Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Well Abandonment with Wel-lok™ TS

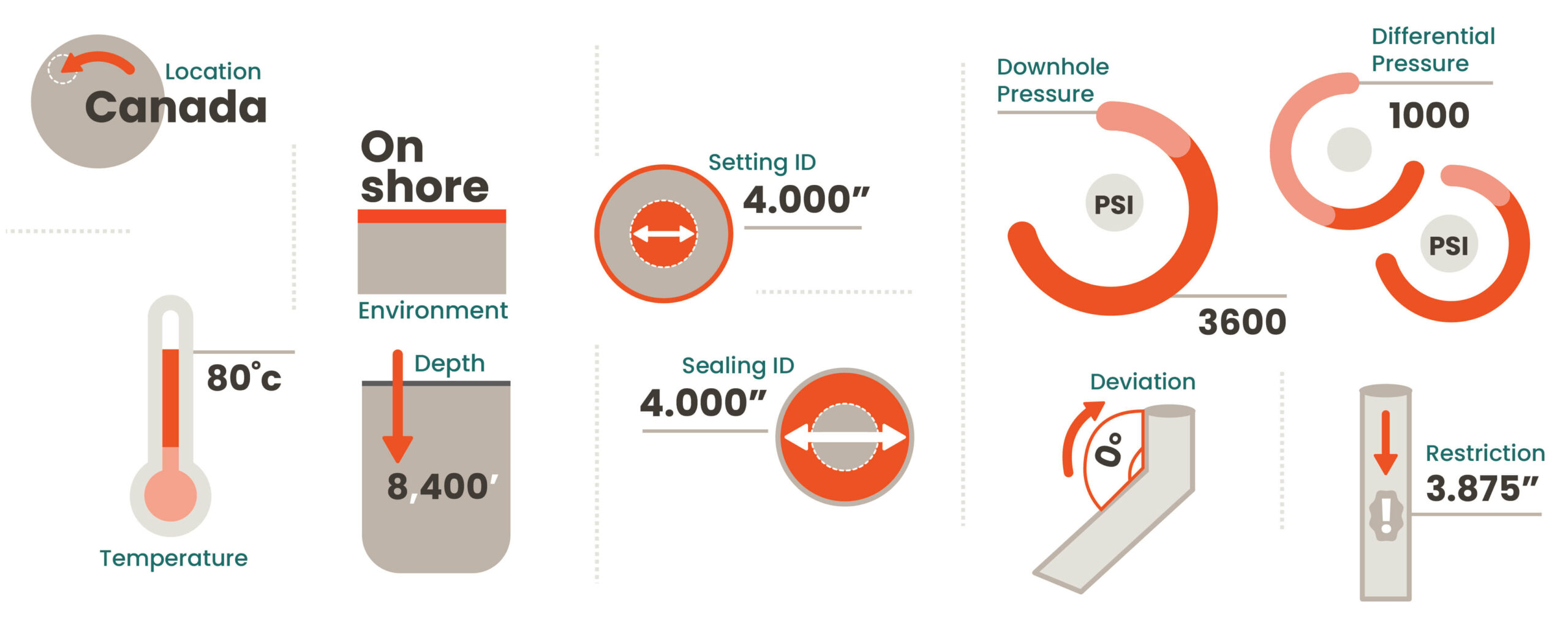

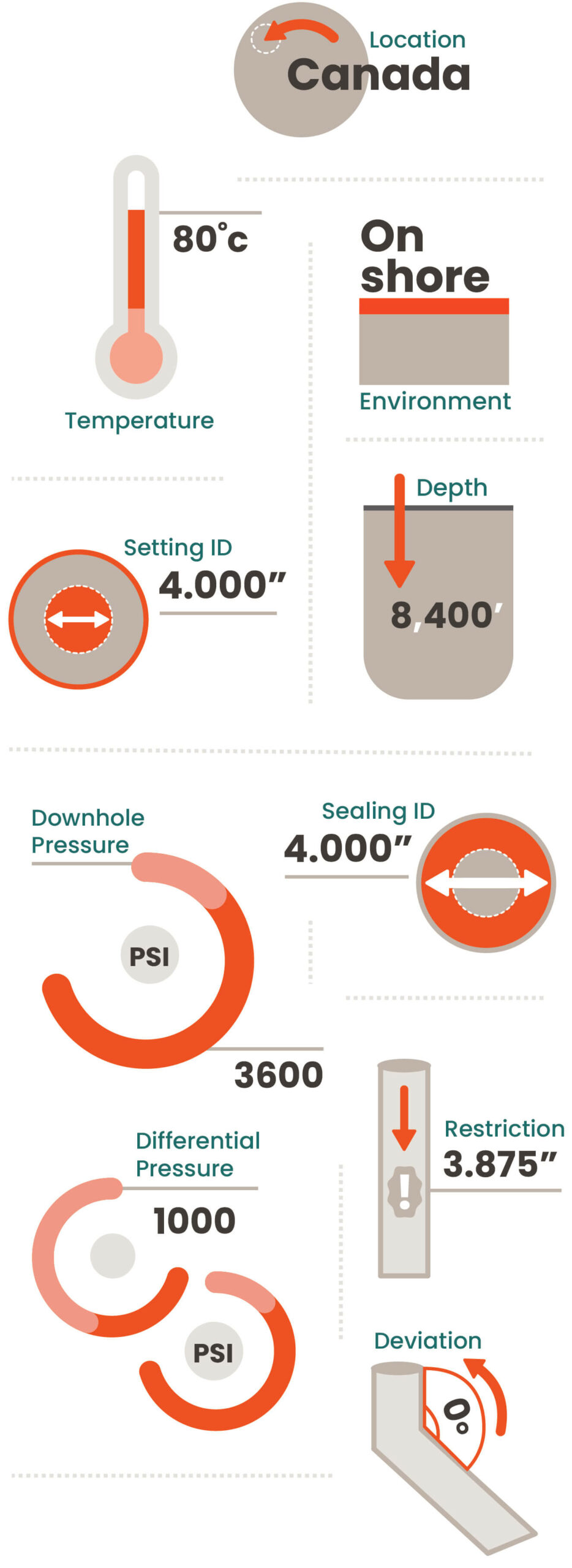

A client had attempted to abandon the producing zone of a well with traditional methods of setting a bridge plug inside the 4 ½” production casing and spotting cement on top. The production casing continued to build pressure and bubble were seen at surface, preventing the client from continuing their abandonment of the well.

Provide a permanent, gas tight seal.

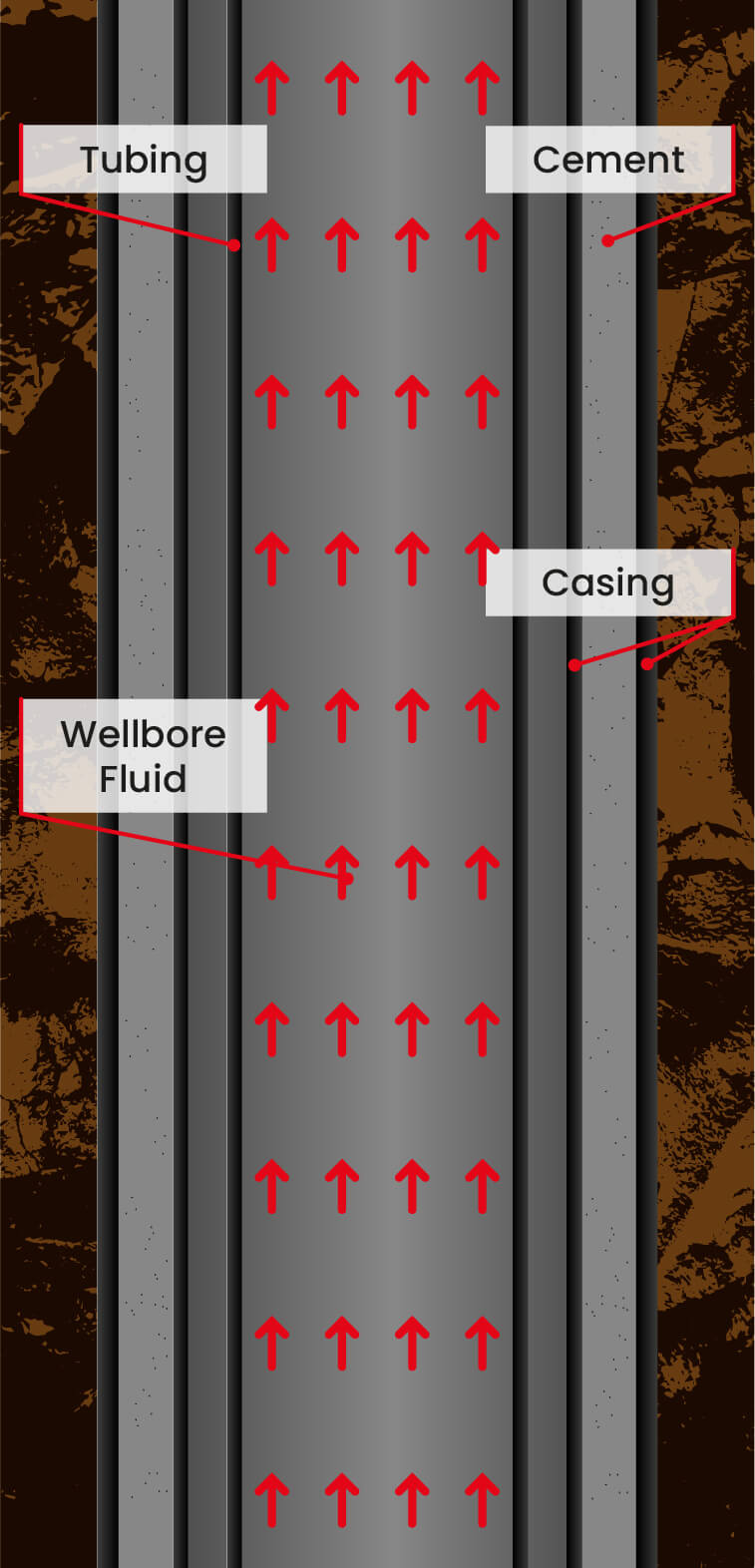

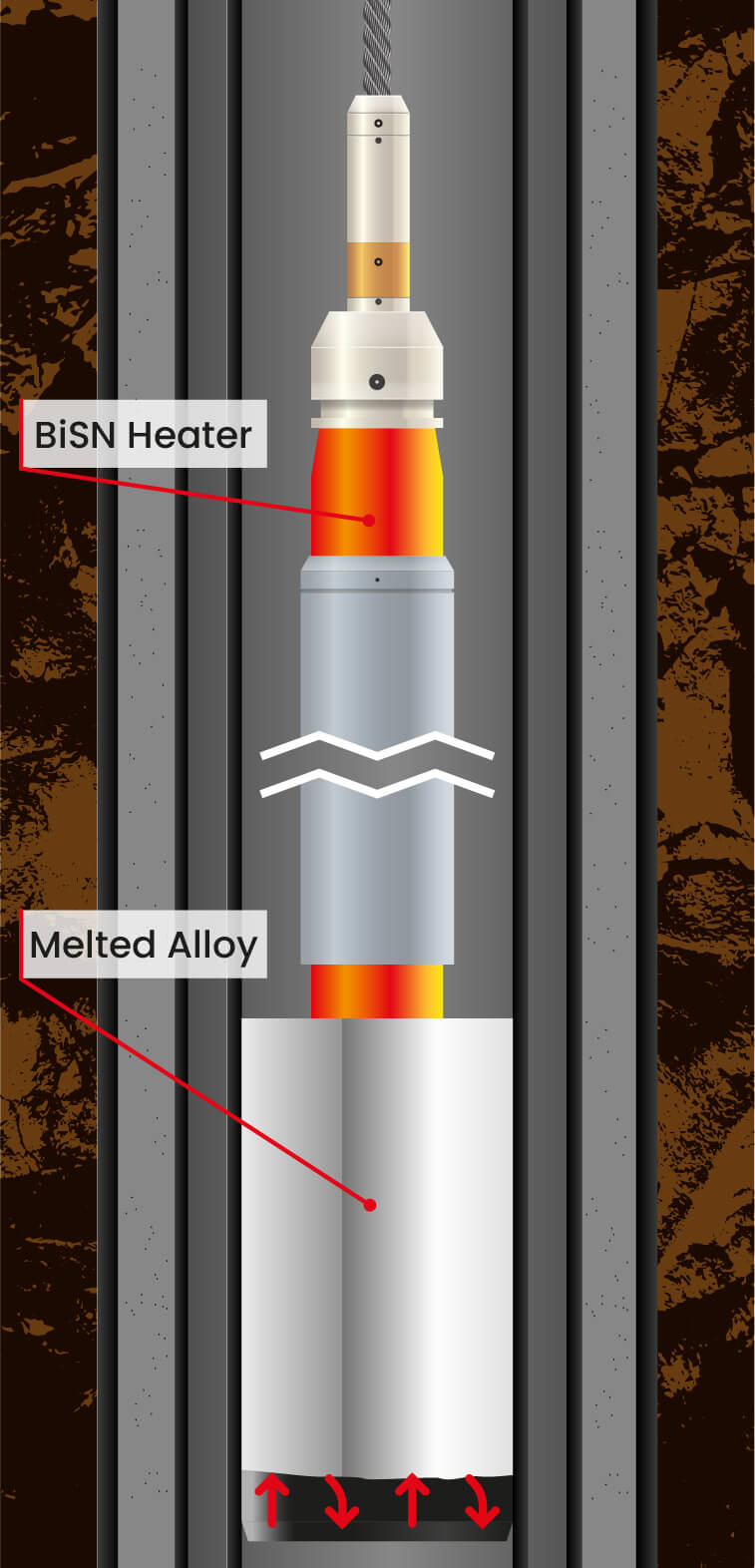

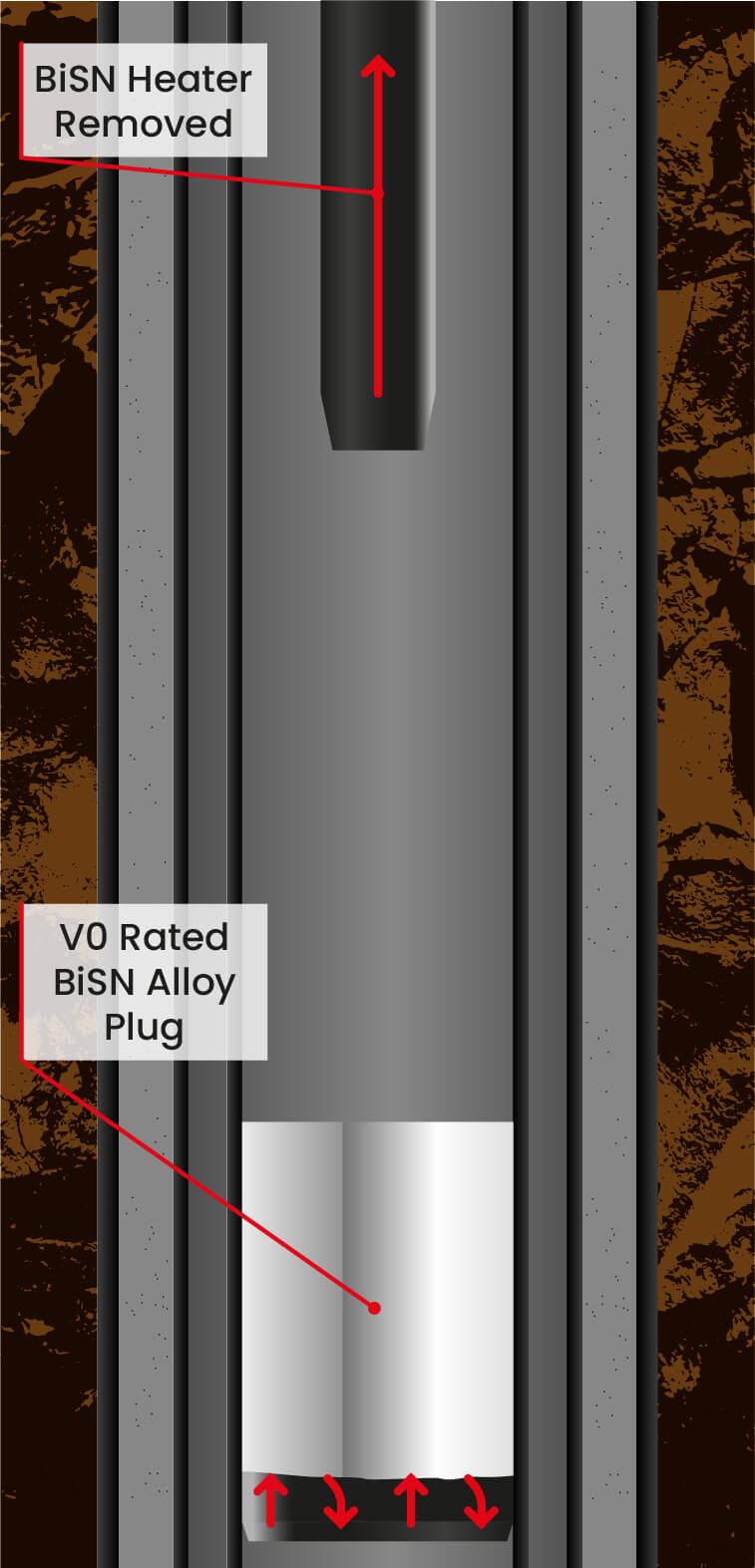

Wel-lok™ TS was set inside the 4 ½” production casing to provide a permanent, gas tight seal in the well.

After being set in the well the seal was successfully inflow tested with no increase in pressure or bubbles over a 10-day period. Previous monitoring had show pressure build up and gas bubbles at surface within 24 hours prior to setting the TS. This was the first commercial field run of BiSN’s Wel-lok™ technology in Canada.

The Wel-lok™ TS (Tubing Seal) was developed to overcome the shortcomings of traditional methods, using bridge plugs and cement during well abandonment. It is typically run on electric line but can be deployed on a slick line or coil tubing as well. It can pass through small restrictions such as damaged or crushed tubing, yet still create the gas tight seal. It has a higher expansion ratio than conventional plugs, higher pressure ratings than inflatable packers and gas blocking abilities that cement cannot match.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies