Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

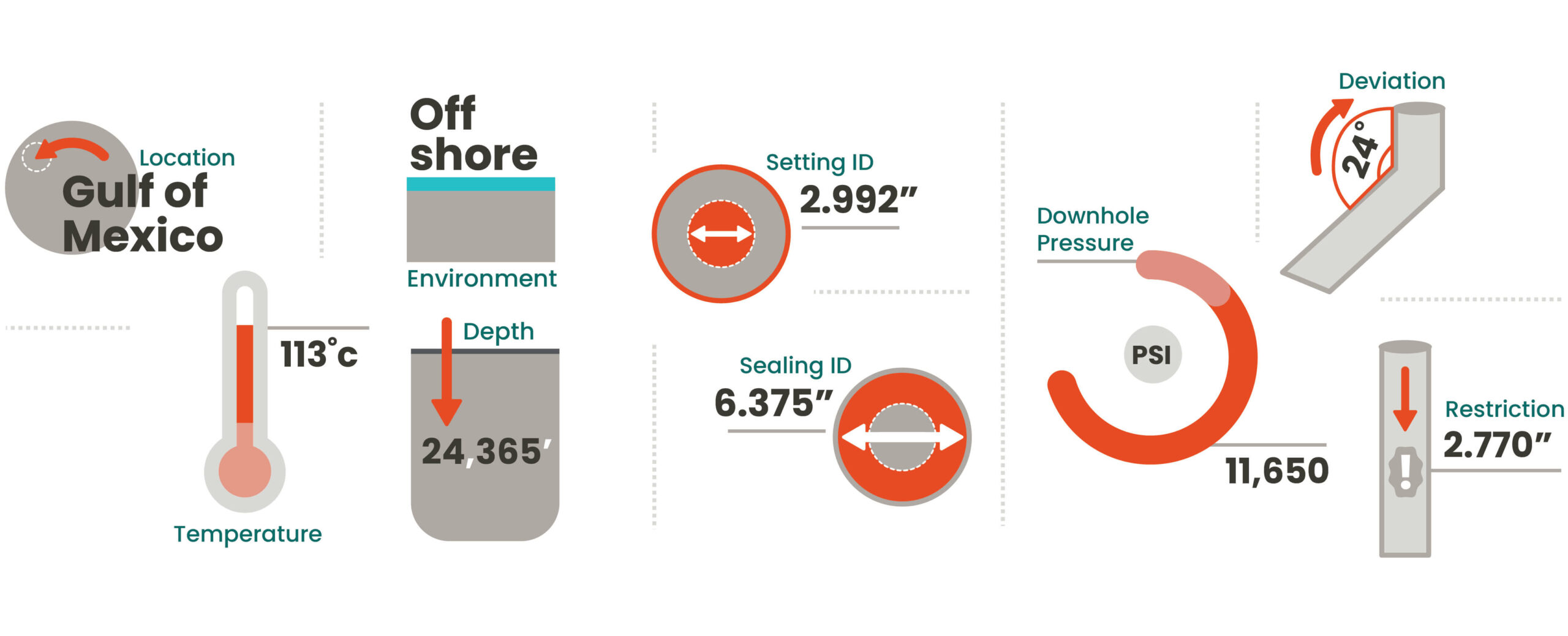

A recently completed high pressure/high temperature well in the Gulf of Mexico, was brought on production but held back to low drawdown due to sand control integrity concern and remained shut in.

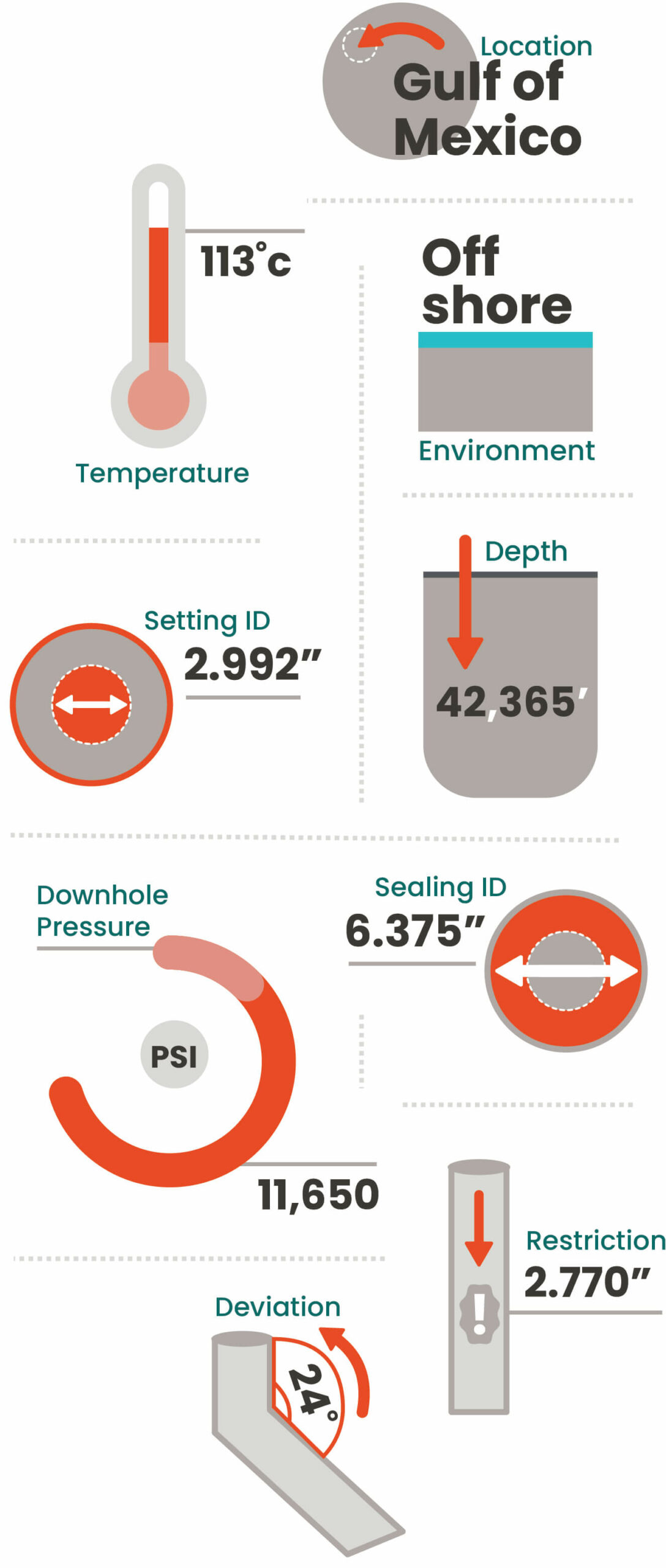

Traditional sealing technologies although capable of isolating flow inside the base pipe of the sand screen is not able to isolate the annulus. Three further attempts were made with such tools to establish solids (sand) free rate – all were unsuccessful.

BiSN’s Wel-lok™ SCT (Sand Control Tool) provides a novel solution to seal off the annulus behind the sand screen by flowing molten bismuth alloy through the sand screen and gravel pack thereby completely sealing off any flow of solids (sand) from zones below.

We helped bring the well back into production and increased production.

Unwanted solid (sand) production can really cripple producing wells and cause them to be shut in – as demonstrated in this case. The biggest challenge is to gain access to the annulus behind the gravel pack screen without any need to damage the screen already in place and achieve all this using rigless deployment without the need of any special surface equipment.

Traditional sealing technologies are either unable to seal the annulus behind the screen or rely heavily on surface pumping equipment to achieve such results.

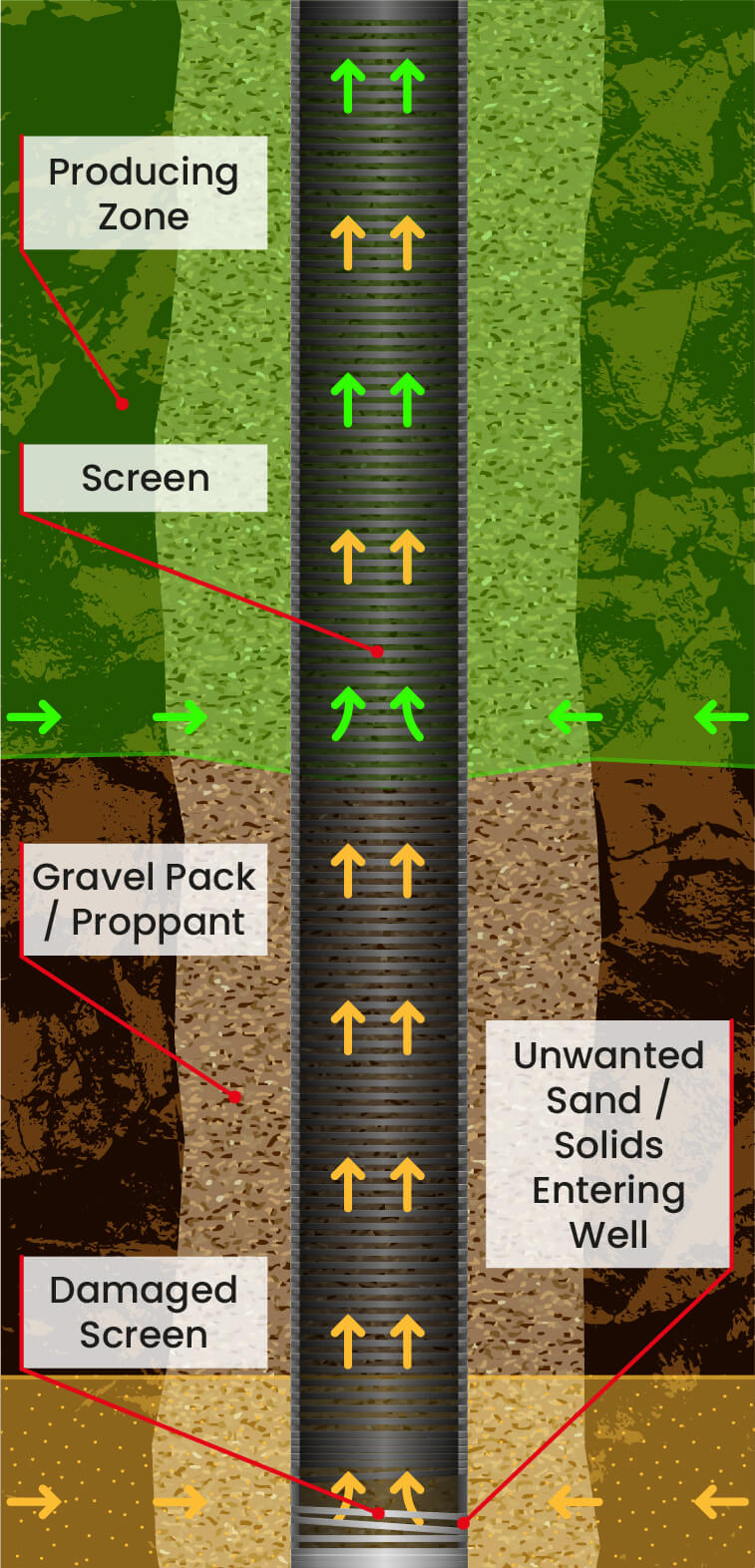

A 2.625” OD BiSN Wel-lok™ SCT tool was run on wireline, activated and set inside a 3-1/2” base pipe gravel pack screen to provide isolation inside the completion as well as out to the 7-5/8” liner to shut off all solid (sand) production from zones below the plug.

Given the depth and temperature where the BiSN plug would be set, specially designed high-pressure heaters rated to ~ 12,000 psi were used in conjunction with high temperature alloy capable of operating at temperatures up to 150⁰C, making this BiSN’s first High-Pressure High-Temperature (HPHT) deployment in a gravel pack completion.

The BiSN Wel-lok™ SCT tool has been specifically developed to achieve a barrier to flow in sand control completions. The deployment of the tool is truly a rigless solution without the need for any surface pumping equipment to circulate or squeeze the alloy in place.

Traditionally this technology has been used to reduce water production (also known as the Water Shut Off tool) from lower zones however, the applications are endless and as demonstrated in this case the tool was used to successfully target unwanted solid (sand) production.

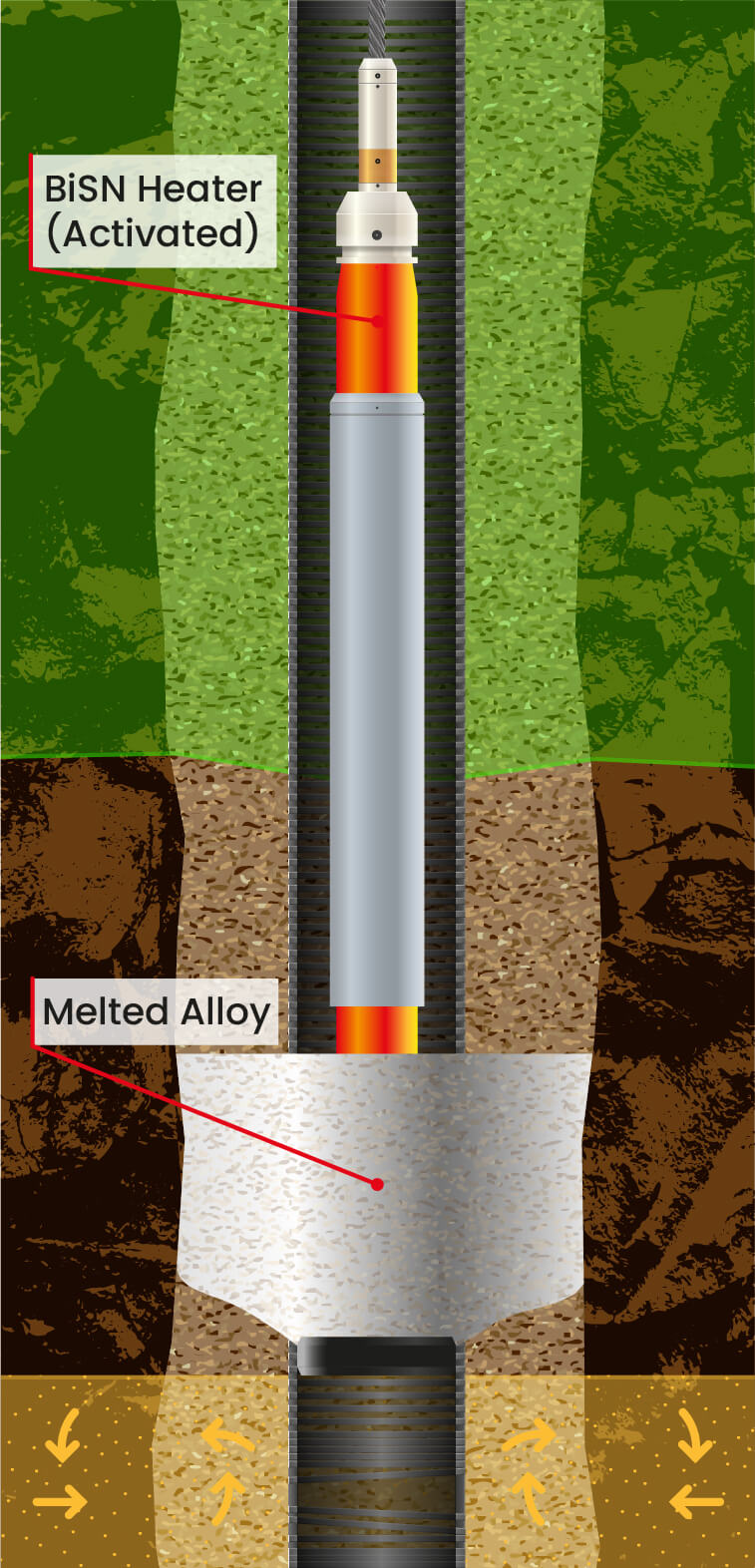

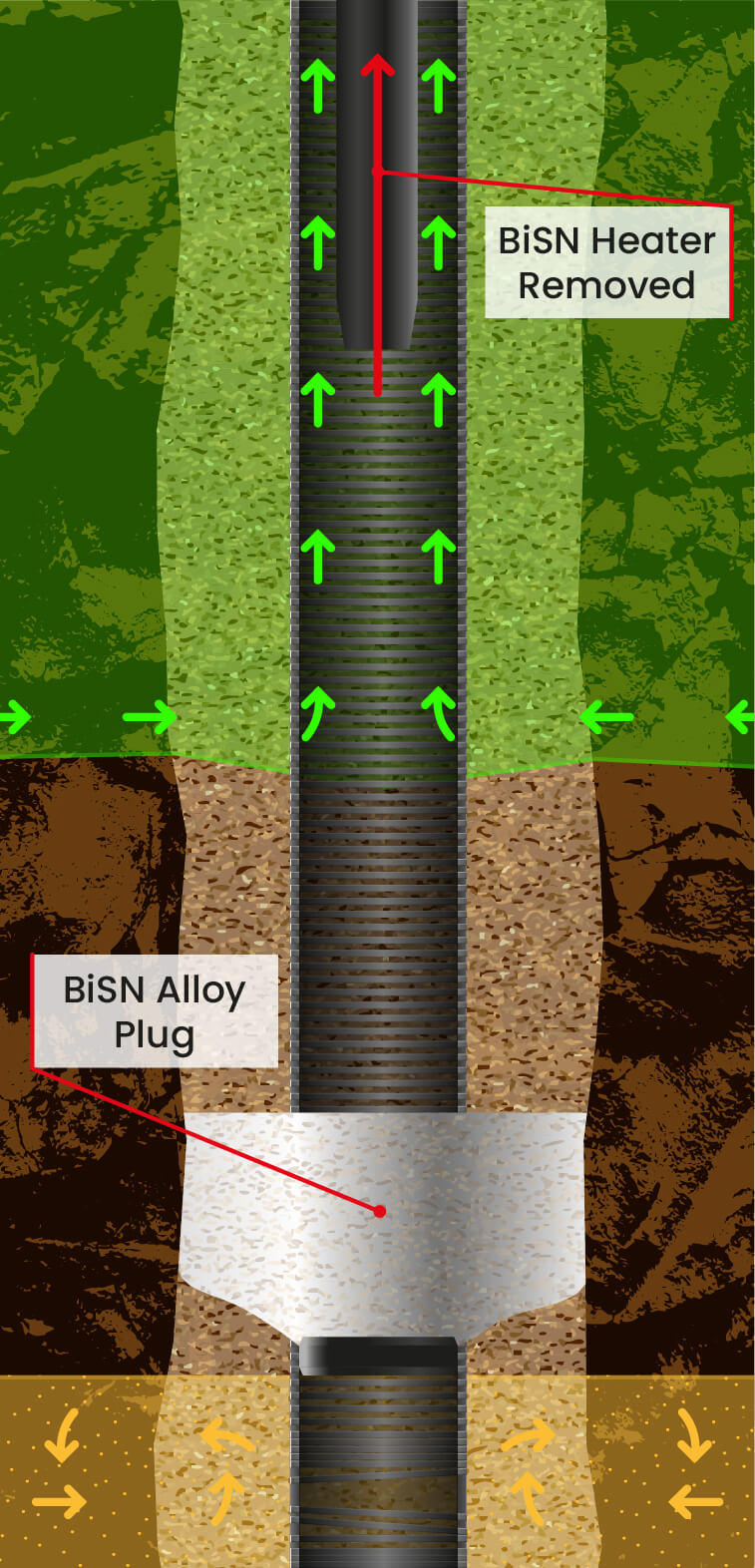

Due to the bismuth alloy’s viscosity and density, once melted (using a patented BiSN thermite heater) the liquid alloy flows under gravity into the annulus through perforations, sand screen and the minute gaps within the proppant/frac sand packed annulus to create a barrier to reduce or shut off flow from lower zones.

The impact was immediate for the operator.

By utilizing new rigless technology, we were able to bring the well back online in an efficient and cost-effective way.

Get in touch today to talk to our technical team.

The Wel-lok™ SCT (Sand Control Tool) has been developed to eliminate unwanted sand production by isolating both inside the completion string and in annulus of an open hole gravel pack completion (OHGP). This can be done without damaging the completion string with perforations or squeezing as is required for traditional methods. Due to its viscosity and density, the liquid alloy will flow through the sandscreen and into the open hole with gravity, completely isolating the sand producing zone.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies