Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Well Intervention with Wel-lok™ TS

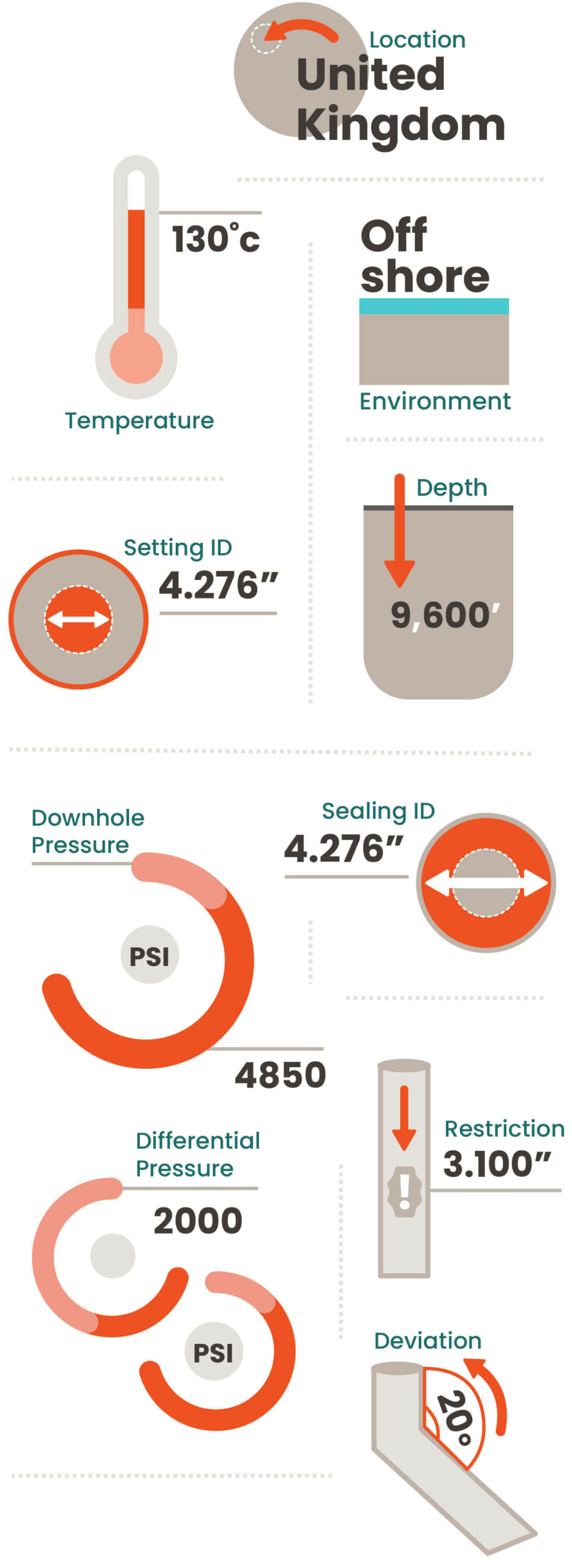

Two V0 rated mechanical plugs had previously been set in this well as suspension plugs but gas continued to leak past them to surface.

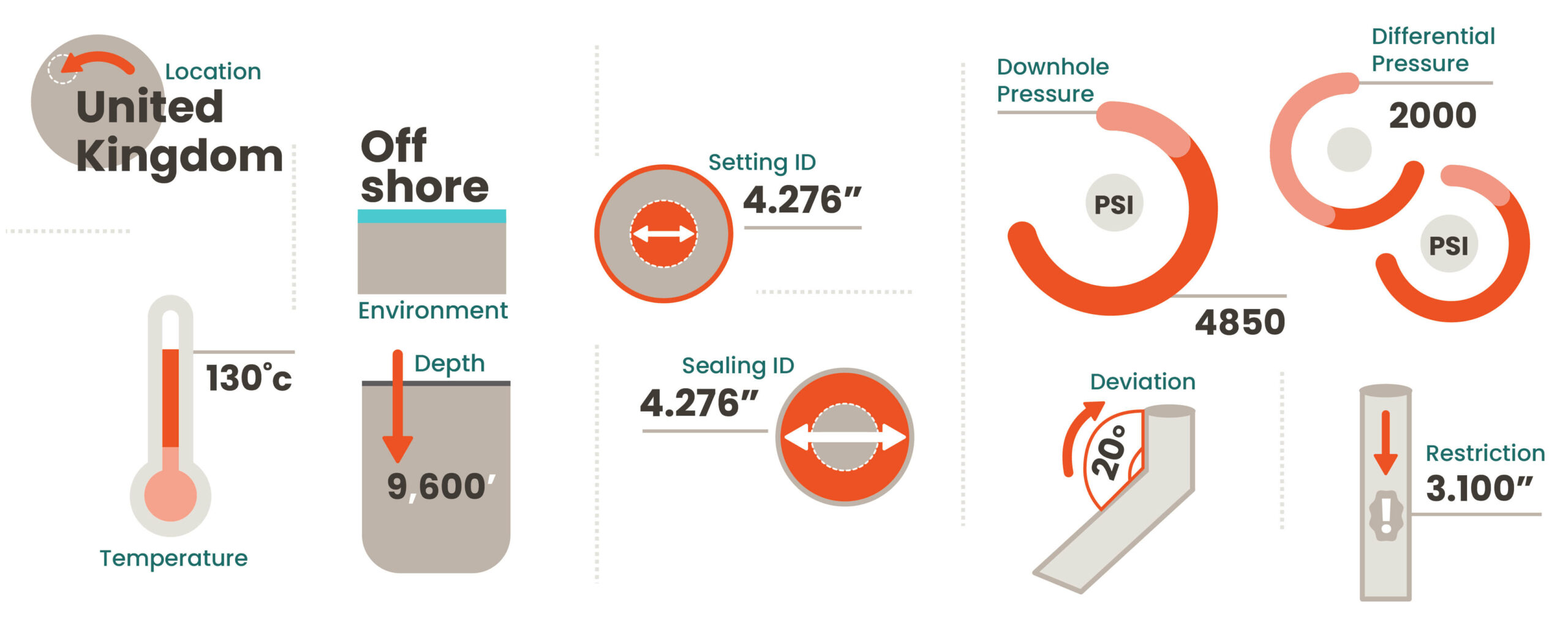

The well had 5” tubing that with a kink in it which prevented full drift tools from passing through. This required a tool with a maximum OD of 3.0” to seal inside a 4.276” ID at 130 °C.

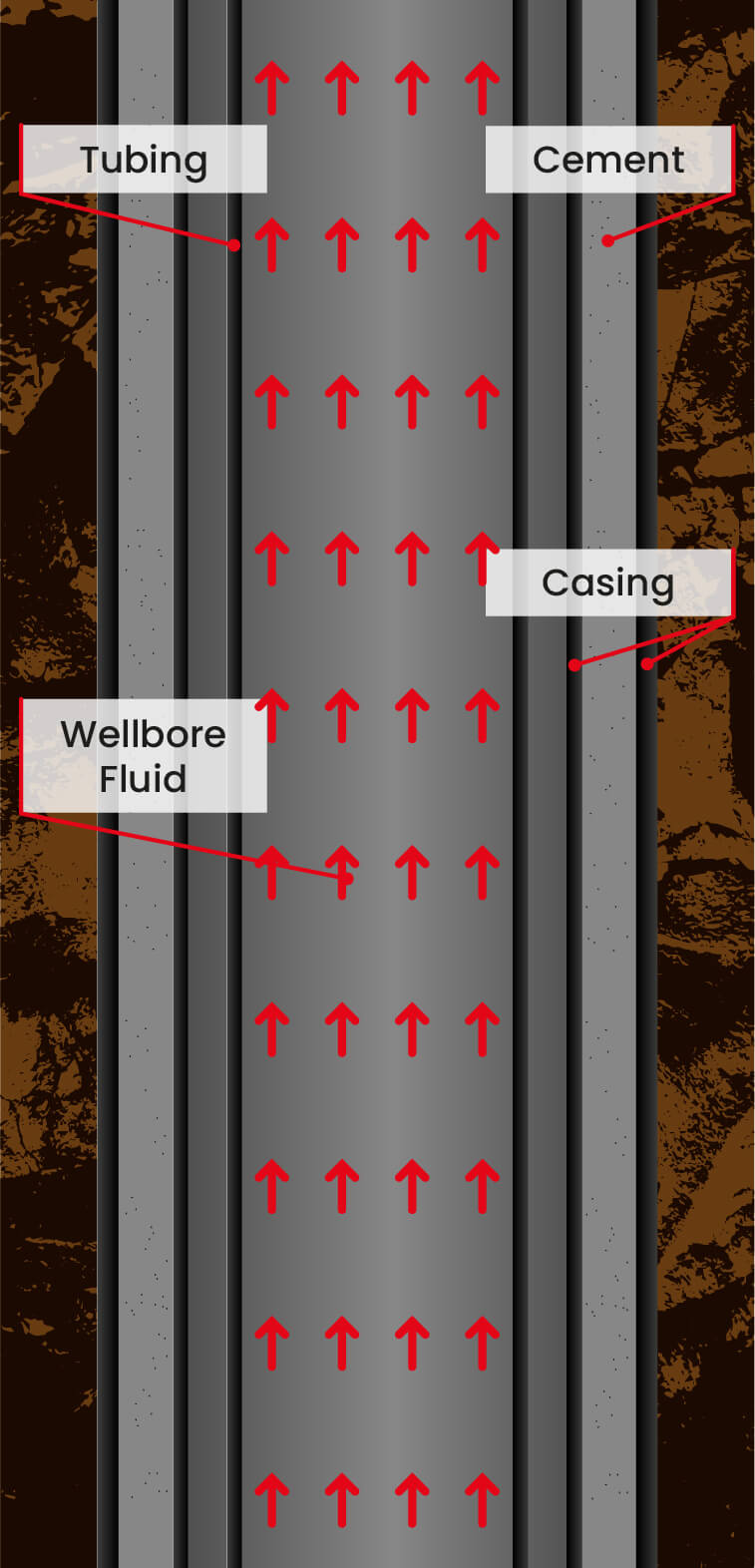

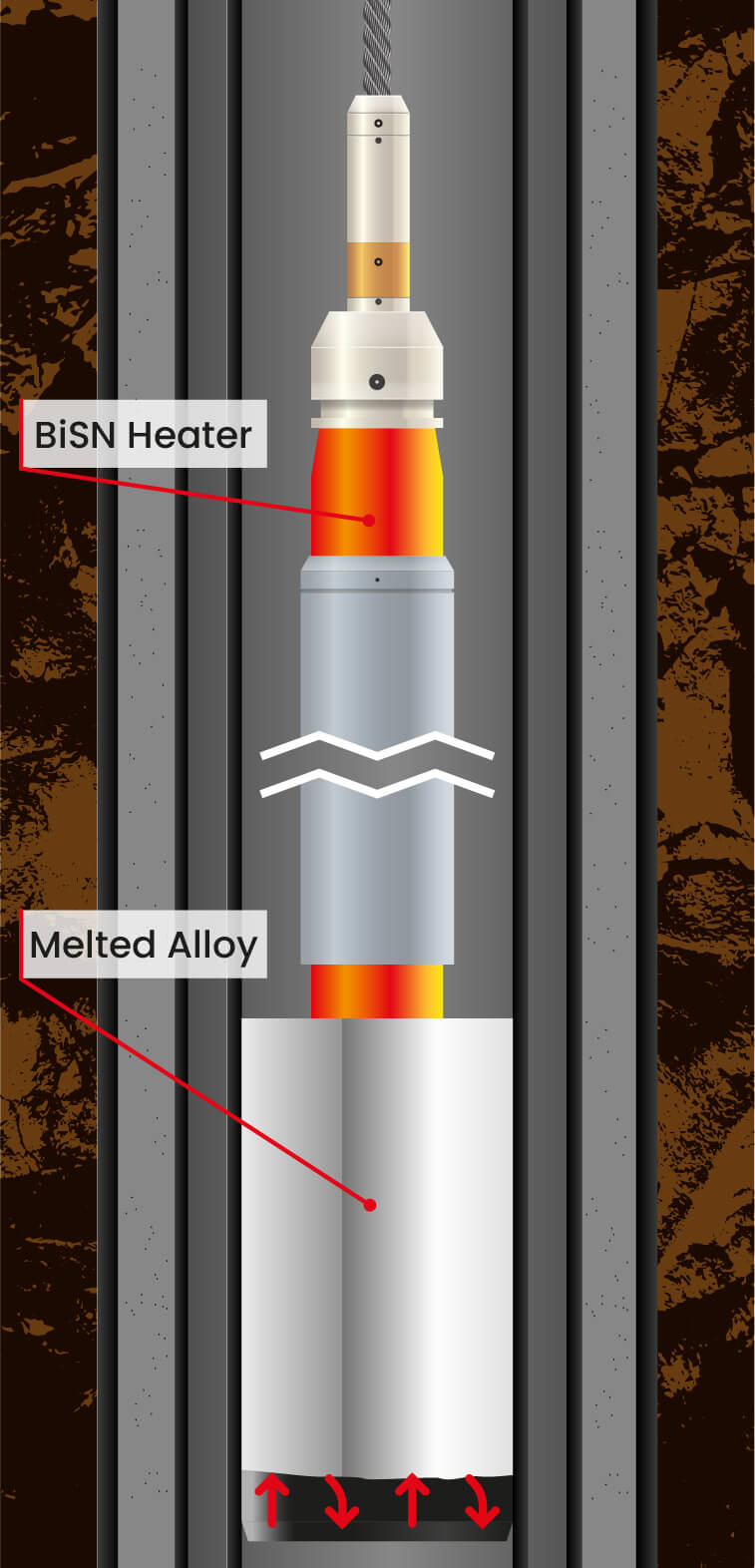

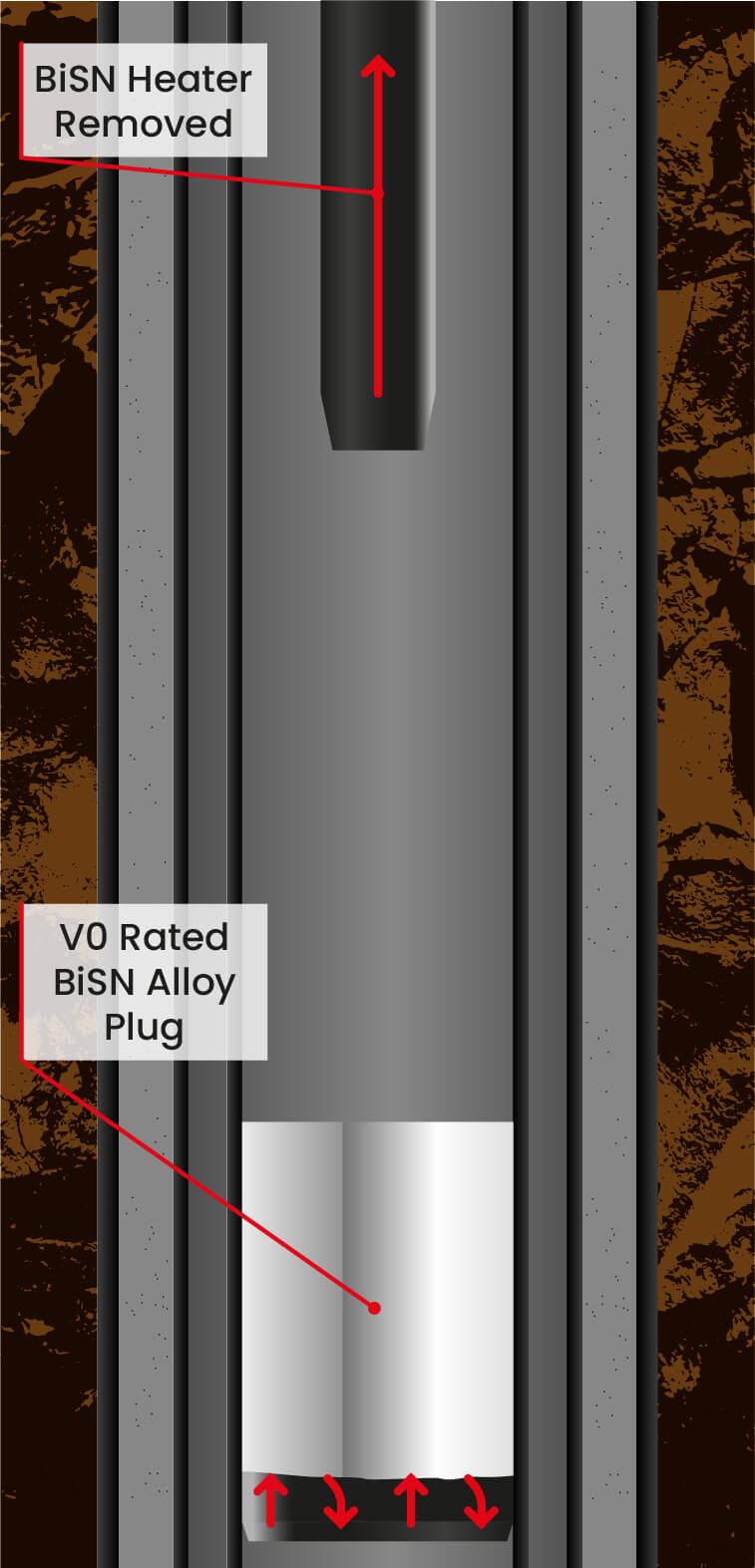

A Wel-lok™ TS tool was set inside the tubing above the previously set mechanical plugs.

This tool was qualified to 7,000 psi at our testing facility in Houston, TX. After being run in the well, it was successfully pressure tested to 1,400 psi in addition to a negative pressure test which confirmed there was no longer a gas leak to surface.

The Wel-lok™ TS (Tubing Seal) was developed to overcome the shortcomings of traditional methods, using bridge plugs and cement during well abandonment. It is typically run on electric line but can be deployed on a slick line or coil tubing as well. It can pass through small restrictions such as damaged or crushed tubing, yet still create the gas tight seal. It has a higher expansion ratio than conventional plugs, higher pressure ratings than inflatable packers and gas blocking abilities that cement cannot match.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies