Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Plug and Abandonment with Wel-lok™ Seal Through Casing (STC) Tool

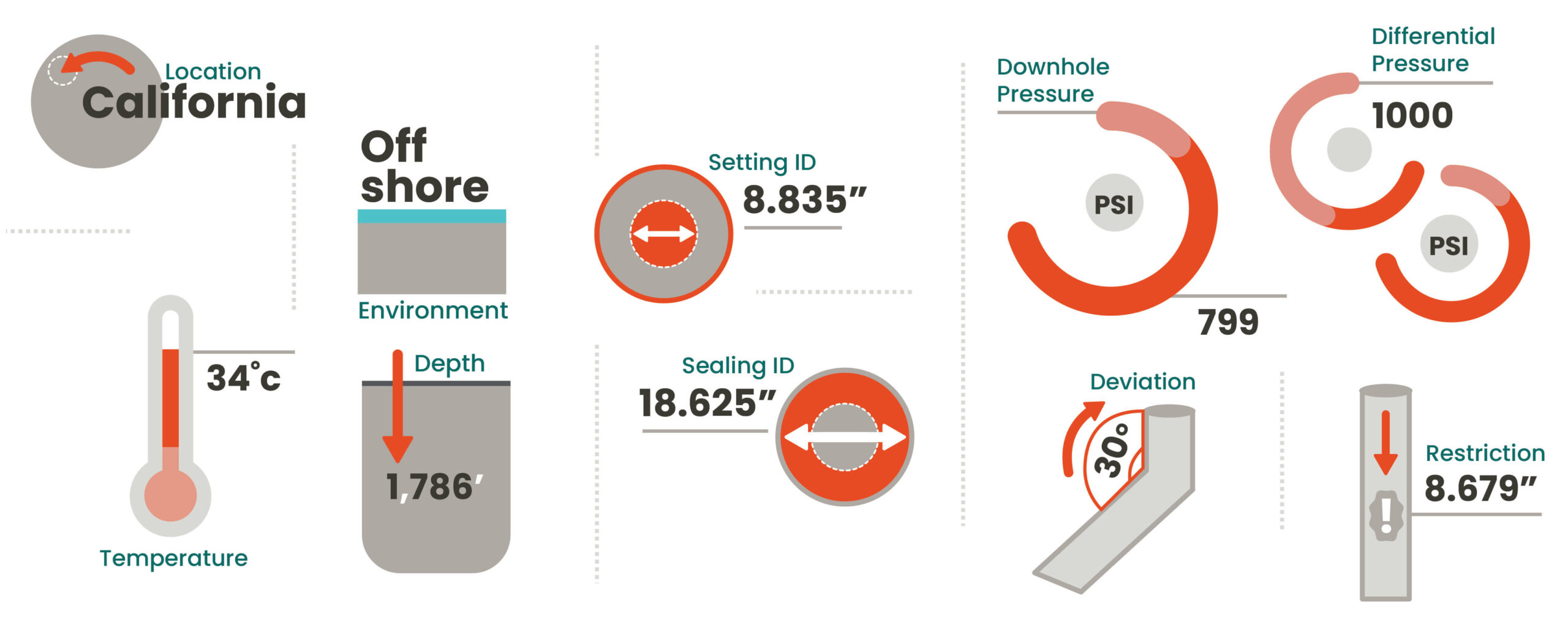

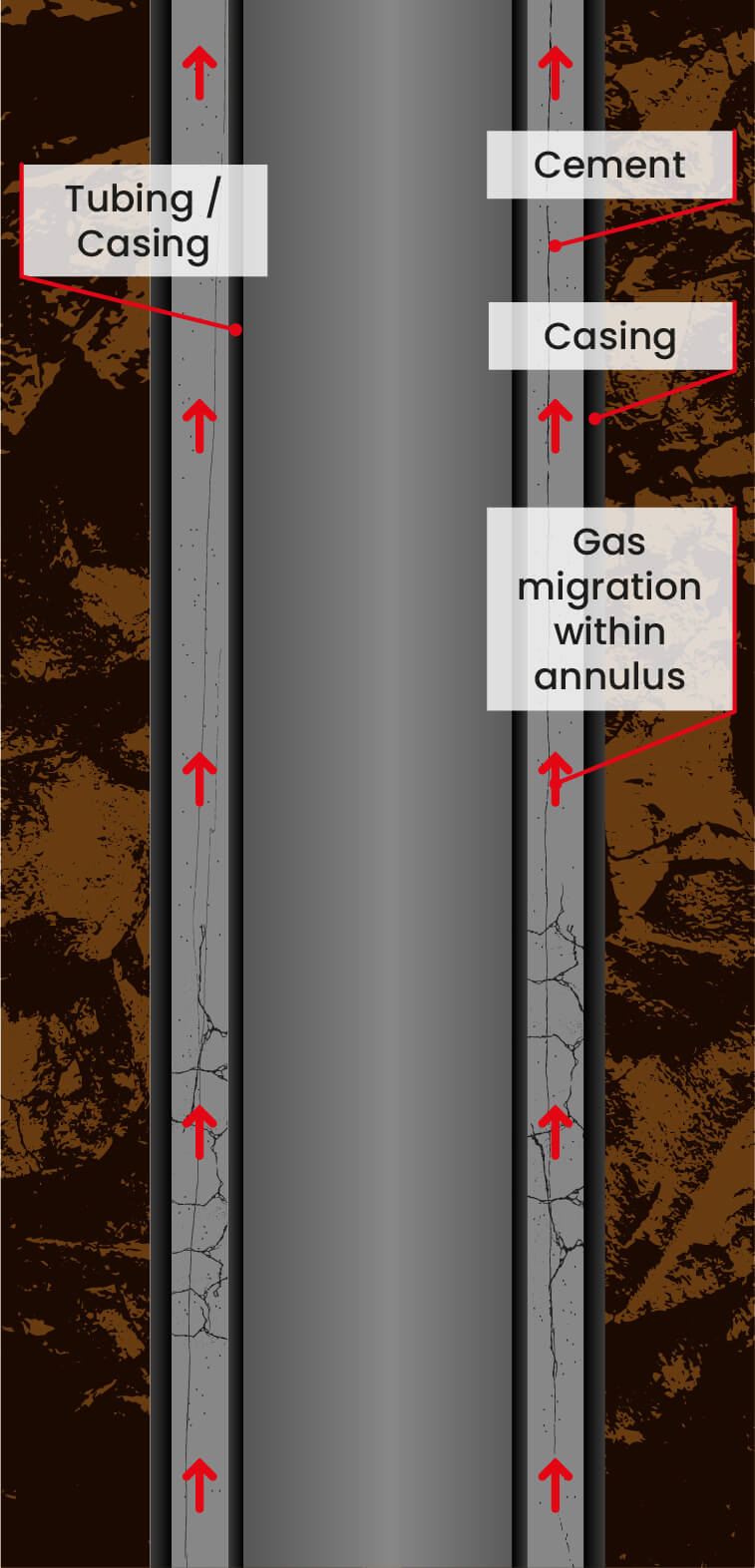

An offshore platform located in the Santa Clara field off the coast of California was being abandoned. The wells were experiencing pressure and gas bubbles in the C and D annuli behind the 9-5/8” and 13-3/8” casings.

The 9-5/8” was cemented in the 13-3/8” casing, and the 13-3/8” casing itself was cemented inside an 18-5/8” casing of its own. The customer needed a tool that could do two things effectively – be deployed through the 9-5/8” on drill pipe and set a plug that would shut off gas migration in both annuli for a permanent abandonment out of the 18-5/8”.

The customer had made three previous attempts at abandonment and was looking for a more cost-effective solution for successfully shutting off all gas migration in the annuli. We took an existing BiSN tool and redesigned its deployment method to accomplish the customer’s specific needs. BiSN’s Bismuth-based alloy plugs are non-porous and non-corrosive and they expand into the casing to create a gas-tight seal. In total, using a BiSN plug leads to millions of dollars of savings that operators traditionally need to spend on costly section milling.

The tools needed to be deployed through the 9-5/8” casing on drill pipe. In order to make a 5 ft plug in the pipe’s 18-5/8” annulus, a certain amount of BiSN alloy needs to be deployed. Traditionally, this would be done by casting it directly onto the outside of the heater itself.

But the tool’s design is limited by two factors. Firstly, the well’s restrictions (9-5/8” casing) meant that the tool’s diameter could not be any bigger than 8.00” to successfully drift and make it down to its setting depth.

Secondly, making a plug to seal all the way out to the 18-5” casing requires a certain amount of energy to melt the alloy. This also meant that the heater’s diameter could not be made smaller to accommodate the volume of alloy by casting it on the outside.

In other words, using the traditional approach was not possible without making the tool itself extremely long.

Due to the well’s location off the coast of California, this project also had a critically high environmental impact.

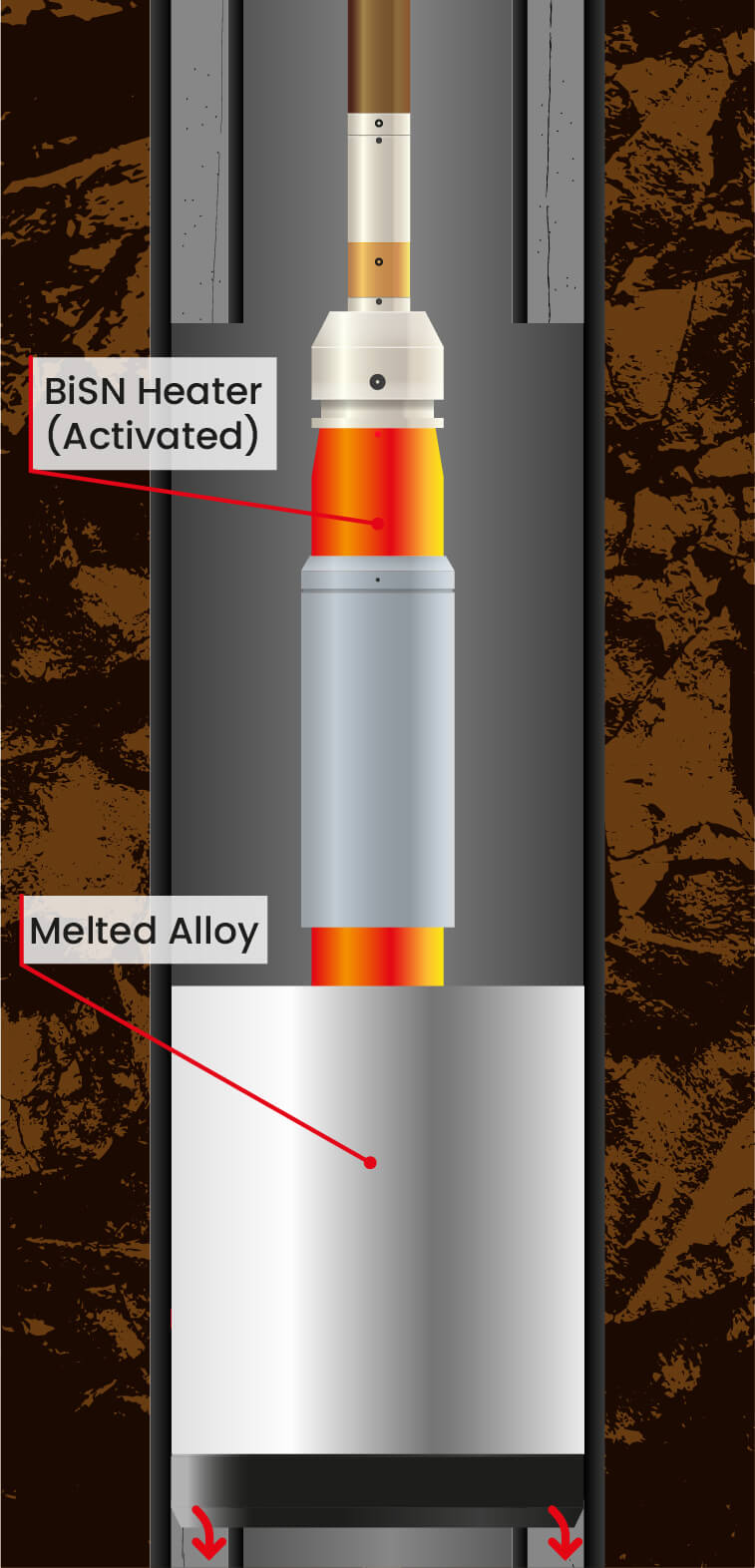

By redesigning the alloy deployment mechanism, we were able to deploy the alloy in the form of small beads, instead of trying to cast it onto the heater itself where there were diameter restrictions.

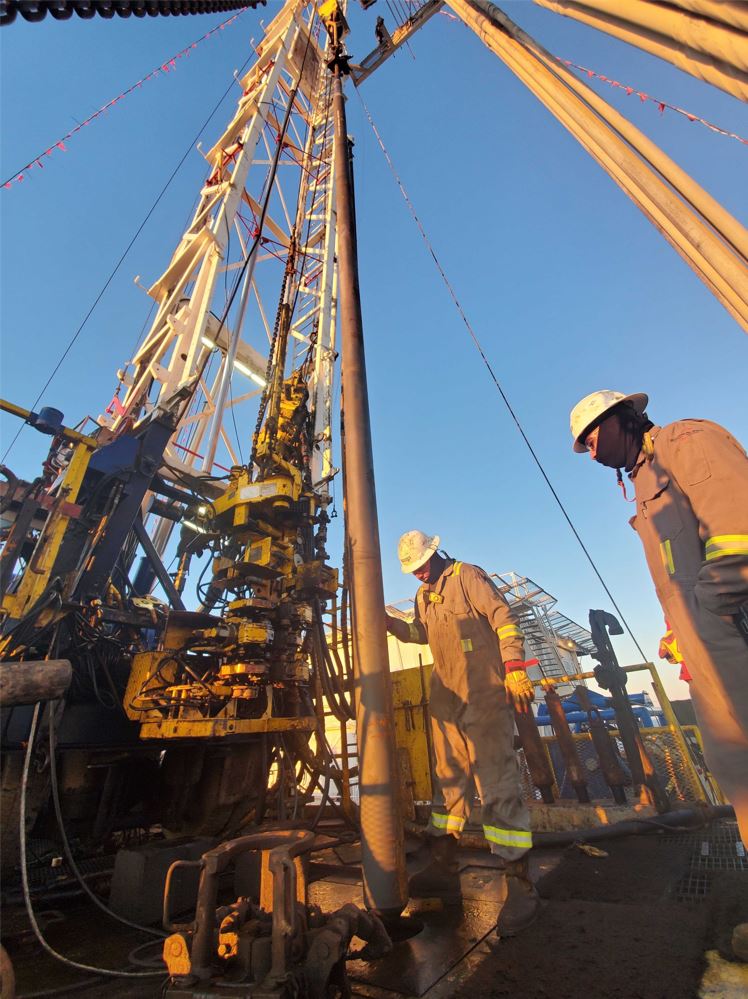

Using the BiSN Bottom Hole Assembly (BHA) which included the bare heater and the running tool, we designed a solution that was able to be deployed on drill pipe using a specially created ported sub on top.

Once the tool was at setting depth, BiSN alloy beads were introduced into the drill pipe from the surface via the ported sub, gathering around the heater inside the section milled 18-5/8” casing. The heater was then ignited, melting all the alloy beads to make the plug. Then, the heater was retrieved, creating a full cross-section gas-tight alloy seal, and completing permanent abandonment.

Our BiSN Wel-Lok™ STC tool has been specifically developed to create a permanent barrier for abandonment through multiple casings and annuli, either through perforations or section milled windows.

Unlike cement, which requires hundreds of feet, the BiSN tool creates a gas-tight seal in just a few feet. It can also be deployed on both wireline and drill pipe.

This successful project provided the customer with a more dependable and reliable seal than traditional cement. On top of the time and cost savings, our molten alloy solutions eliminated the need for surface pumping equipment.

Permanent abandonment was achieved through maximum innovation and minimum time and cost for the supermajor operator in question.

Are you looking for a cost-effective and sustainable solution for your business? Contact our technical team today.

The Wel-lok™ STC (Seal Through Casing) has been developed to achieve a gas tight V0 seal well annuli that cannot be achieved by traditional cement balance plugs. Run on electric line, this tool does not need surface pumping equipment to circulate the alloy in place. Due to its viscosity and density, once melted the liquid alloy will flow with gravity into the annulus. When it cools below its melting point it solidifies, expands and creates a gas tight seal across the entire wellbore. The entire process, from melting to solidification, takes place in minutes and the seal is ready to test within an hour.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies