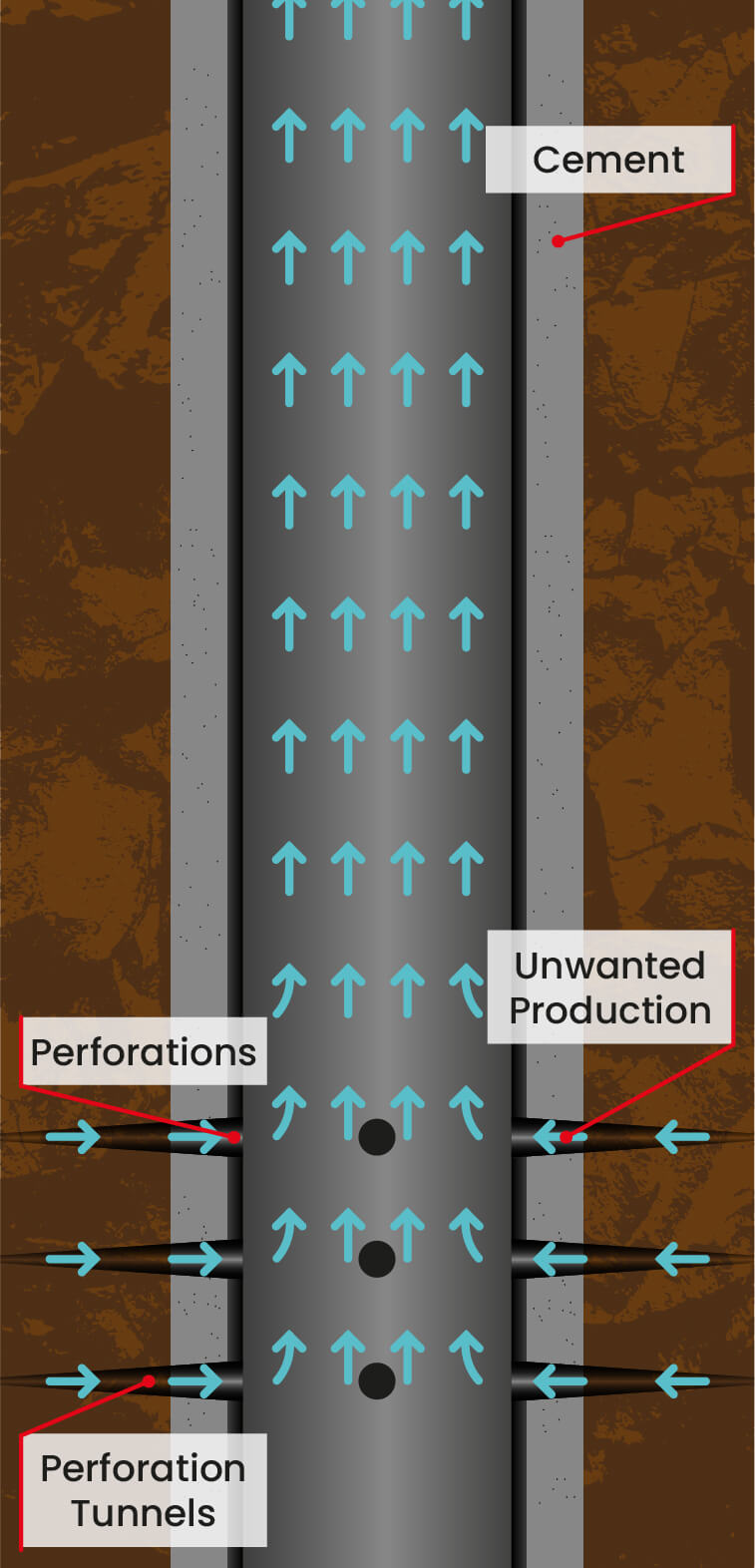

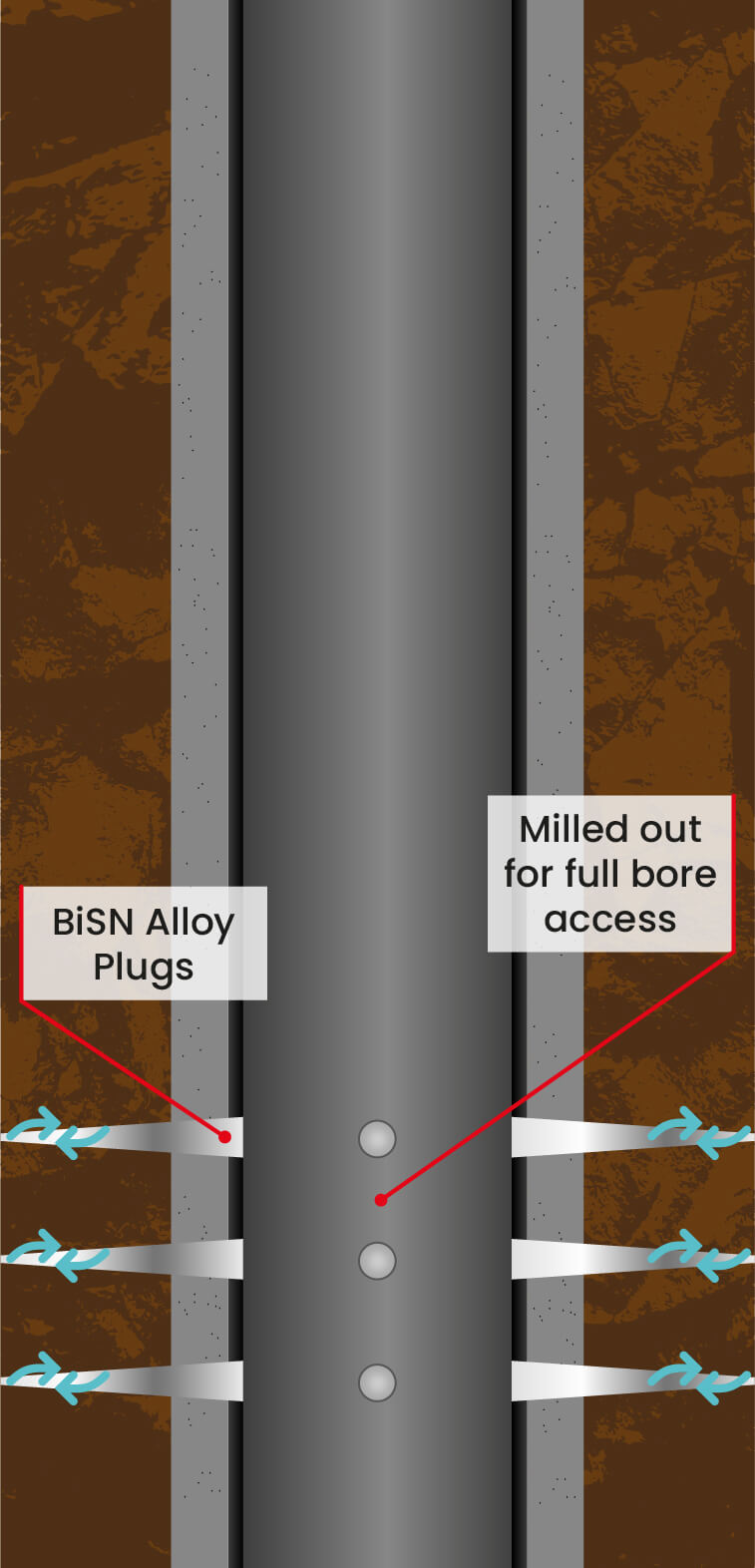

Utilizing a wireline unit, a Wel-lok™ Perf-lok was set inside the 3 ½” casing across the ¼” perforation hole. The bismuth alloy was melted, flowed into the perforation hole via gravity (no injection required) and expanded after solidifying to plug the hole. The remaining bismuth alloy plug inside the 3 ½” casing was milled out leaving only an alloy plug in the perforation hole and full bore access inside the casing.

After successfully setting and milling out the alloy plug, an injection survey was performed. This survey showed the “thief” hole had been plugged and all the steam was being injected into perforations deeper in the well, just as the client had requested.

The Wel-lok™ Perf-lok was developed to isolate perforations in a cased hole completion for zonal isolation or well P&A. Unlike typical cement squeezes traditionally used for this purpose, the Perf-lok™ does not require squeezing as it is flows into the perforation tunnels by gravity due to its viscosity and density. Applying pressure to squeeze the cement can often cause the perforations to collapse and eliminate the ability to fill the entire void. The created plug can also be milled out inside the casing, maintaining a seal inside the perforations through its unique expansion properties.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies