Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Plug and Abandonment with Wel-lok™ STC (Seal Through Casing) Tool

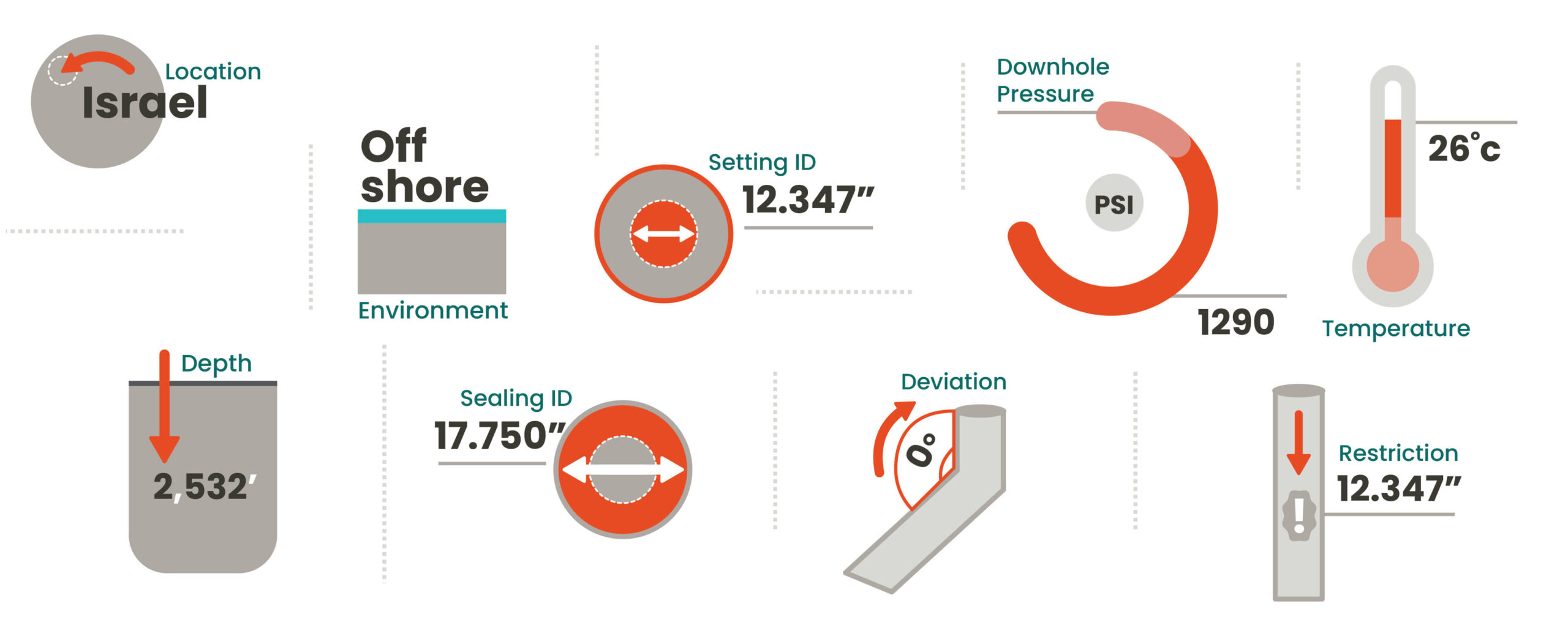

An offshore well off the coast of Israel was being abandoned.

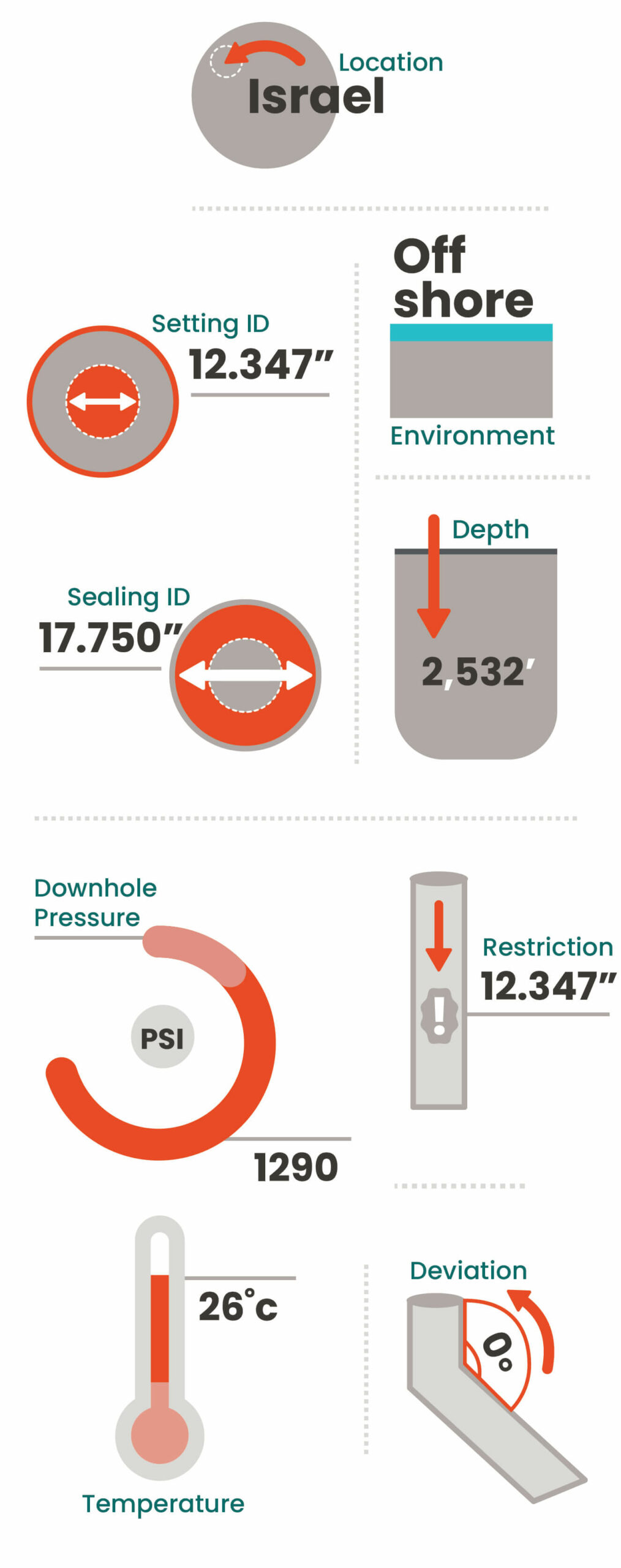

Cement had already failed in this well, with both the 9-5/8″ X 13-3/8″ and the 13-3/8″ X 20″ cemented annuli experiencing gas pressure.

The customer desired a plug that could form a gas tight seal all the way out to the 20″ casing.

High Expansion Requirements:

The tool was to be deployed through 9-5/8″ casing to form a gas-tight permanent barrier inside the 20″ casing, forming a seal more than two times the diameter of the tightest restriction.

This operation used the field-proven BiSN Wel-lok™ STC (Seal Through Casing) Tool that has been deployed successfully multiple times.

BiSN field engineers mobilized and deployed the tool in under one week. This first well of the multi-well campaign utilized an off-the-shelf BiSN solution resulting in quick turnaround times from order to successful deployment for the operator.

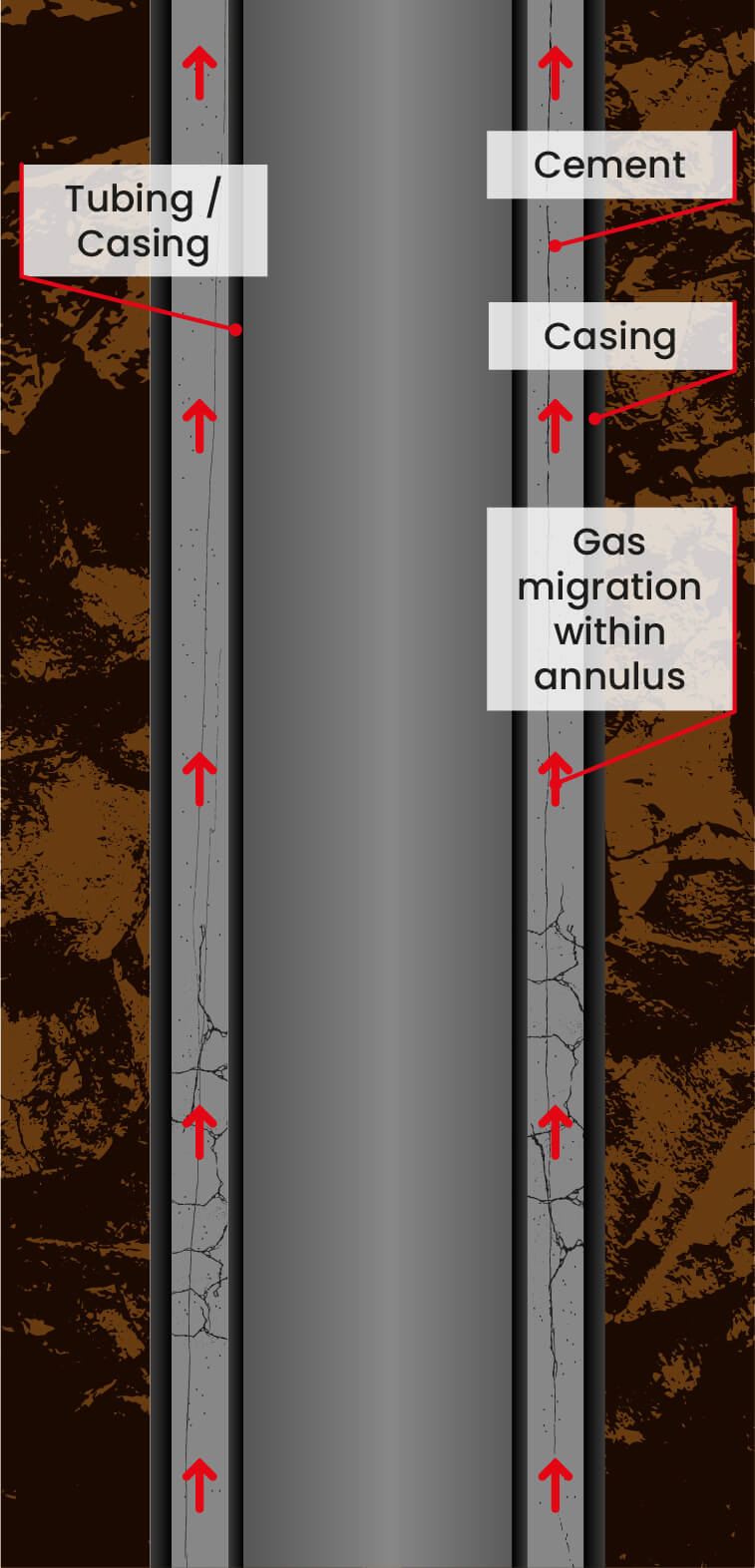

A window was section milled in both the 9-5/8″ and 13-3/8″ casings. A high expansion base was set in this window, then the BiSN chemical reaction heater was run into the well and tagged on top of the base. Bismuth alloy beads were then deployed from surface around the heater to be used for forming the seal. The thermite heater was activated via a timer running tool. Once the bismuth alloy was fully molten, the thermite heater was retrieved from the plug, allowing a solid single material barrier to form inside the 20″ casing.

The heater was then removed from the well and the molten alloy was allowed to solidify. A pressure test was performed on the plug indicating successful pressure sealing at 700 PSI differential, followed by a negative bubble test which resulted in zero bubbles.

BiSN provided the customer with a permanent barrier, more reliable seal than traditional cement.

By shortening the required section milled windows, BiSN was able to help the operator reduce HSE risks, rig time, costs and carbon footprint.

The Wel-lok™ STC (Seal Through Casing) has been developed to achieve a gas tight V0 seal well annuli that cannot be achieved by traditional cement balance plugs. Run on electric line, this tool does not need surface pumping equipment to circulate the alloy in place. Due to its viscosity and density, once melted the liquid alloy will flow with gravity into the annulus. When it cools below its melting point it solidifies, expands and creates a gas tight seal across the entire wellbore. The entire process, from melting to solidification, takes place in minutes and the seal is ready to test within an hour.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies