Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Intervention with wel-lok™ CLS (Casing Leak Seal) Tool

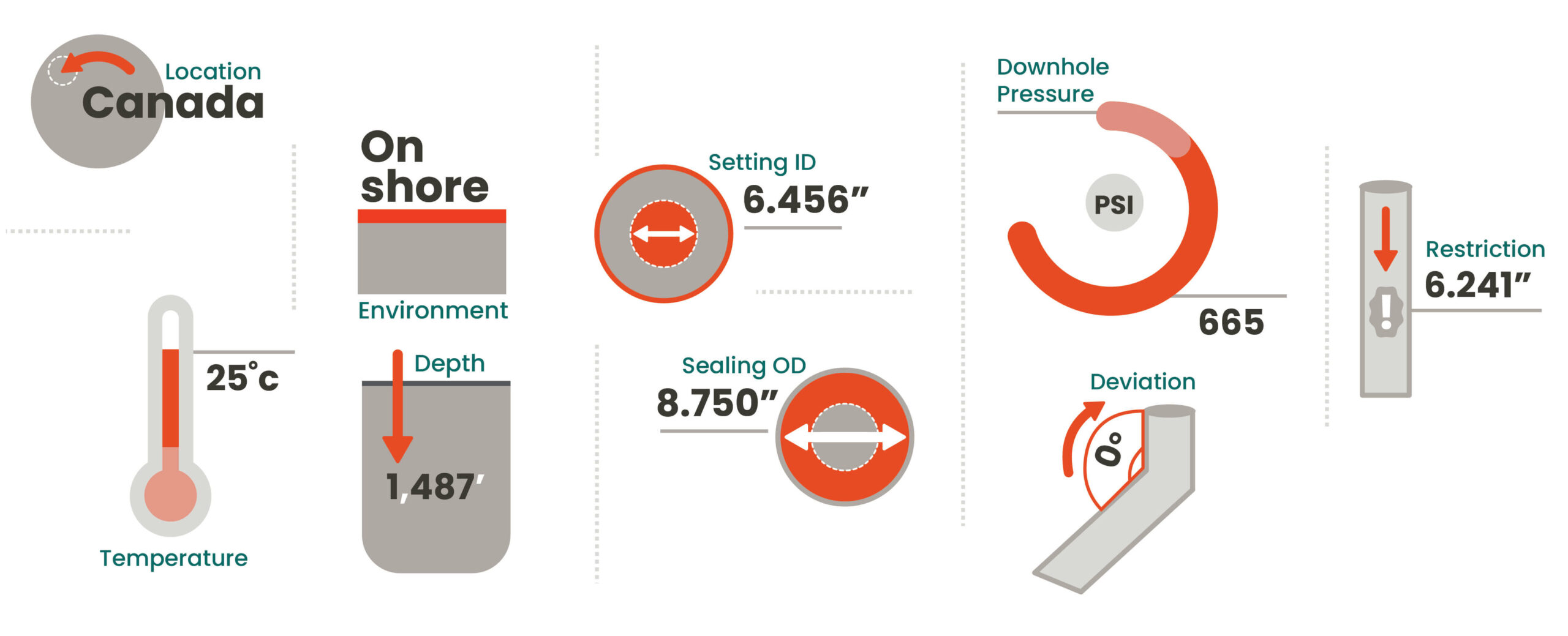

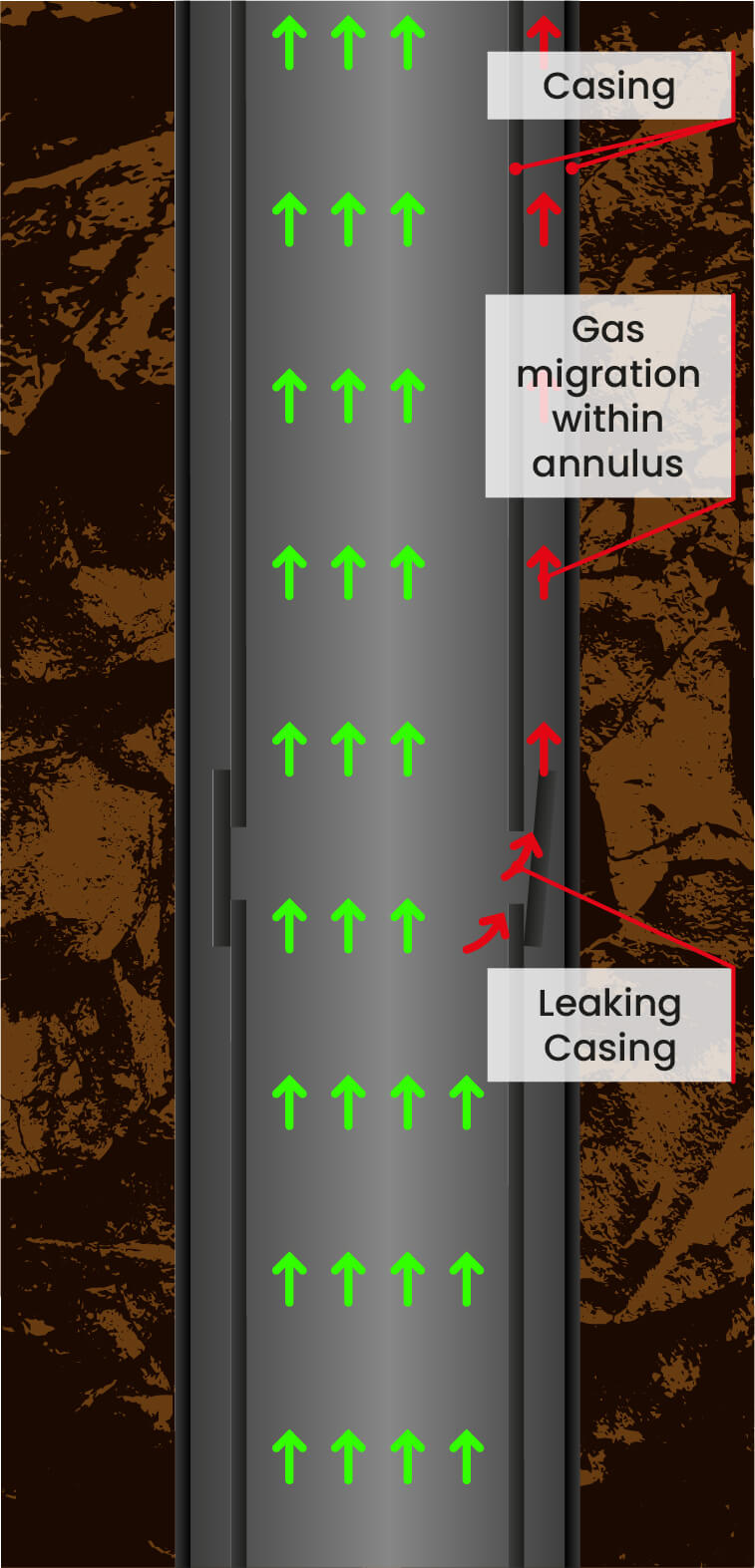

A Canadian operator had a well with a leak in the 7″ production casing. The leak zone had good cement behind the production casing but was unable to hold pressure, losing more than 250 PSI over 10 minutes.

Seal leak in situ while maintaining full drift diameter:

The customer desired a solution that would seal the casing leak without restricting drift access to zones deeper in the well. A tool was needed that could seal into the leak and then be milled to provide this full-bore access without damaging the seal.

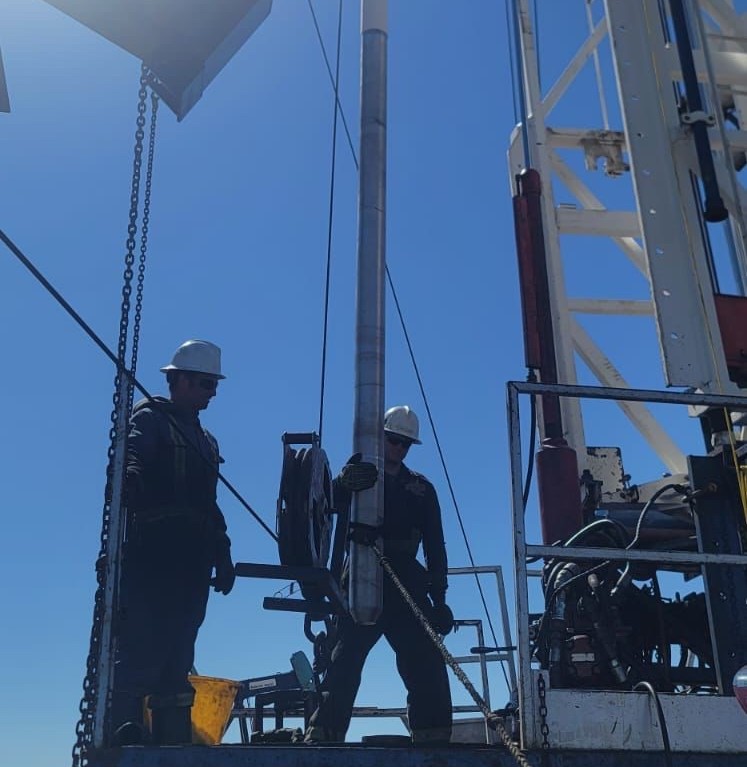

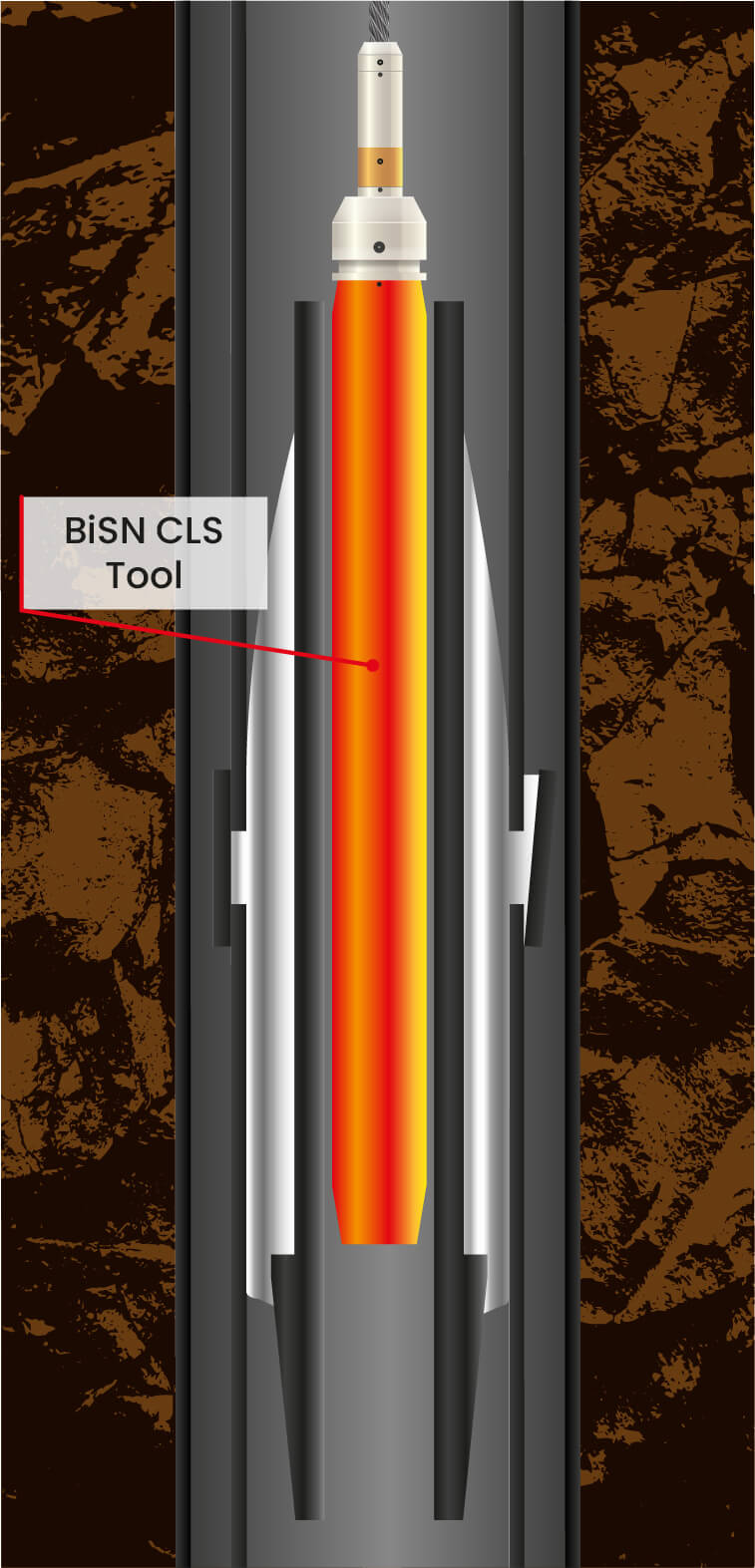

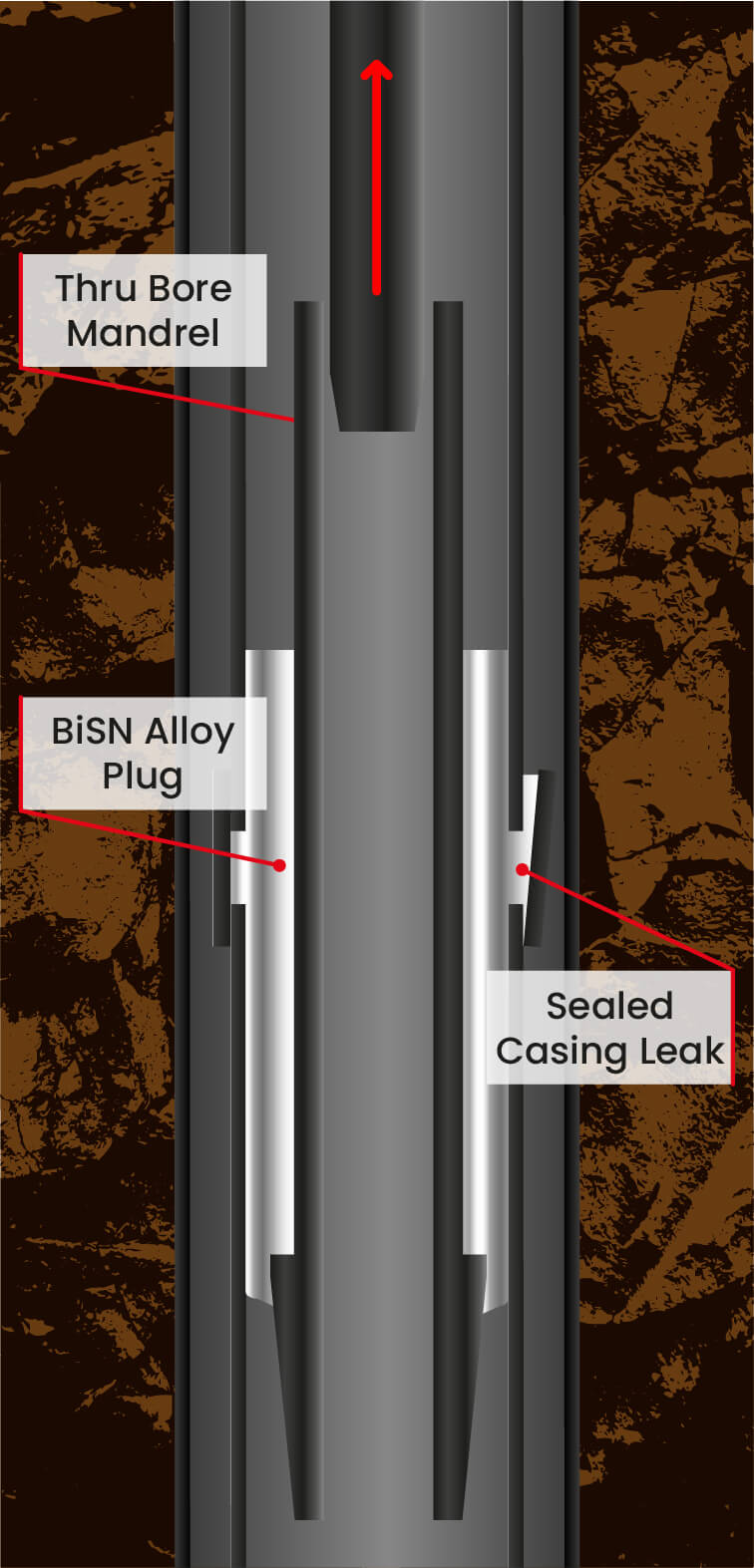

A BiSN wel-lok™ CLS (Casing Lead Seal) Tool was deployed in the well to the depth of the casing leak. The thermite heater was activated, melting the bismuth alloy. The low viscosity, liquid bismuth alloy flows like water, and was able to completely fill the leak path. While the alloy was still molten, the thermite heater was removed, leaving a solid bismuth alloy plug. The bismuth alloy then solidified, sealing off the casing leak. The thermite heater was retrieved to surface.

The operator then successfully pressure tested the plug, verifying that it was set and covering the casing leak. They then ran in hole with a mill and milled through the entirety of the bismuth alloy plug, reopening the well to full drift diameter and providing access to the deeper zones of the well. After completing the milling process, the customer performed successful 1000 PSI and 1500 PSI pressure tests, showing that the bismuth alloy had repaired the casing leak.

BiSN provided the customer with a reliable, permanent repair to the leaking production casing. This leak repair was completed in the well while still providing full drift access to the customer. BiSN was able to help the operator reduce HSE risks, operation time, and cost.

Are you looking for a cost-effective and sustainable solution for your business? Contact our technical team today.

The wel-lok™ CLS (Casing Leak Seal) was developed to address the shortcomings of traditional methods in sealing leaks in tubings and casings. This tool provides a V0 rated seal with higher pressure ratings than conventional casing patches with a larger through bore than traditional packoffs. If full bore access is required, it can be milled out leaving a seal only across the leaking area of the well.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies