Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Well Completion with Wel-lok™ TDAP

A common issue in the DJ Basin, and throughout the world, is Bradenhead (or surface casing) pressure. It is caused by cement channeling in the production by surface casing annulus and can lead to costly interventions and abandonments over the life of a well. One operator in the DJ Basin decided to address this issue up front, during the original well construction, implementing this proactive solution on all new drill wells going forward.

To avoid disruption to the well and damage to the casing during an intervention, the solution must be implemented before there is an issue, as part of the original casing program.

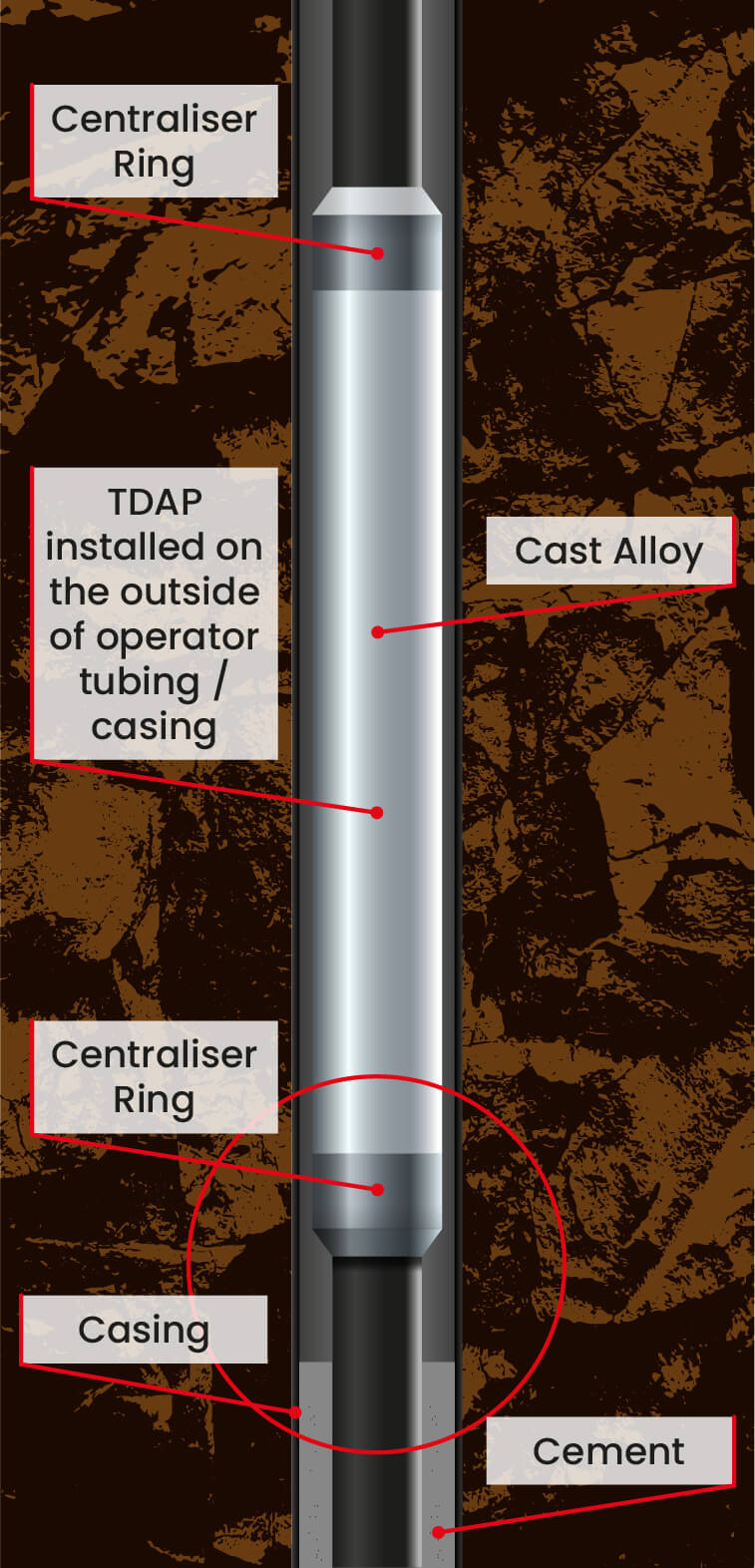

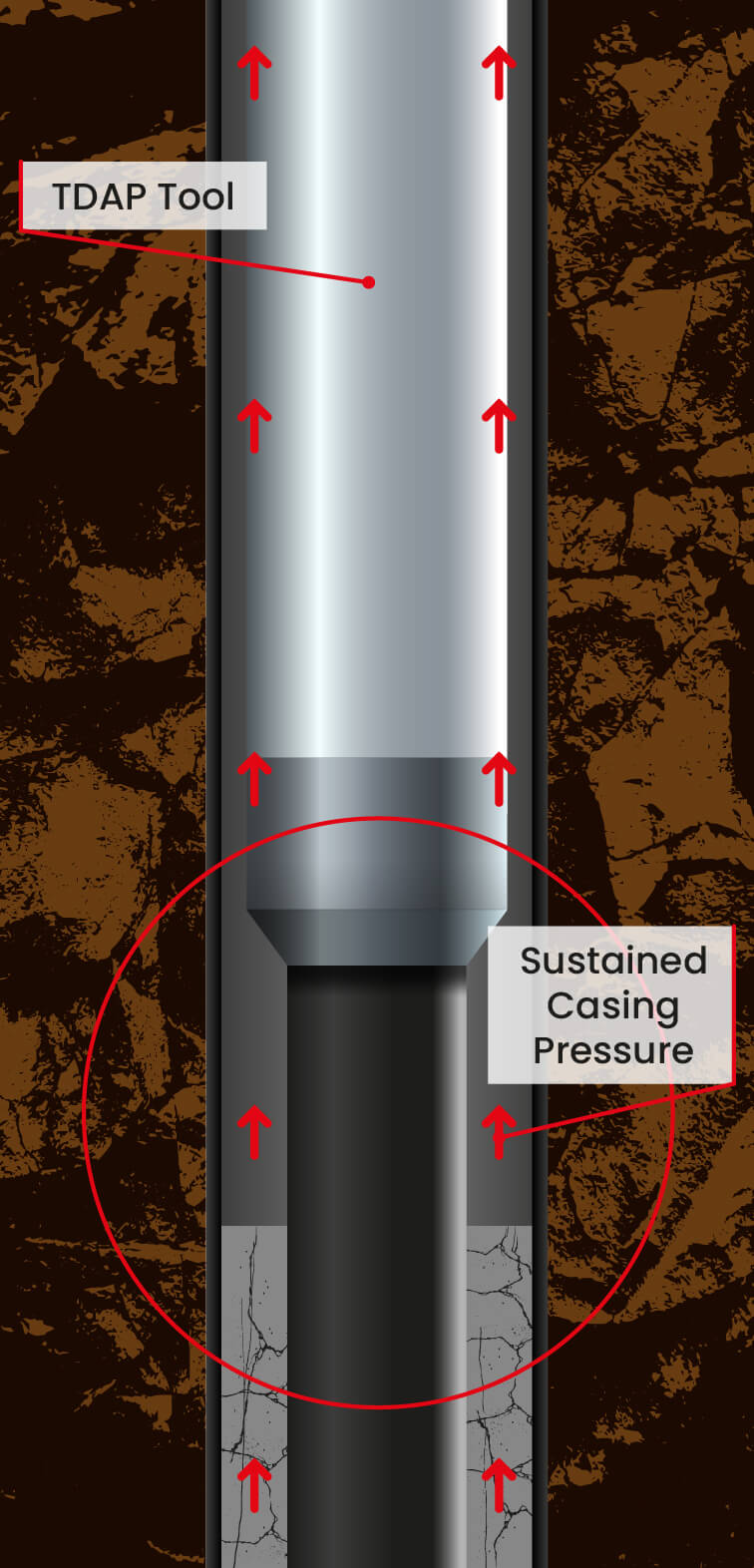

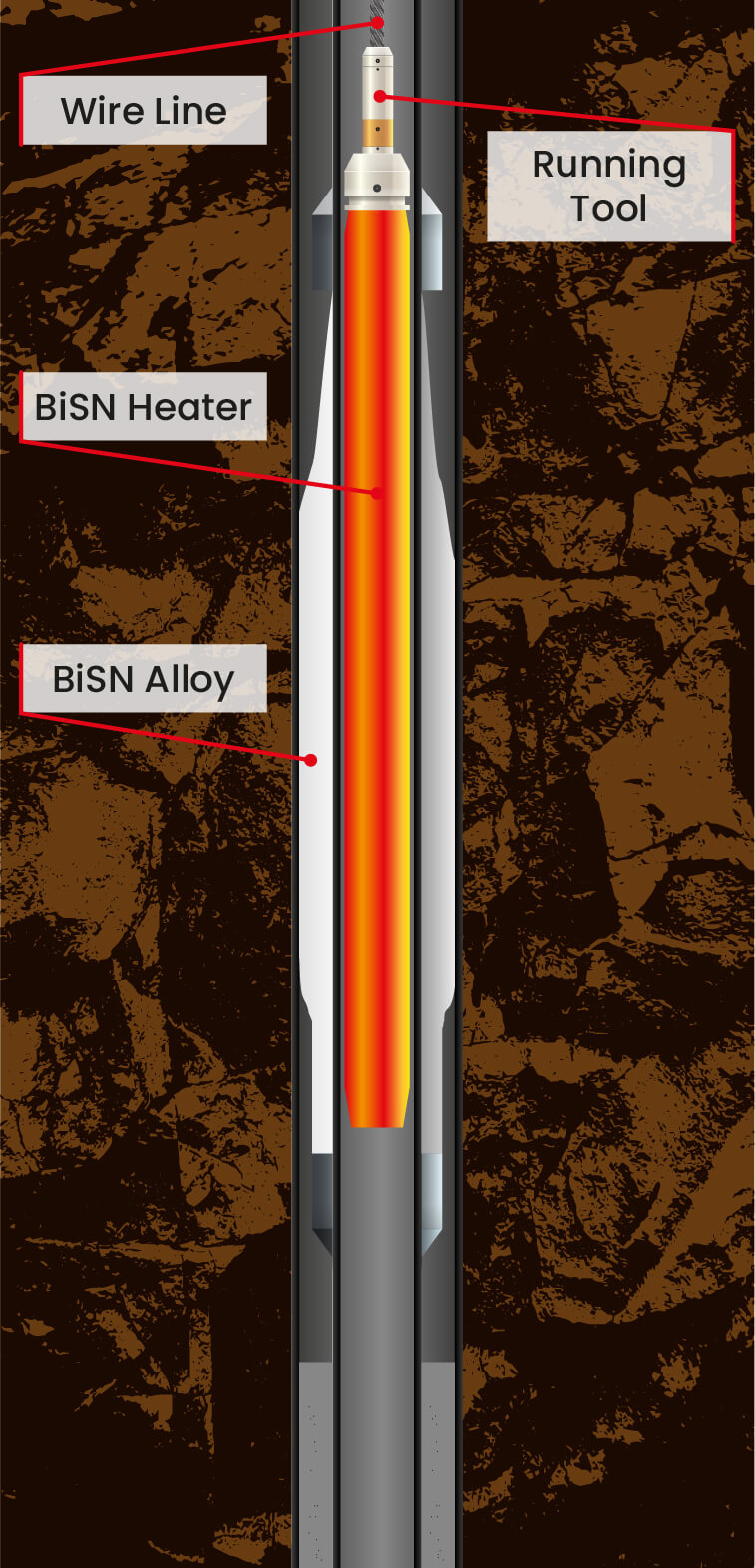

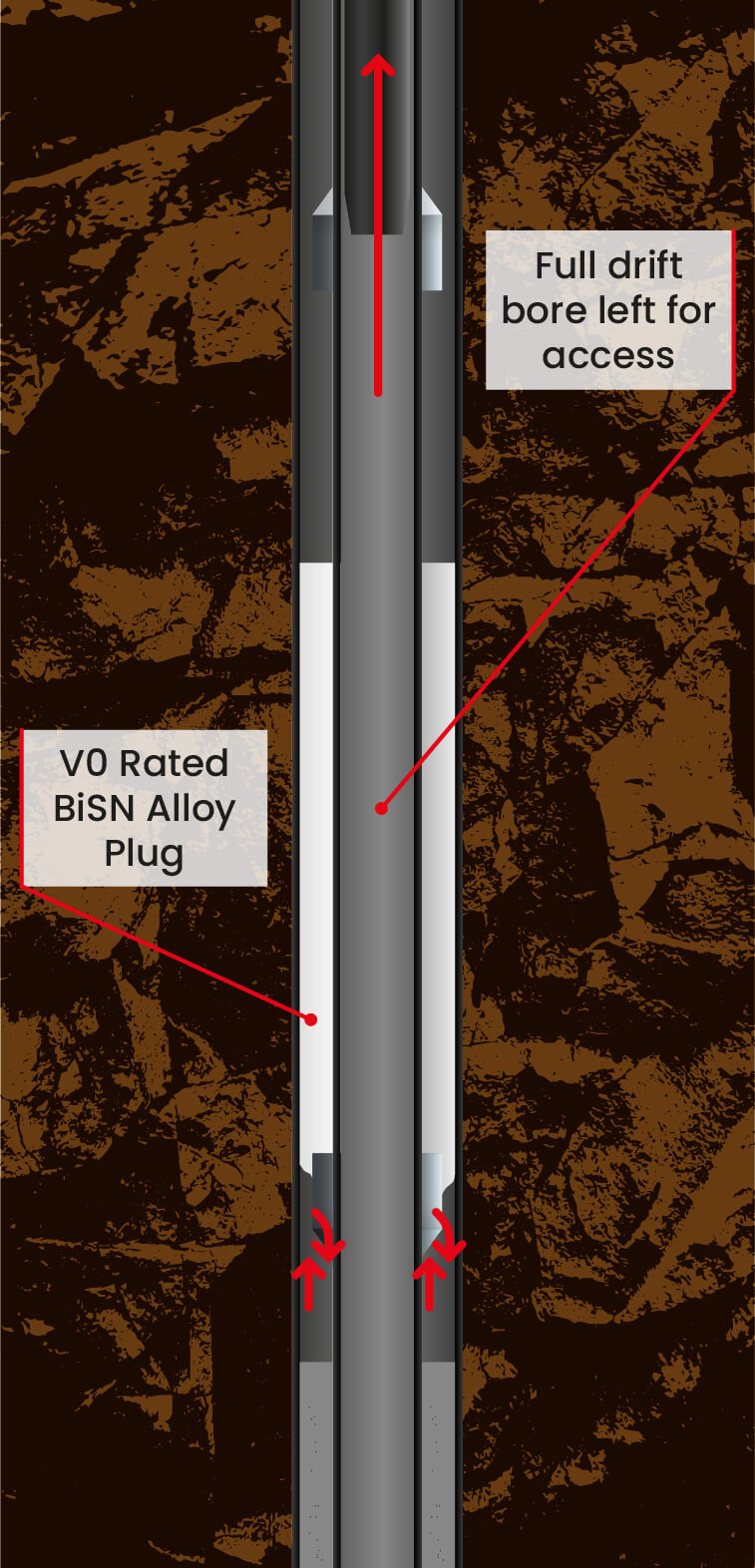

A Wel-lok™ TDAP is cast onto the outside of a full joint of 5 ½” casing and run in the well as part of the production casing string with a marker joint directly below. This joint is run to a depth above all producing zones in the area to act as the final barrier in the well if/when gas migration occurs. To ensure the bismuth alloy could seal against the open hole formation, when the casing is cemented in place the top of cement is stopped below the casing joint with the cast alloy. If Bradenhead pressure is seen at any time during the life of the well, a BiSN modified thermite heater can be run on wireline inside the casing and activated to melt the alloy and create a V0, gas tight seal in the annulus. By preplacing the alloy in the annuls, the seal can be created rigless without the need to perforate the production casing. The depth of the alloy sleeve can be found by running a CCL and locating the marker joint directly below the alloy.

A Wel-lok™ TDAP has been successfully deployed in 6 new drill wells to date with further installations ongoing. BiSN awaits the call from the operator to deploy a modified thermite heater and create a seal once Bradenhead pressure is seen.

The Wel-lok™ TDAP (Thermally Deformable Annular Packer) was developed as a preventative tool to be run as part of the original casing string. It is run on an inner casing string and the tubing cemented into place. After cementing the tubing, the TDAP™ is set by running a chemical reaction modified thermite heater inside the casing to melt the alloy and create a gas tight seal in the annulus, eliminating the possibility of future casing vent flow when the cement in the annulus ultimately degrades and develops micro-annuli. If utilised in the design of the well, this tool can eliminate future expensive interventions and unreliable cement squeezes required to address surface gas pressure through cemented annuli.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies