Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Well Intervention with wel-lok™ PRT (Packer Repair Tool)

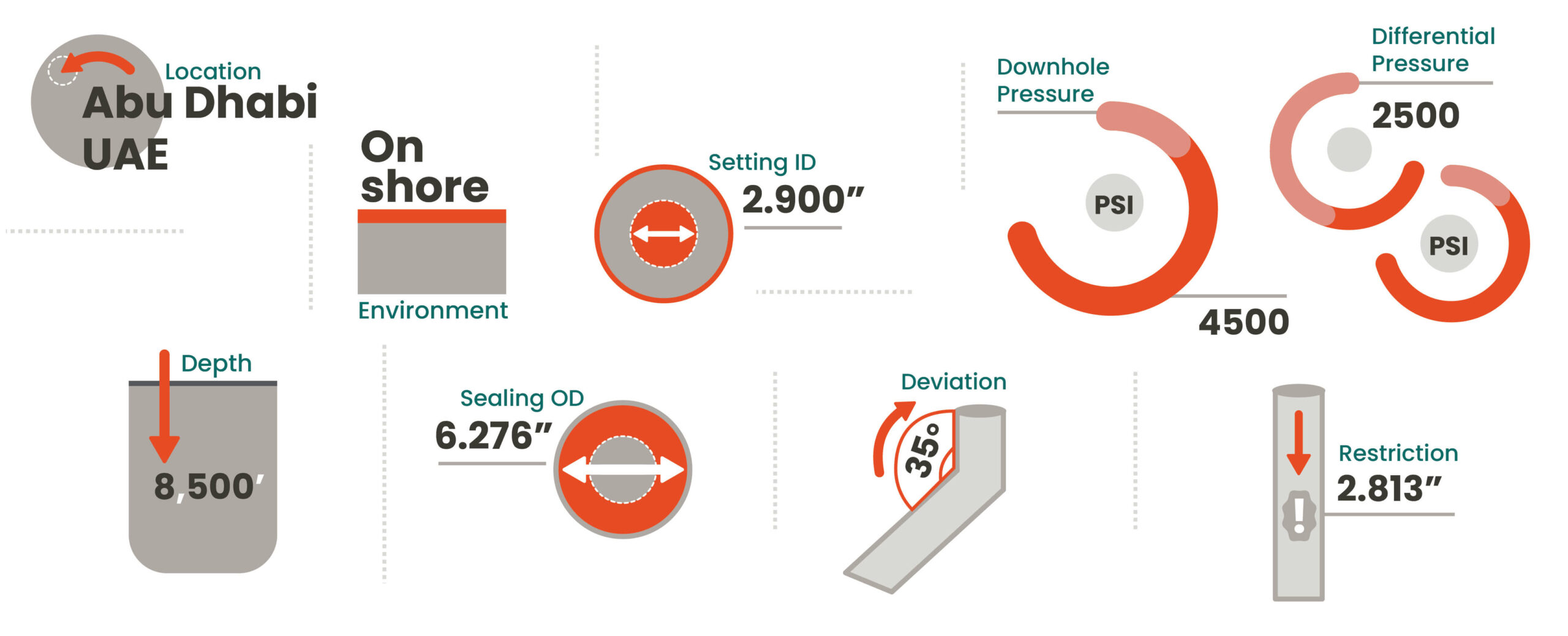

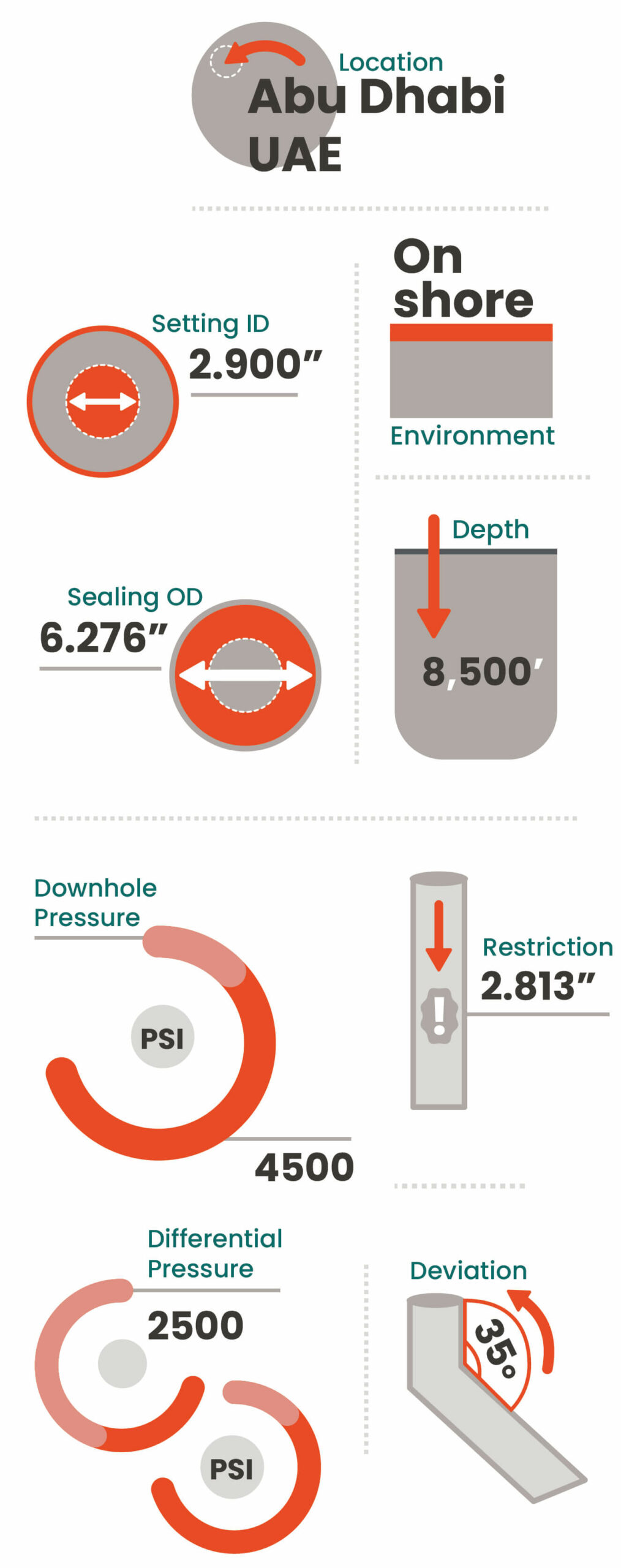

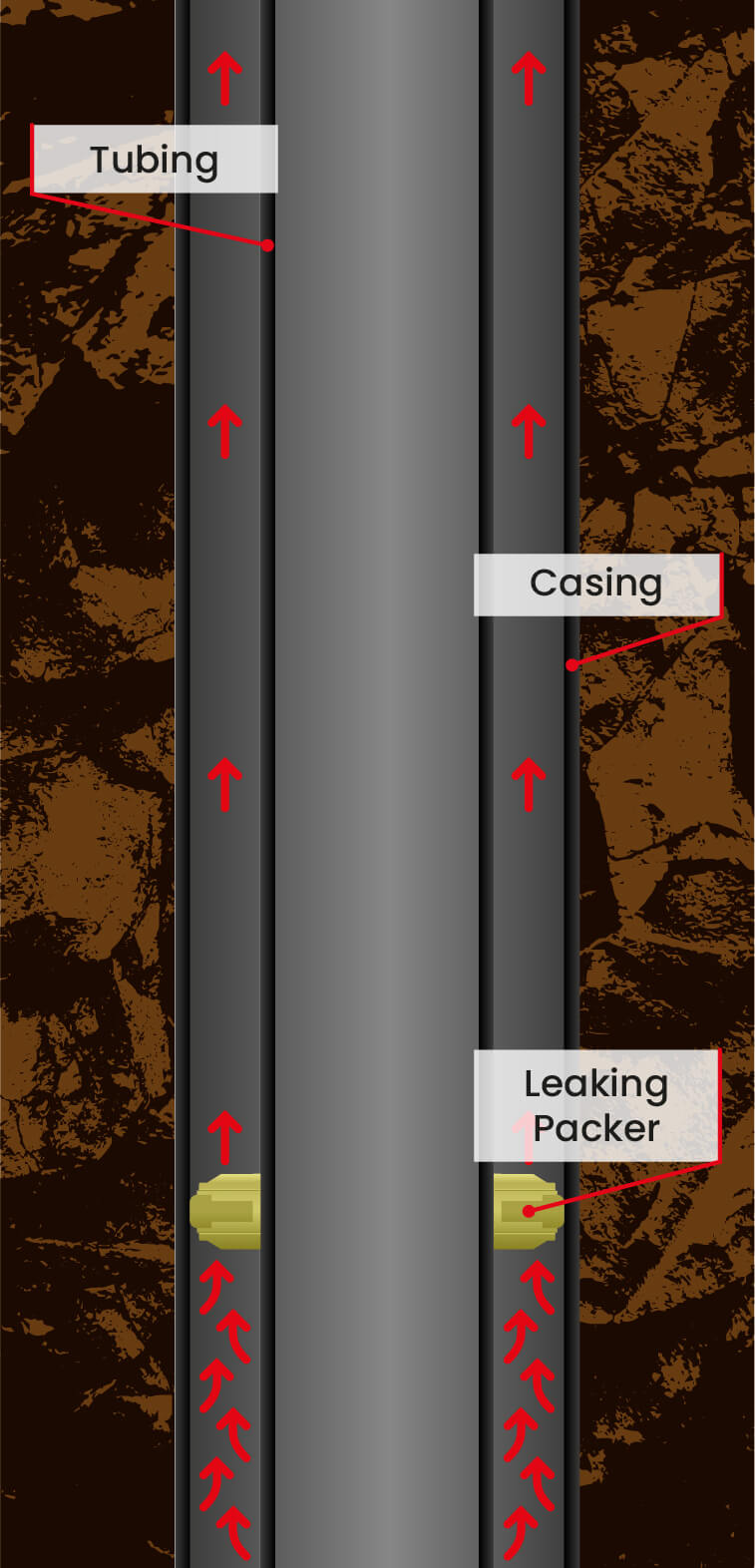

The customer had multiple water injection wells that were experiencing A-annulus pressure due to unseated production packers.

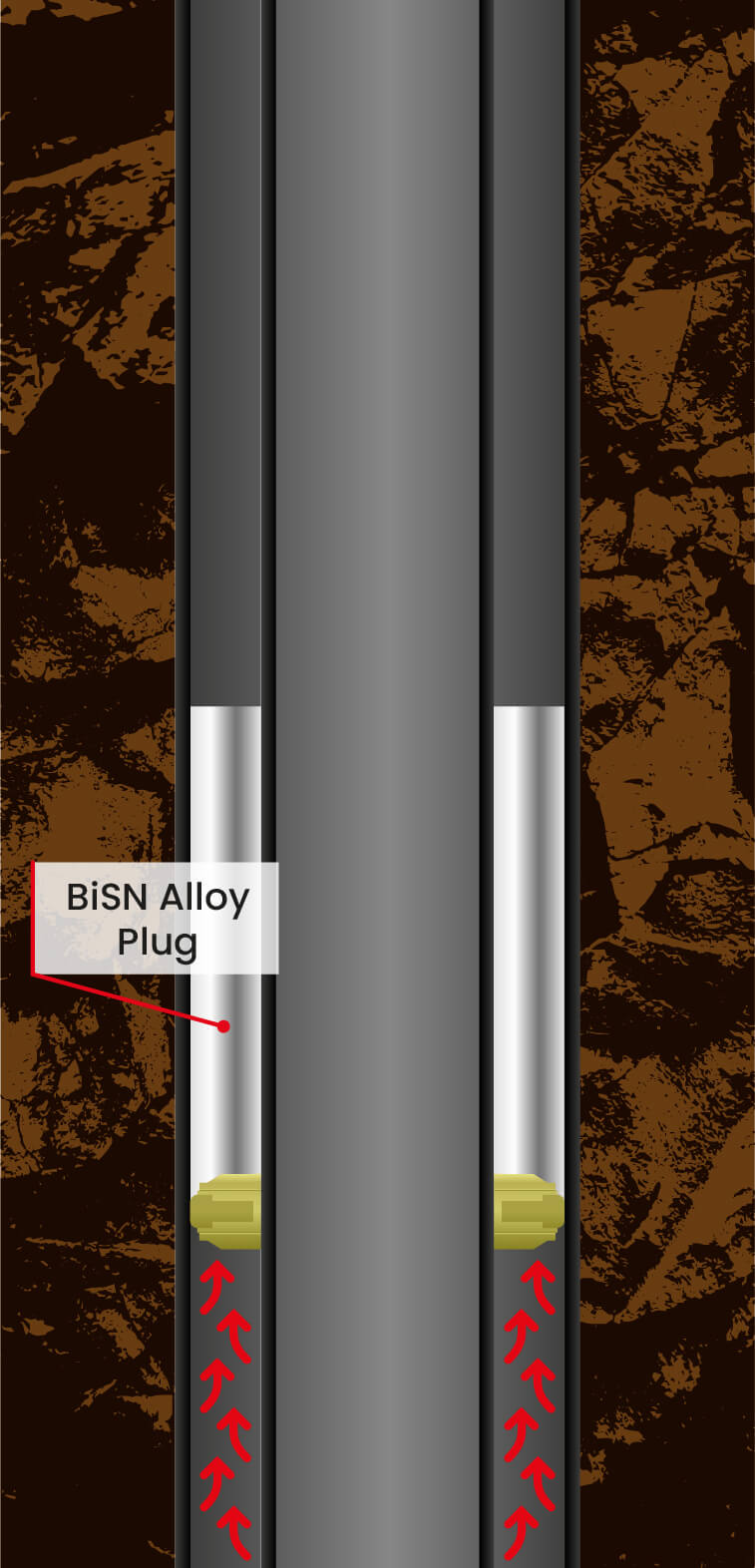

Each of these wells had 3-1/2″ tubing inside 7″ production liner / casing.

During water injection the production packers are believed to be unseating due to pressure from below the packer.

The goal was to achieve a successful seal in the annulus riglessly without creating a restriction in the tubing.

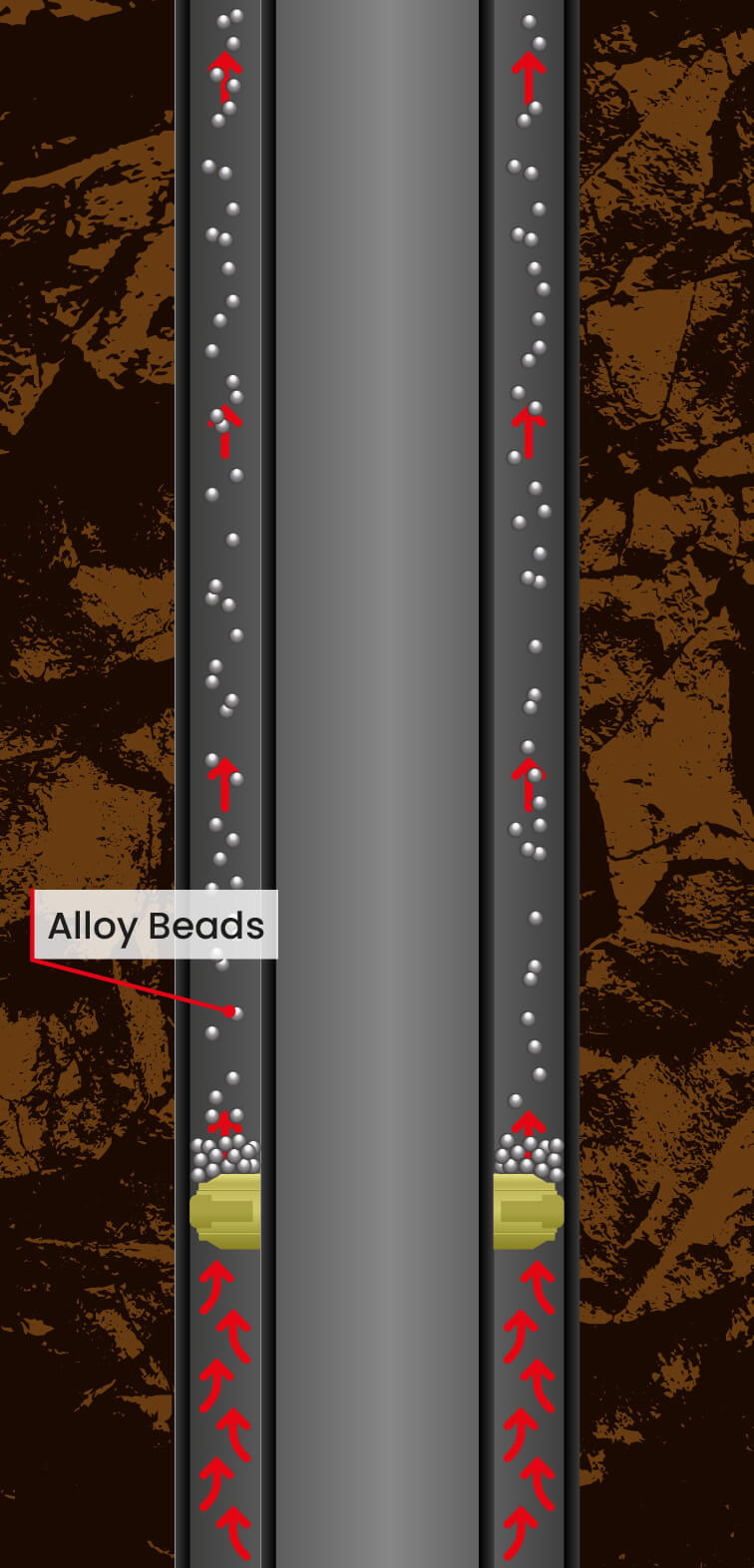

The primary objective of making a seal in the annulus without creating any restriction in the tubing meant that BiSN alloy had to be deployed directly into the annulus itself. Getting access to the annulus to introduce BiSN alloy beads at the wellhead was quite a challenge. The primary goal was to be able to melt all the alloy and create a successful seal. As opposed to traditional BiSN tools the alloy here is not in direct contact with the heater. The heater is inside the tubing while the alloy in the form of beads is in the annulus. Heat from the heater must be transferred through fluid as well as steel (tubing) to get to the alloy and start the process of melting it. The energy output of the heater had to be calibrated to not only be enough to melt the alloy but to also do so over a wide range to create a working envelop for future wells.

A simple but ingenious surface assembly was developed that could be rigged up to the wellhead to successfully introduce the BiSN beads into the annulus between the 3-1/2” tubing and the 7” casing.

A drift run was completed to the setting depth using a mock tool string to ensure that the PRT tool string could make it to the packer. A baseline CBL run was then completed to establish the annular condition prior to dropping alloy beads. The well was then killed and monitored overnight. The surface assembly was then rigged up, and desired amount of bismuth alloy dropped in the annulus.

The bismuth was allowed to settle, and a CBL run was completed to log the location of the bismuth alloy in the annulus. Once the acceptable length of bismuth alloy beads was achieved, the BiSN PRT heater was then run in the tubing on a wireline. The thermite heater was then activated and after 30 minutes, the tool string was pulled out of hole.

The annular plug was pressure tested and the well returned to injection with no pressure up the A-annulus, indicating a successfully repaired packer.

By remediating the water injection well, the operator was able to maintain a constant production level from the field therefore maintaining production targets whilst significantly reducing intervention costs and prolonged downtime.

The wel-lok™ PRT (Packer Repair Tool) is designed to repair a leaking production packer by creating a new seal in the production tubing by casing annulus. Sealing a production annulus with a PRT™ eliminates the need

to remove a production string from a well to replace the packer, reducing operator costs and downtime while introducing a superior seal in the well.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies