Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

BiSN provided a gas-tight solution solution for the operator.

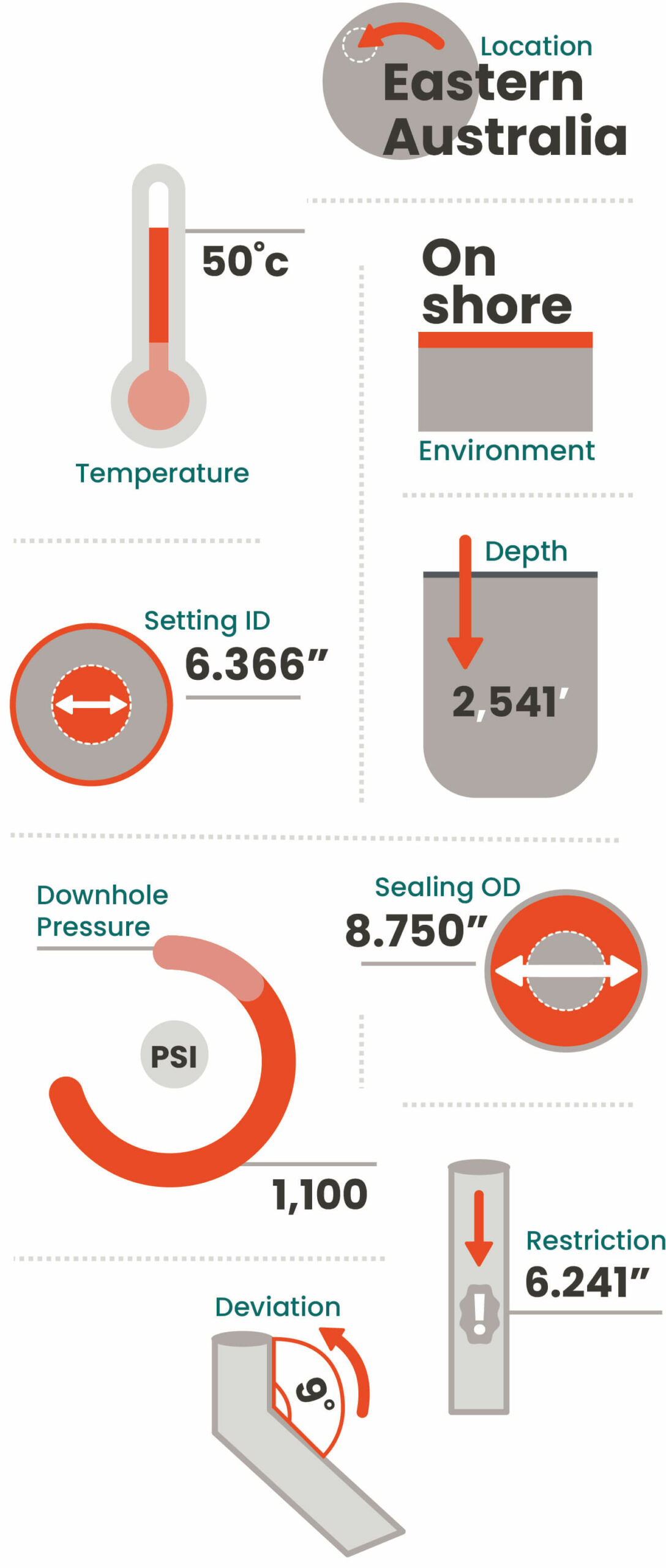

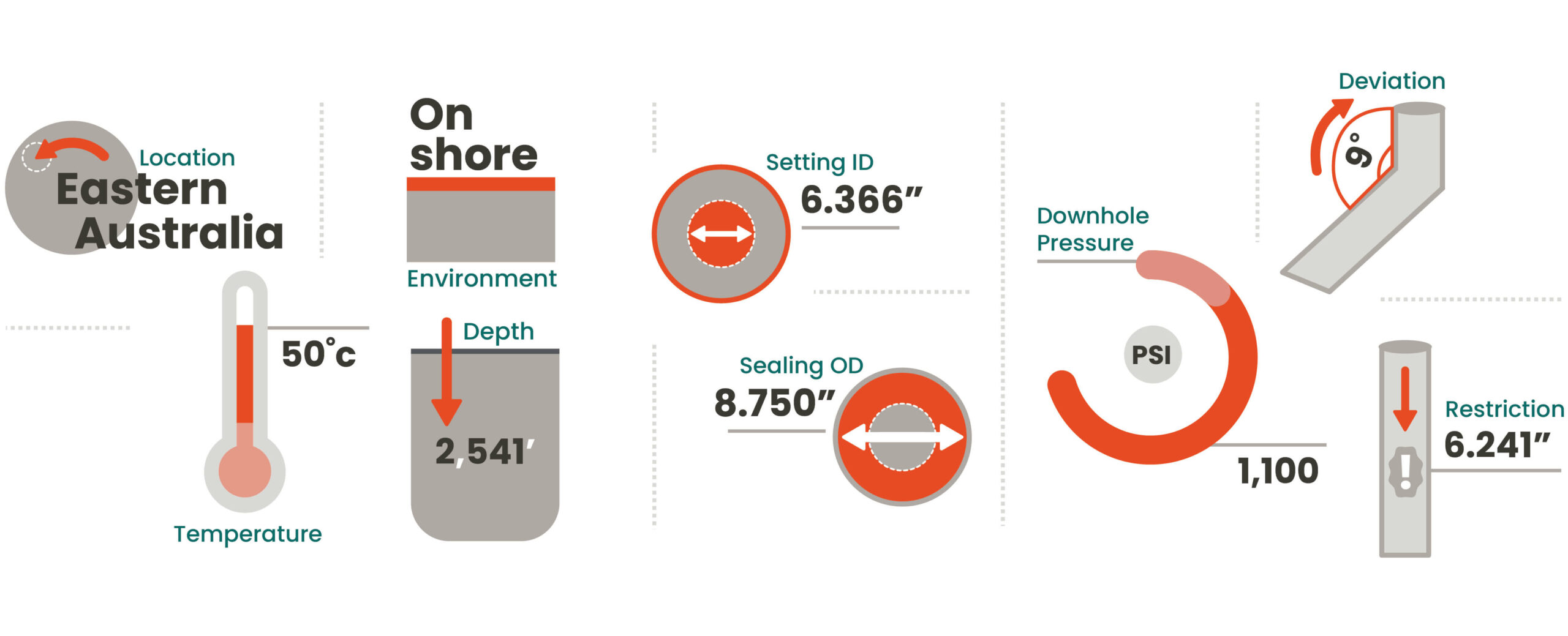

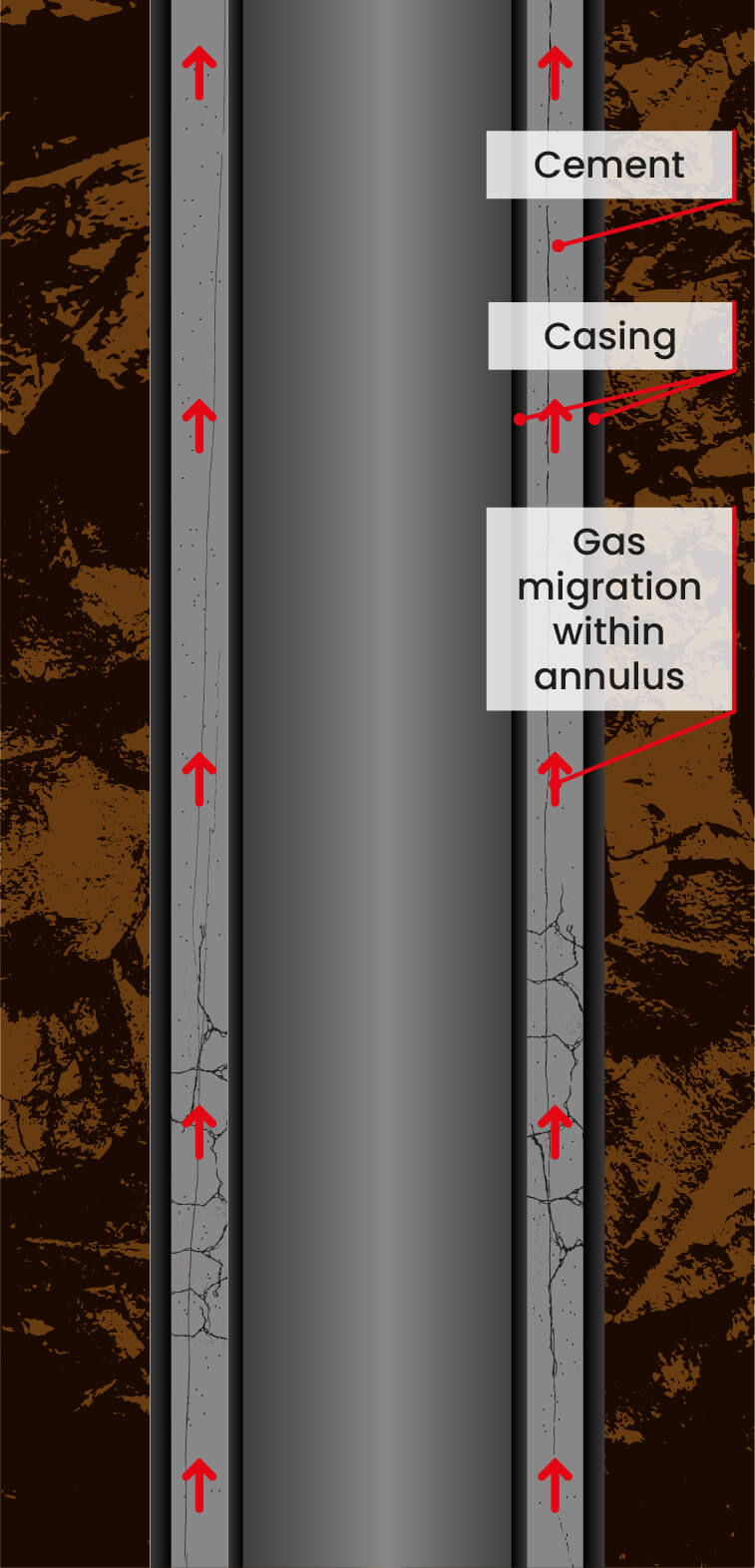

Recently a gas company located in the Surat Basin deployed the BiSN wel-lok™ Cement Repair Tool (CRT) in zonal isolation applications where the cement was known to have failed over time and isolation was critical for well operation. A permanent repair was needed that could be deployed in the 7” x 9.625” annulus through perforations. BiSN was contacted to provide a gas-tight solution that would reliably repair the cement in the annulus.

The client had multiple potential gas sources below the aquifer that needed to be isolated. Having attempted conventional approaches in similar situations unsuccessfully previously the client was happy to see the wel-lok™ CRT system succeed and facilitate recovery of 3 key wells. BiSN provided a solution that could be set in a short zone, with plug lengths of approximately 3m. This allowed for multiple zones to be isolated quickly.

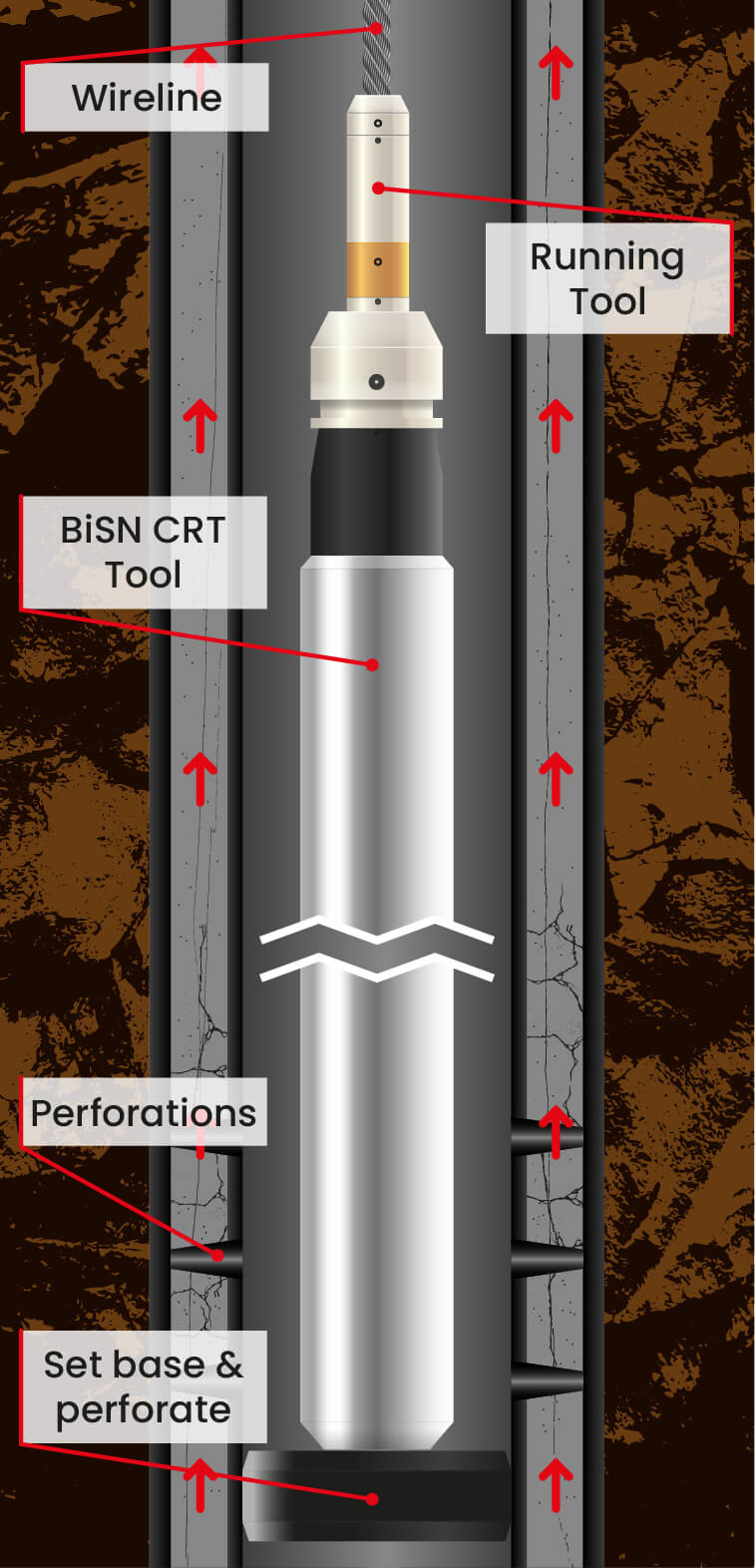

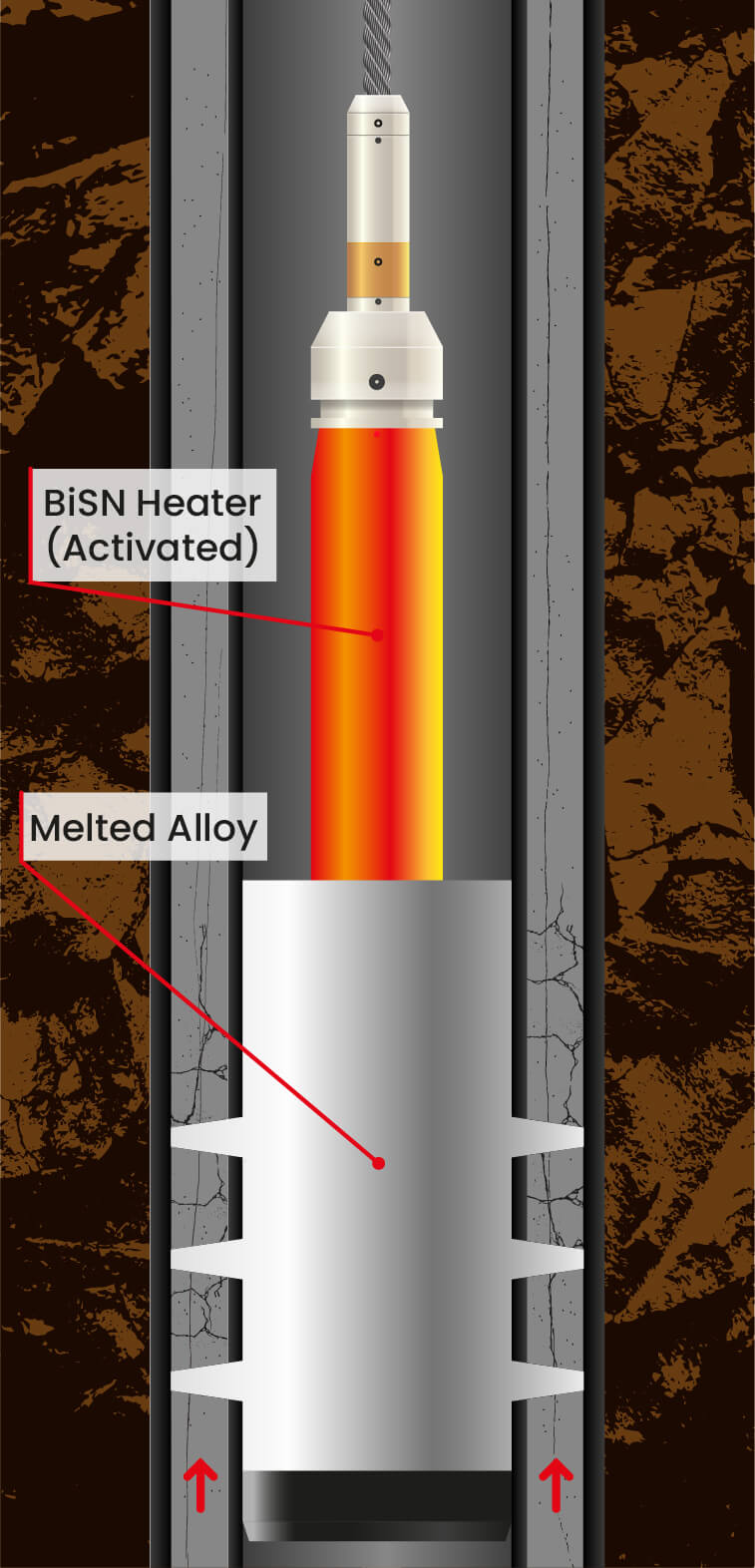

BiSN produced a Wel-Lok™ Cement Repair Tool designed to deploy alloy through perforations into broken annular cement. Prior to deployment, the selected zone above the gas source was perforated to provide annular access and break up the leaking cement. The BiSN Cement Repair Tool was then run to depth and activated using a timer activation system.

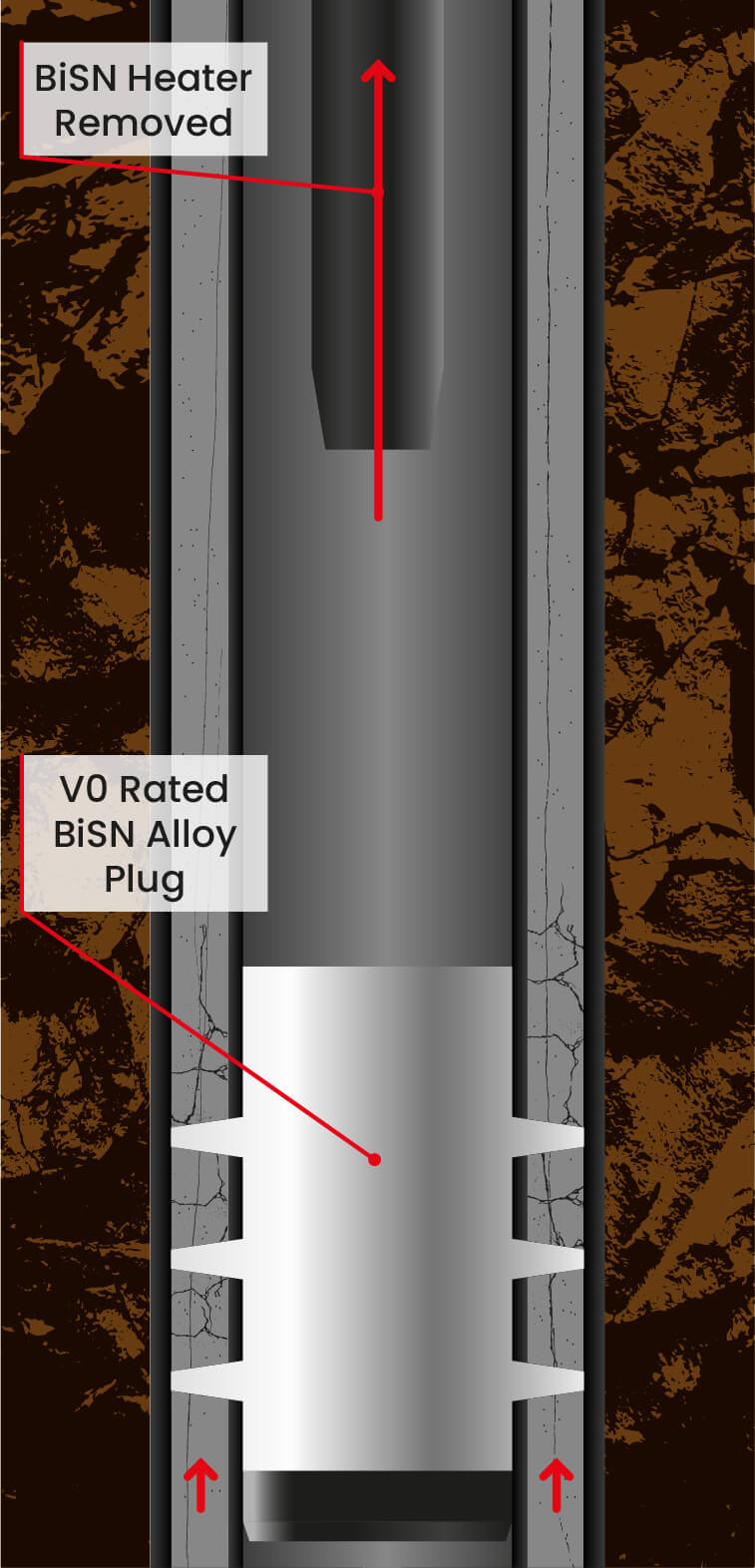

The molten alloy flowed through the perforations and filled the microannuli in the cement. The thermite heater was removed from the molten alloy, leaving a solid bismuth alloy plug. Once the alloy had solidified, a 2000 PSI, 20-minute pressure test was successfully conducted. This process was then repeated at a higher zone to isolate a second potential gas source.

BiSN’s wel-lok™ Cement Repair Tool (CRT) was successfully deployed through perforations demonstrated by successfully passing a 2000 PSI pressure test.

BiSN provided the client with a reliable solution for repairing annular cement. This eliminated the high-risk nature of cement squeezes which frequently fail while providing the long-term reliability of bismuth alloy. By reducing intervention time, BiSN was able to help the operator reduce HSE risks, total operation time, and cost.

The client also noted that BISN’s, up front planning was key to ensuring the right tool and well candidates are selected, and execution went as planned.

The wel-lok™ CRT (Cement Repair Tool) was developed to eliminate sustained casing pressure, or casing vent flow, in cemented annuli. Unlike traditional methods of perf and squeeze or perf and wash, this tool does not require any surface pumping pressure to squeeze or circulate the sealing material into place. The tool is also run rigless on electric line, sealing through casing perforations, so section milling is not required. The bismuth-based alloy has no porosity and solidifies to create a seal in minutes as opposed to hours with traditional cement and resins, eliminating the possibility of a micro-annulus being formed to allow future gas migration. If full bore access is required, it can be milled out and still maintain a gas tight seal in the annulus.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies