Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

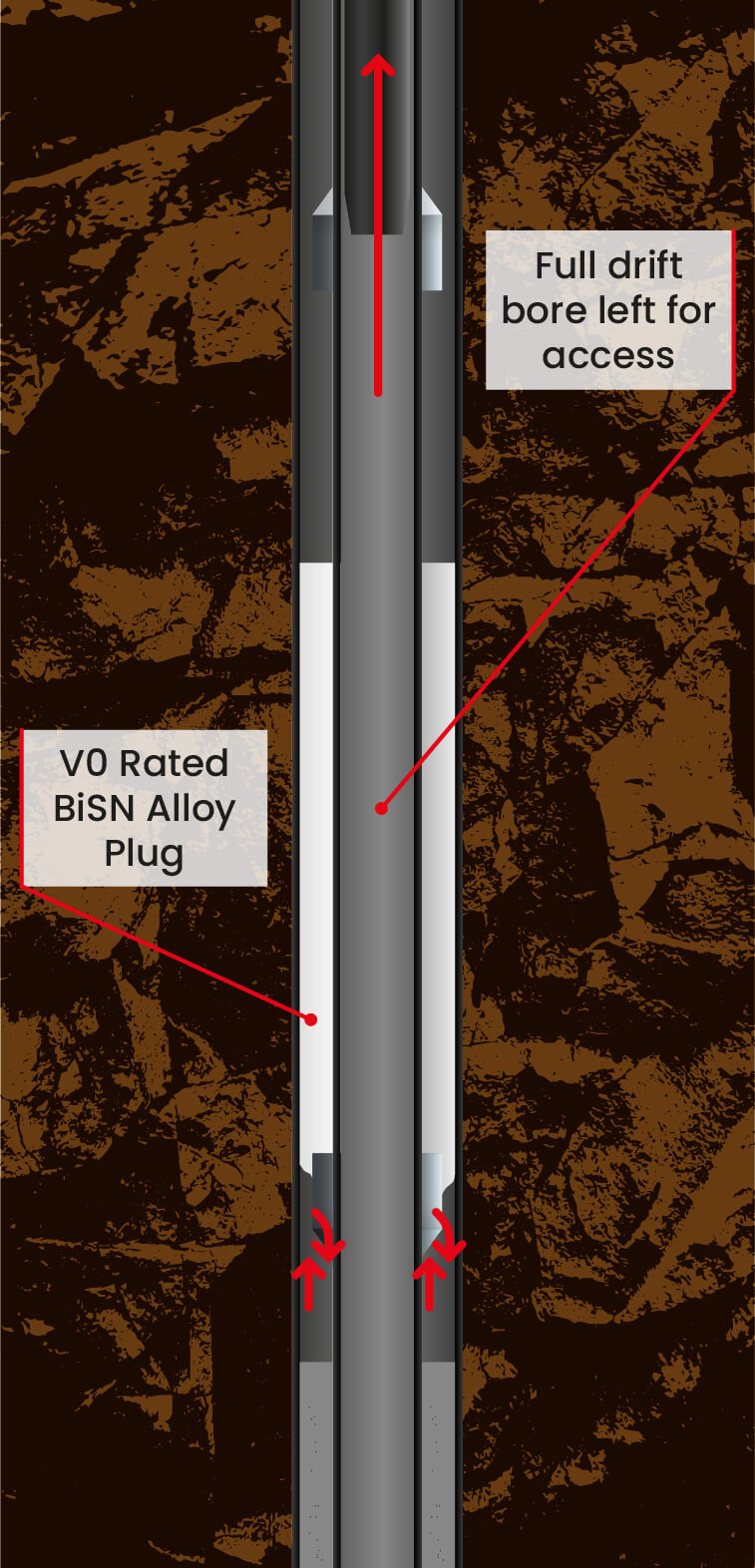

Well Completion with Wel-lok™ TDAP

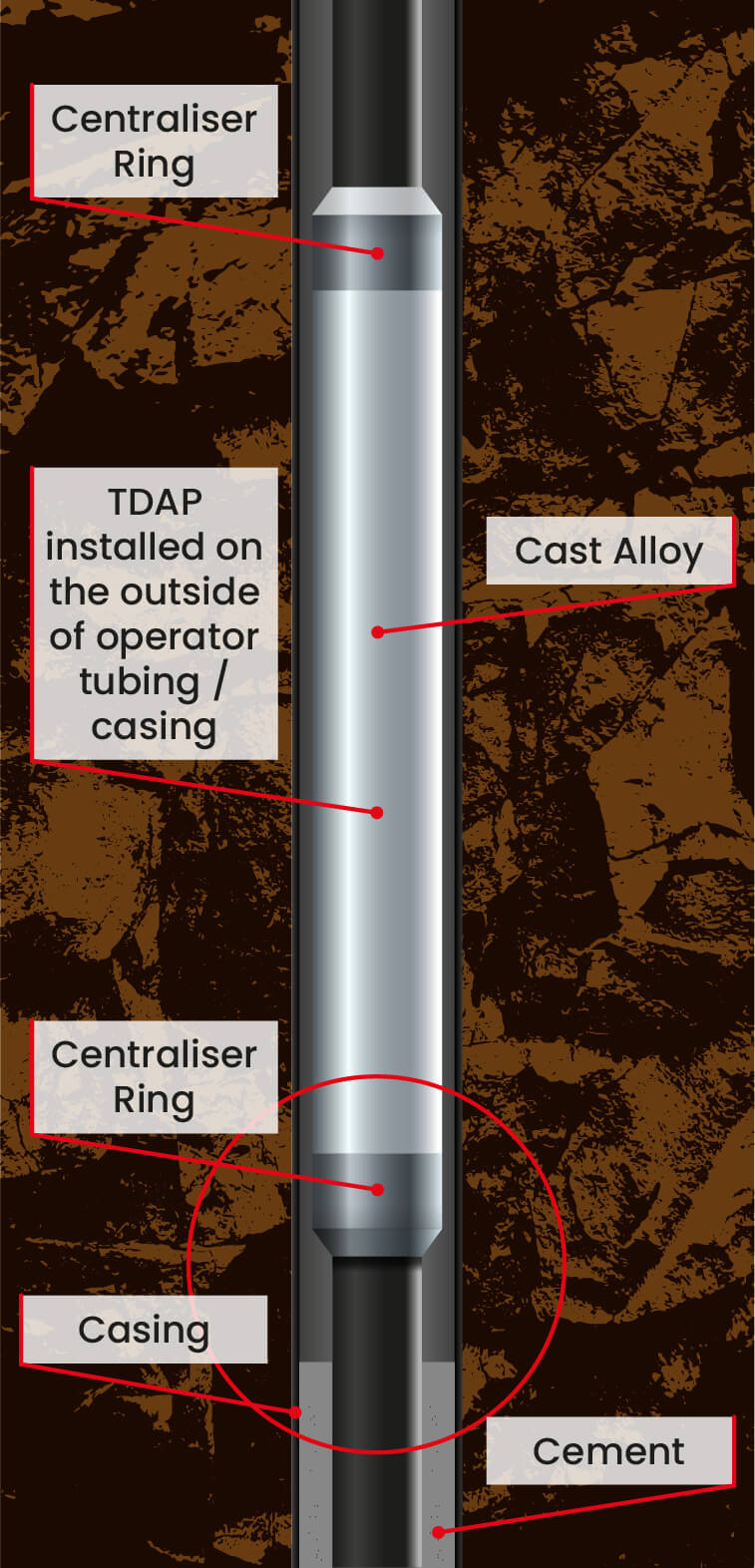

The Wel-lok™ TDAP was designed to be specifically applied during the well construction stage. This is a bespoke innovation which is adapted for annular sealing. Traditionally elastomer seals and cement have been used for decades to seal the annulus between casings. As many field engineers will testify, the elastomers and cement are known to have a high failure rate, having to be remediated using cement or resin squeezes. These are expensive, difficult and unreliable workovers. With the TDAP pre-installed in the annulus, annular pressure can be addressed by running a heater inside the casing to melt the alloy and seal the annulus in a simple, cost effective and reliable way.

The bismuth-based alloy has no porosity and solidifies to create a seal in minutes as opposed to hours with traditional cement and resins, eliminating the possibility of a micro-annulus being formed to allow future gas migration.

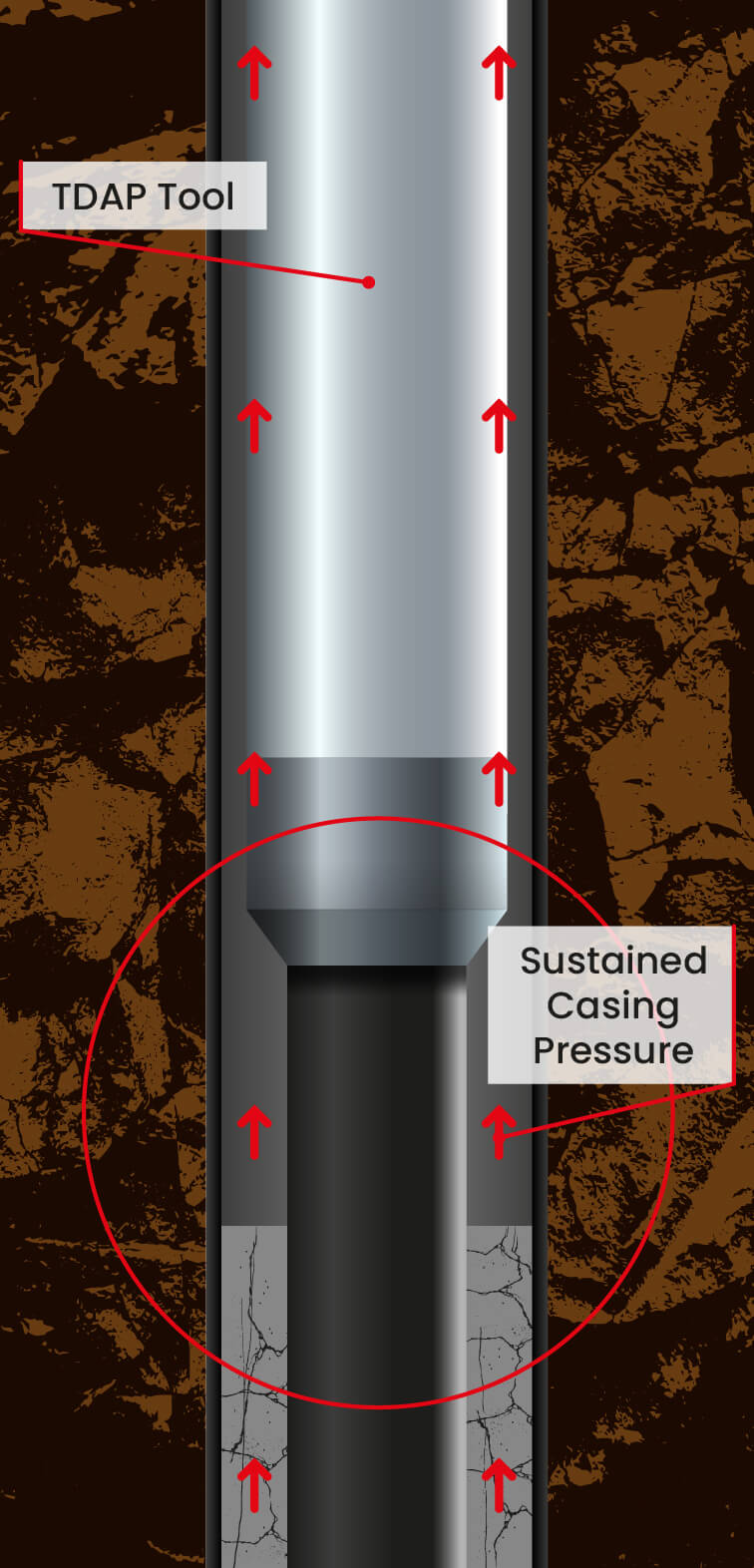

The operator is currently installing TDAP’s on all of their new drill wells. On one pad, 15 wells were constructed with 5 ½” production casing, placing the TDAP on the outside of a joint of casing and below the surface casing shoe in 8.5” open hole. When the time came to perforate and frac the wells for production, 7 of the 15 wells were found to have sustained casing pressure as high as 750 psi. Due to local regulatory requirements, the operator required this to be addressed before any further work could be conducted on these well.

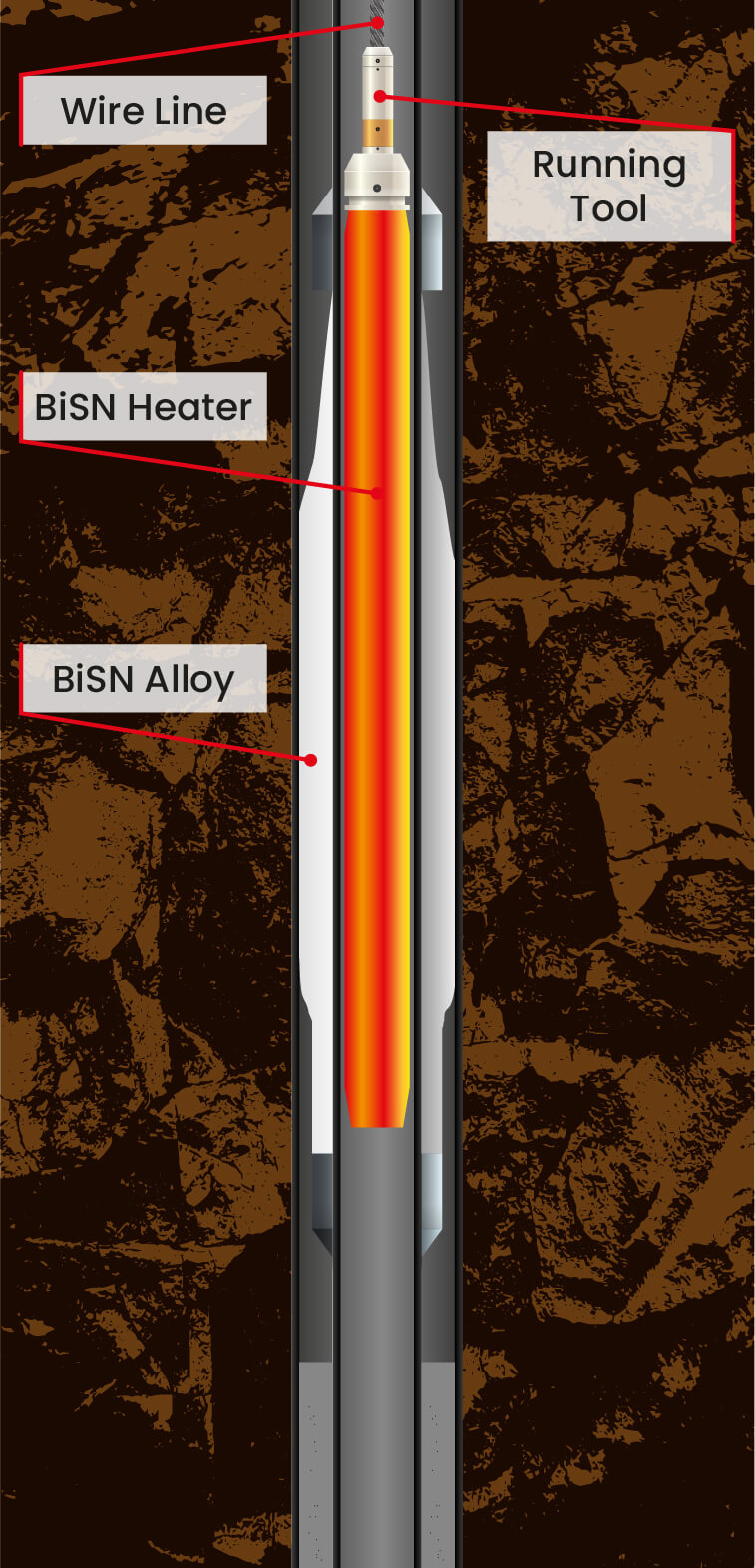

With the TDAP’s already installed in these wells, the operator contacted BiSN to arrange for heaters to be mobilized. In each of the 7 wells, a heater was run inside the 5 ½” casing on wireline with no rig support (rigless). The heater was activated by applying 240V for 30 seconds, starting the chemical reaction and melting the alloy on the outside of the casing without damaging the casing itself. The liquid alloy, with its low viscosity and high density, filled the annulus, taking the shape of the open hole, and solidified. With a unique property of expanding on solidification, this created an impermeable gas tight seal in the annulus, stopping all gas migration.

Each well was successfully bubble tested then shut in to reveal no pressure build up. With pressure eliminated, the operator was able to move forward with their plans to perforate, frac, complete and produce the wells. Similar operations, with the same results, were performed previously on a well in the Permian Basin during the production phase of the well.

Traditional methods of intervening in a well with sustained casing pressure is unreliable and requires damage to the casing via perforations. This compromises the integrity of the casing for the life of the well and the holes must be covered with a casing patch, creating a restriction in the casing that may require a special completion. By proactively installing the TDAP during well construction, the impermeable seal can be created at any phase of the well’s life, from pre-fracking to abandonment, without altering the integrity of the well.

The Wel-lok™ TDAP (Thermally Deformable Annular Packer) was developed as a preventative tool to be run as part of the original casing string. It is run on an inner casing string and the tubing cemented into place. After cementing the tubing, the TDAP™ is set by running a chemical reaction modified thermite heater inside the casing to melt the alloy and create a gas tight seal in the annulus, eliminating the possibility of future casing vent flow when the cement in the annulus ultimately degrades and develops micro-annuli. If utilised in the design of the well, this tool can eliminate future expensive interventions and unreliable cement squeezes required to address surface gas pressure through cemented annuli.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies