Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Plug and Abandonment with Wel-lok™ TS (Tubing Seal) Tool

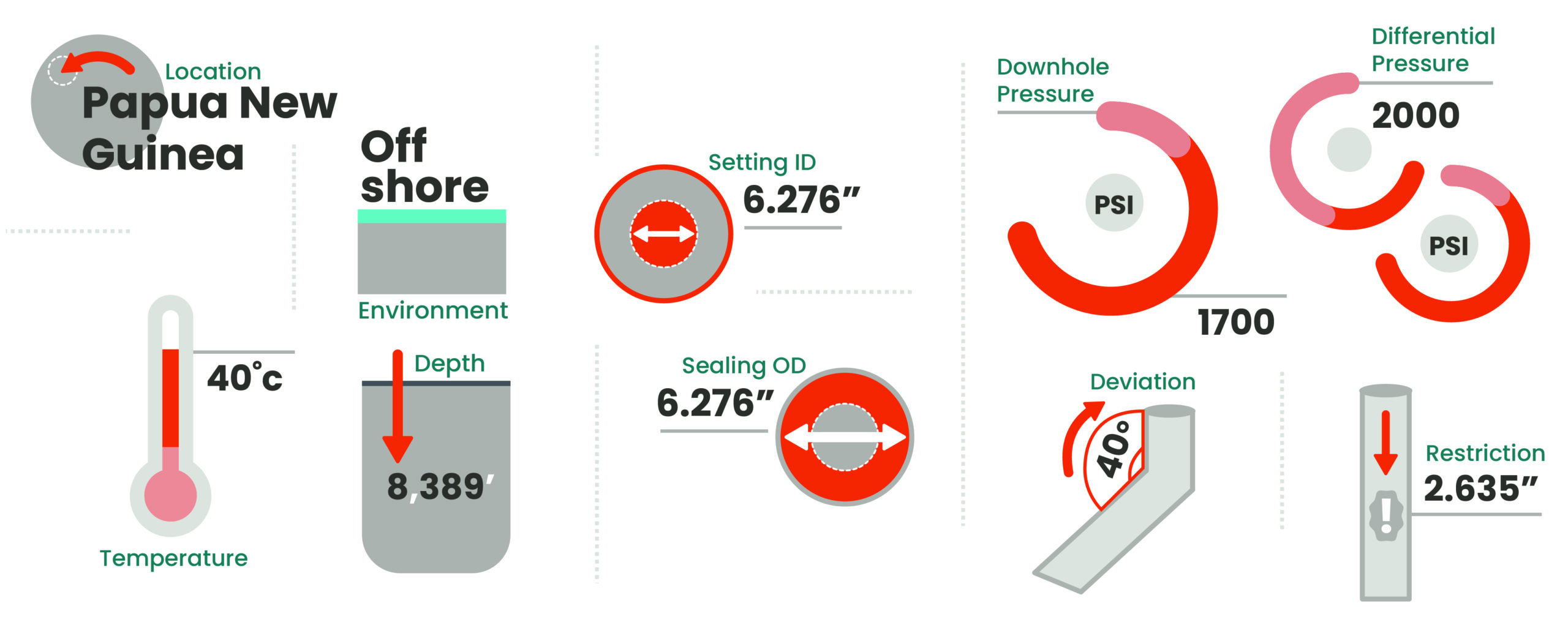

An onshore well in Papua New Guinea was being permanently abandoned.

A cement plug was previously set in the well without success. The well would not hold a column of fluid without significant losses. The customer turned to BiSN to repair the cement plug using a high expansion bismuth alloy seal.

High Expansion Requirements:

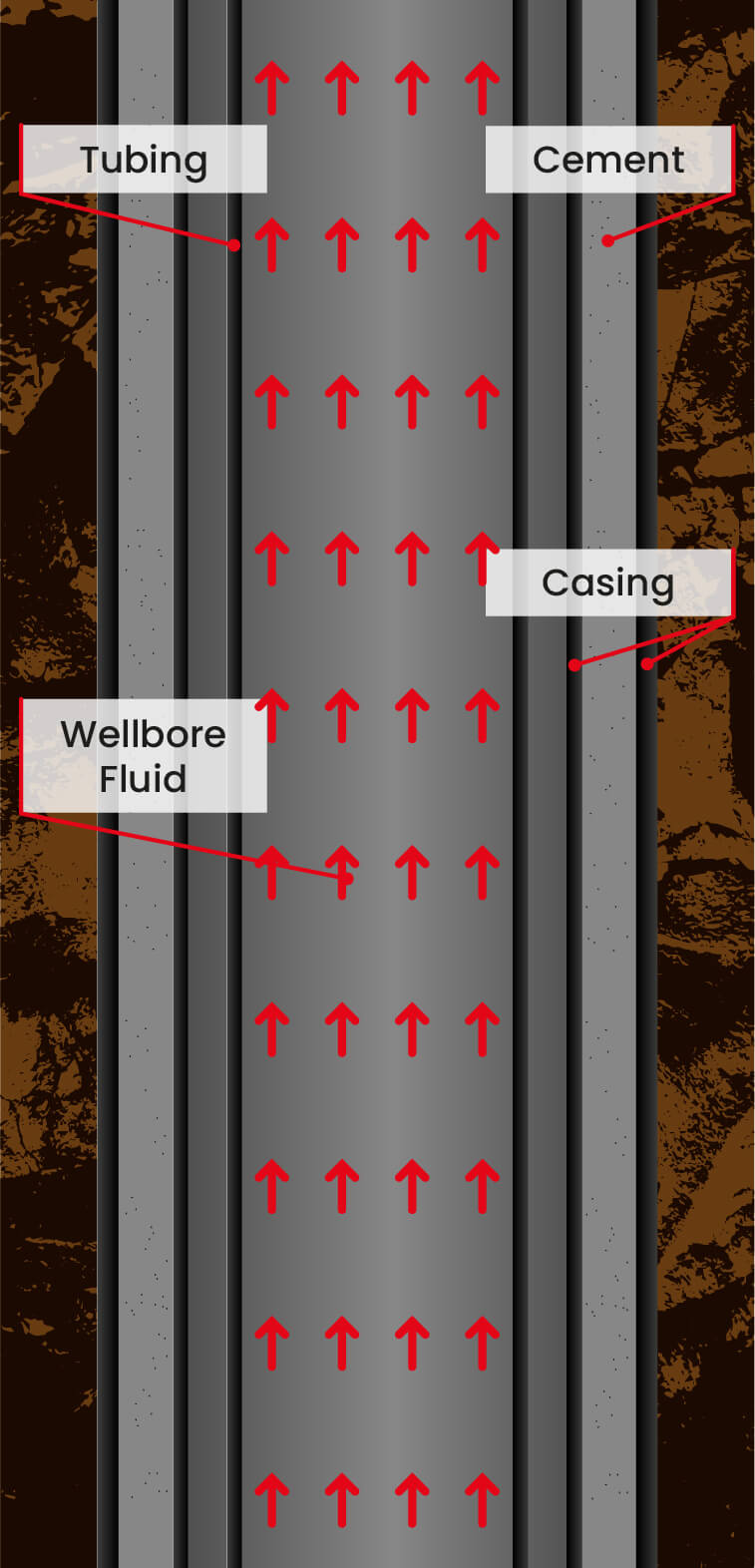

With a 2.635″ restriction we needed to create a 2.5″ OD tool to create a permanent seal inside a 6.276″ ID where a cement plug had previously failed. To complete this high expansion job, bismuth alloy shot was pumped from surface – the first for a Tubing Seal deployment by BiSN.

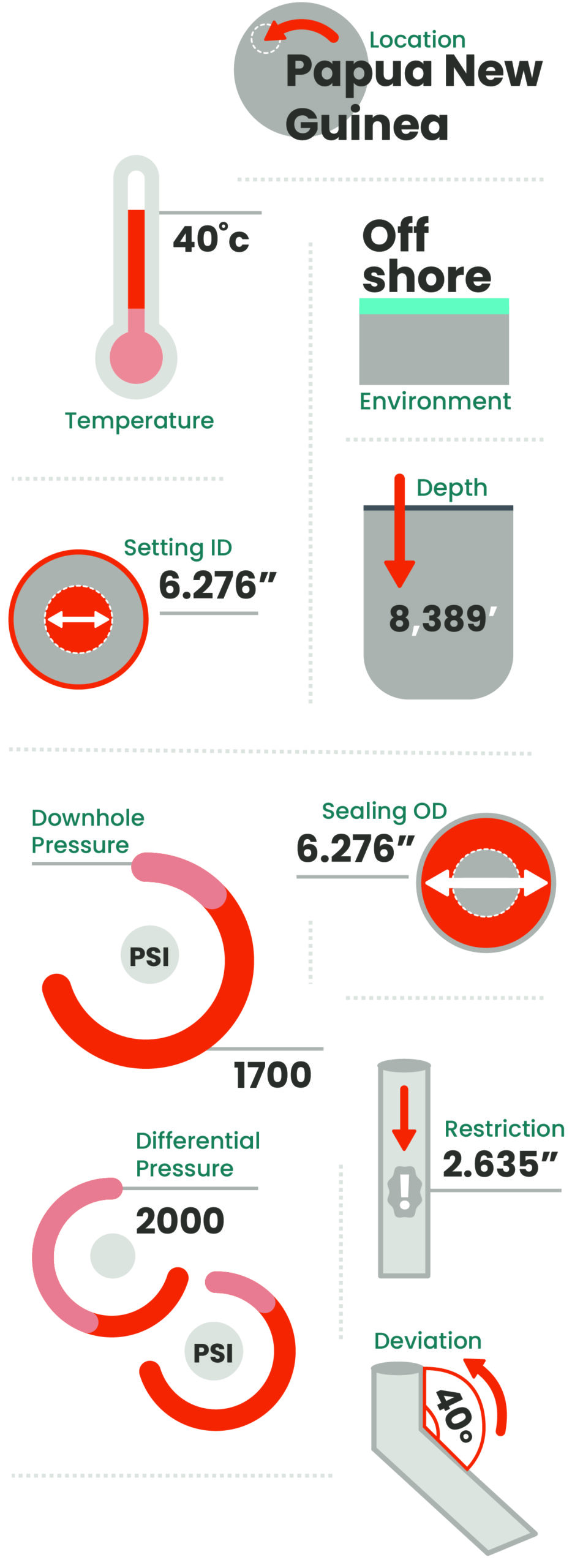

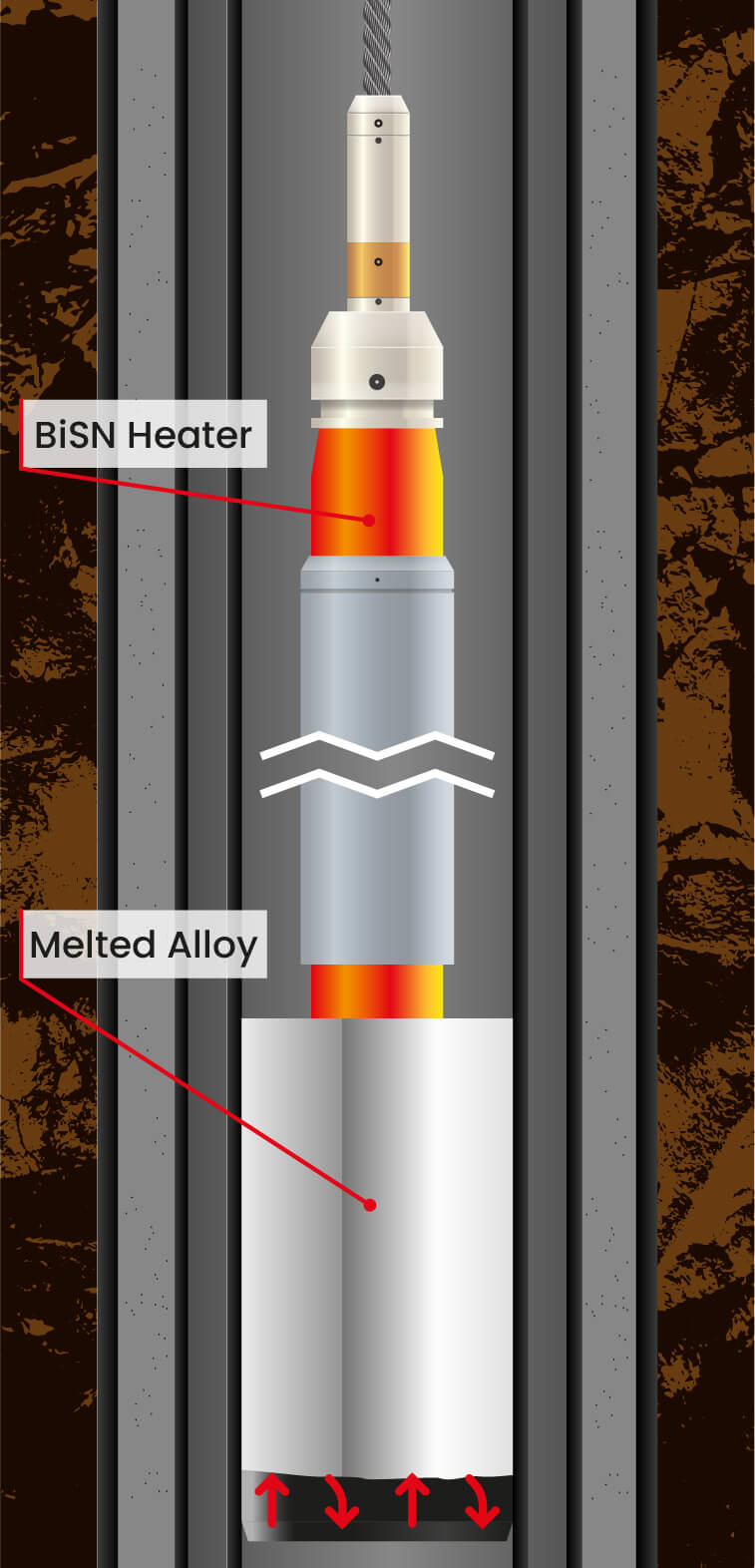

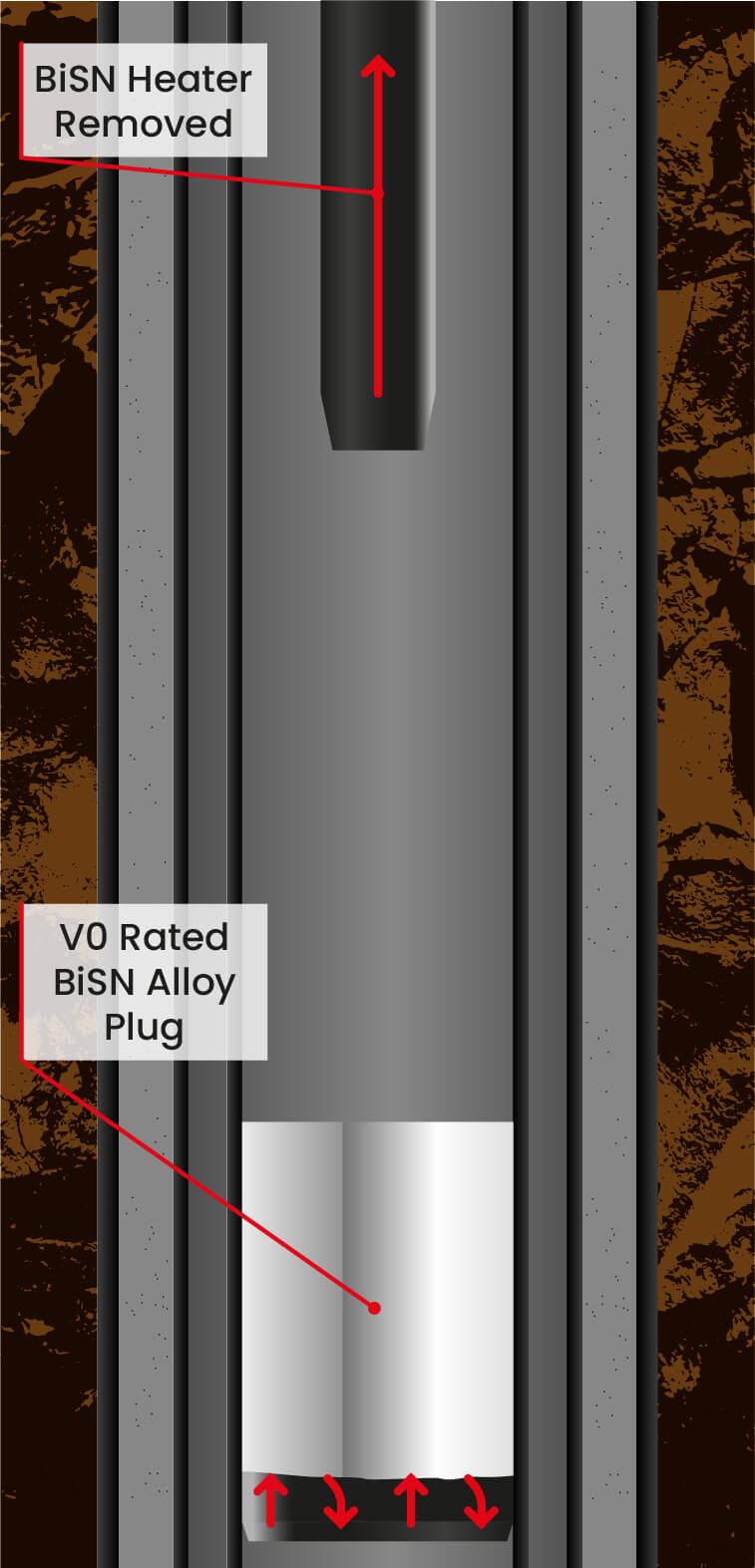

A BiSN Wel-lok™ TS (Tubing Seal) Tool was set on top of a failed cement plug to create a seal inside the tubing. A 2.5″ OD thermite heater was run to the top of the cement plug. Bismuth alloy beads were pumped down the tubing until they settled around the thermite heater. The heater was activated, melting the bismuth alloy and forming a seal in the tubing. The alloy was allowed to solidify, and the plug was tested via wireline overpull, indicating a successful plug setting.

A pressure test was then performed on the well to test the integrity of the bismuth alloy plugs. Prior to the setting of the BiSN plugs, pressure tests were failing prior to building up any pressure. After setting the BiSN plugs, a pressure test of 500 PSI was successfully completed, allowing the operator to finish the abandonment of the well.

BiSN provided the customer with reliable, permanent replacements to traditional seals that had already failed to create a seal. By deploying these tools via e-line, BiSN was able to help the operator reduce HSE risks, operation time, and cost.

Are you looking for a cost-effective and sustainable solution for your business? Contact our technical team today.

The Wel-lok™ TS (Tubing Seal) was developed to overcome the shortcomings of traditional methods, using bridge plugs and cement during well abandonment. It is typically run on electric line but can be deployed on a slick line or coil tubing as well. It can pass through small restrictions such as damaged or crushed tubing, yet still create the gas tight seal. It has a higher expansion ratio than conventional plugs, higher pressure ratings than inflatable packers and gas blocking abilities that cement cannot match.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies