Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

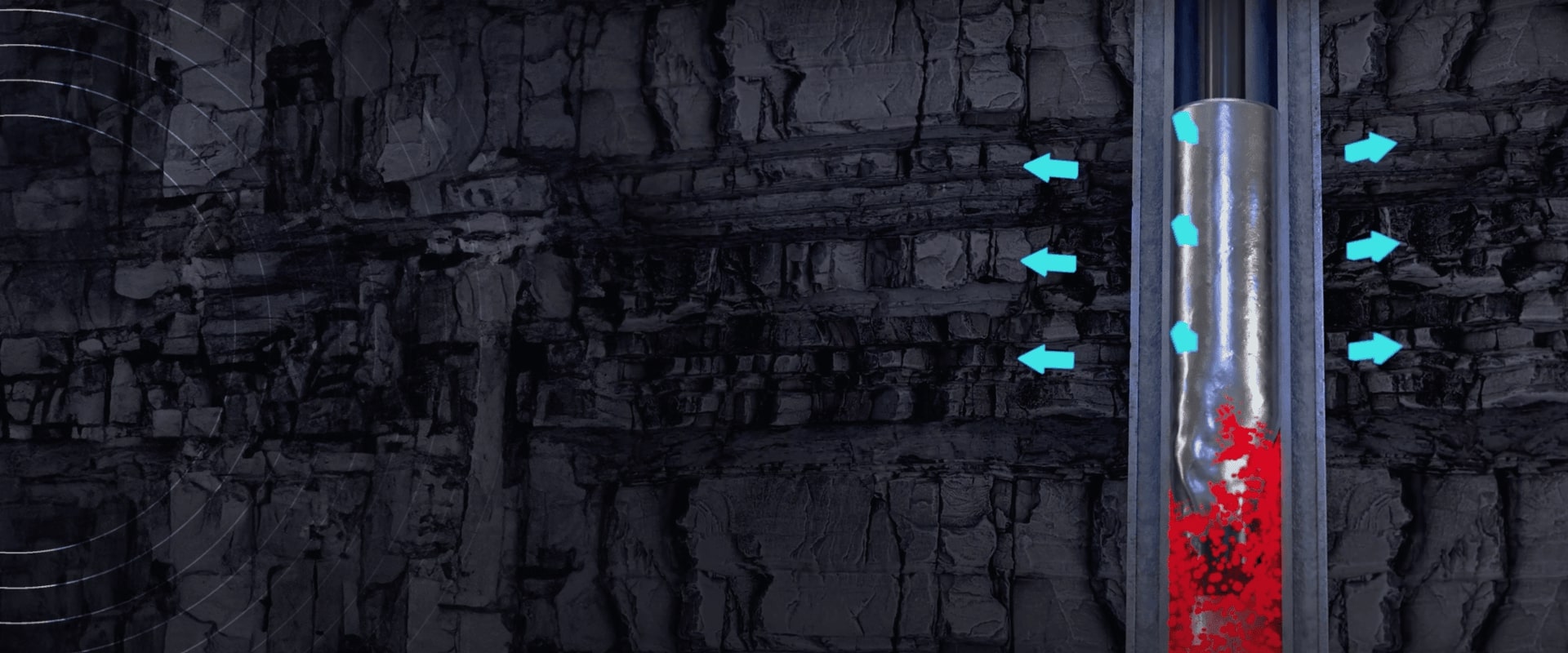

When a depleted zone requires ‘zonal’ isolation to allow production to continue from higher ‘interfaces/zones’, operators require the need for high expansion seals with high differential pressure capabilities or a short plug/seal due to limited space between zones.

Wel-lok™ offers seals that maintain the same pressure rating regardless of how much expansion is required, unlike other high expansion plugs.

This provides operators the benefit of pressure integrity needed over a very short interval with a short plug.

BiSN overcomes the shortcomings of traditional methods of setting bridge plugs using cement, delivering savings in both speed and cost with the Tubing Seal tool.

Developed to be run on wireline, slickline or coiled tubing, the BiSN tool passes through small restrictions such as damaged or crushed casing before setting a gas-tight plug that can be used for isolation, thanks to the BiSN alloy being able to seal a larger diameter with a smaller tool relative to conventional bridge plugs.

The Wel-lok™ TS (Tubing Seal) was developed to overcome the shortcomings of traditional methods, using bridge plugs and cement during well abandonment.

View tool details

BiSN engineers were challenged to further increase the expansion ratio beyond that of the original system without compromising its pressure differential and gas-tight sealing capabilities.

By incorporating a bailer in its configuration, the tool is able to be deployed on a single run alongside the thermite heater without having to pump beads down from the surface. This allows for a smaller diameter tool to be run in hole while increasing the expansion ratio up to three times the OD of the tool.

The result is a higher expansion ratio than conventional plugs, higher pressure ratings than inflatable packers and gas blocking abilities that cement cannot match.

Download Spec SheetThe Wel-lok™ MXD (Maximum Drift) has been specifically developed for rigless through tubing applications.

View tool details

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies