Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Innovative downhole solutions for Oil & Gas operators.

Perfected by science.

Proven in the field.

BiSN’s innovative bismuth-based sealing technologies – wel-lokTM extend the life of your well and permanently solve downhole flow issues so you can maximize production from all your assets.

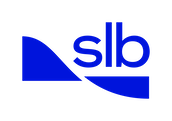

Sealing methods that use non-permanent materials alone such as cement, elastomers and resins cannot solve well issues like water production and gas migration reliably for the long term.

BiSN’s unique field-proven Performance Barrier Technologies allow operators to solve unwanted downhole flow issues once and for all – sealing across the life of the well with confidence to assure uptime, improve production, extend well life and ultimately to abandon safely, and forever.

Discover BiSN Technology

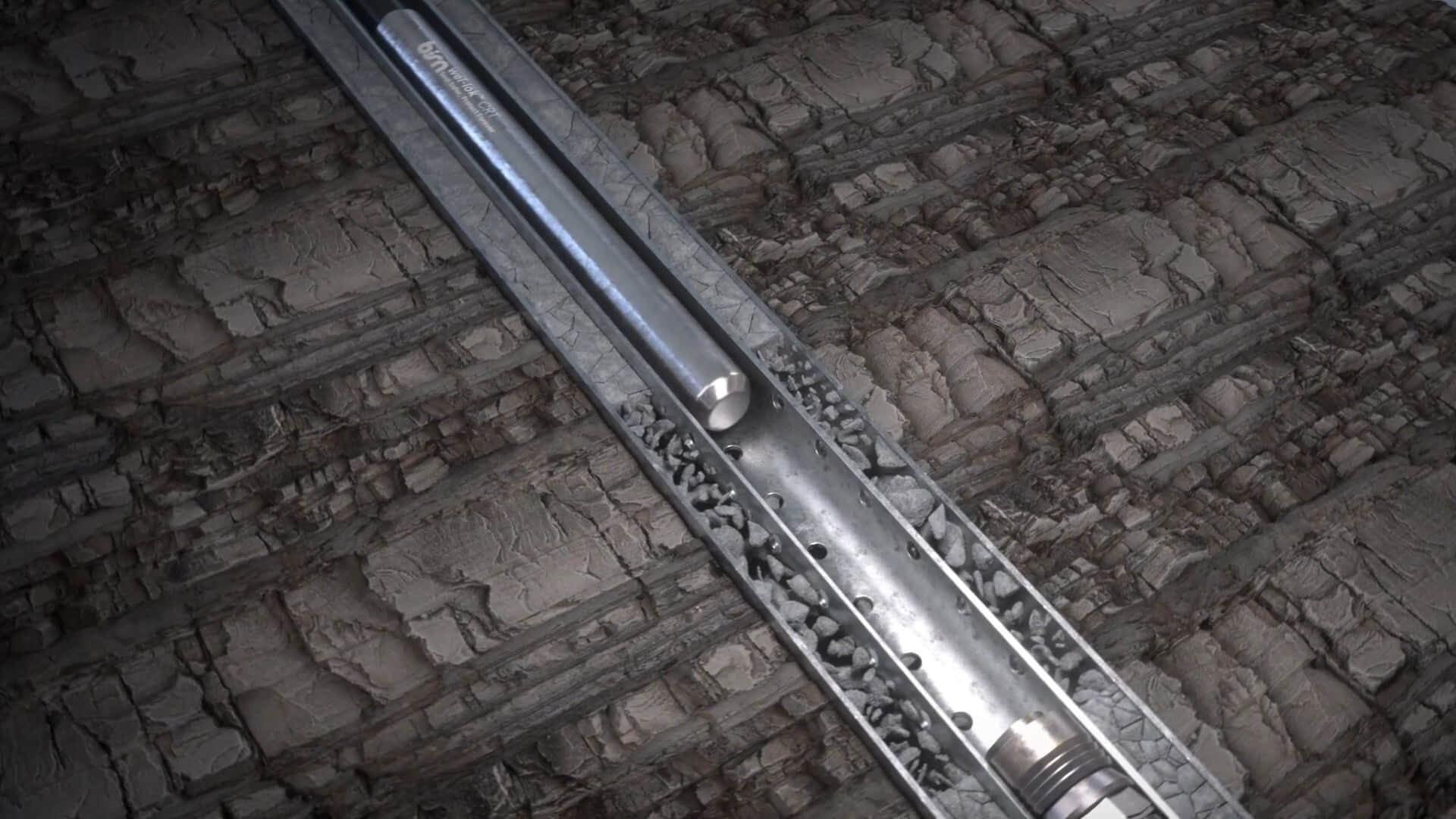

Developing unmatched Performance Barrier Technologies that deliver a superior seal that endures demands original thinking in materials science, engineering and manufacturing.

Learn about Technology

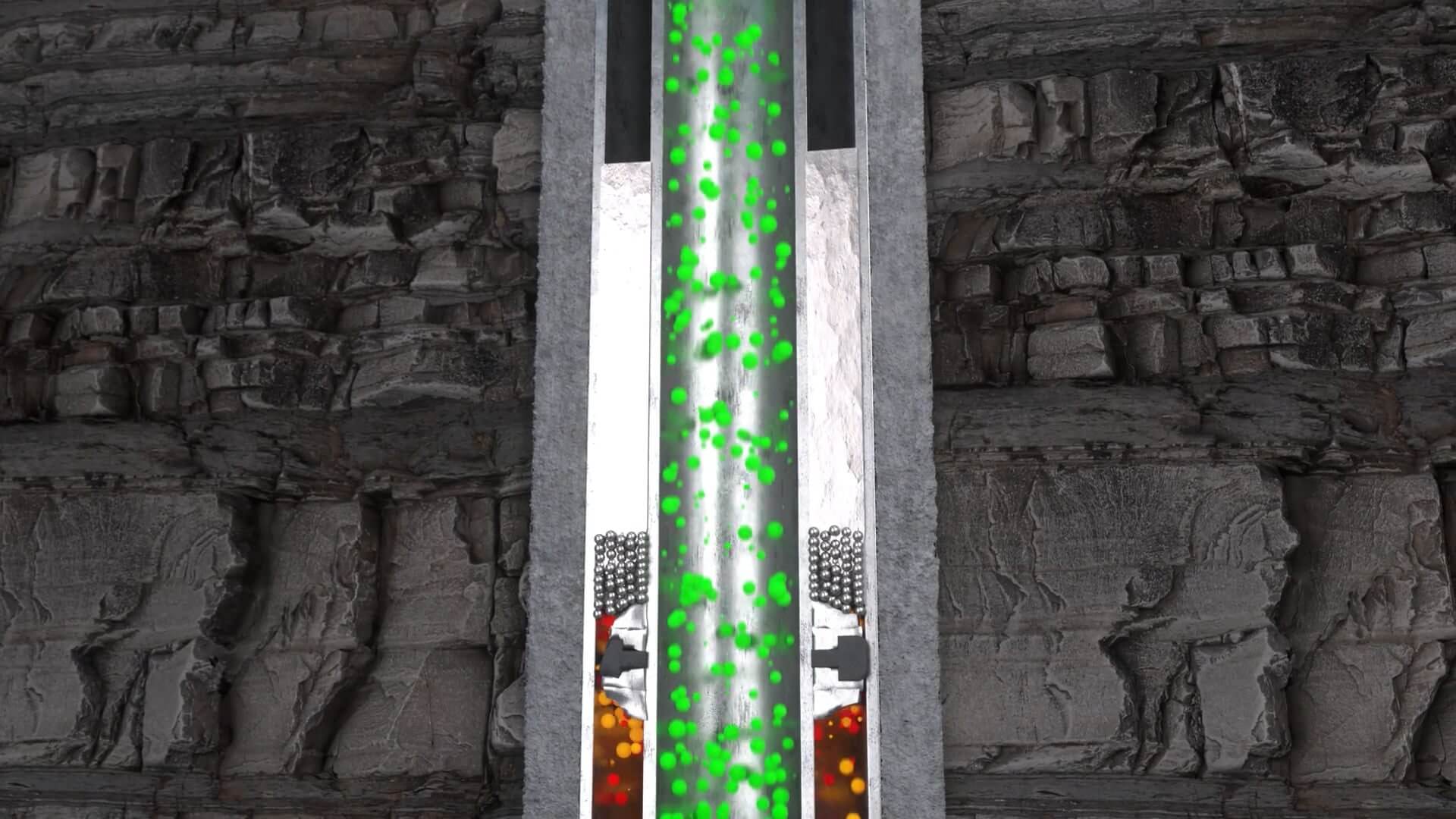

Bismuth-based alloy barriers. Led by innovation. Made possible by perfected thermite chemical reaction heaters and unique conveyance methods. For the life of your well, and beyond.

Protecting your production, your people and the environment for the long term demands operators can hold back downhole liquids and gases reliably and definitively.

Performance Barrier Technologies from BiSN utilize patented sealing alloys — enabling precise placement of a high endurance, gas-tight seal.

Bismuth-based alloy well solutions. Led by innovation. Powered by thermite.

Performance Barrier Technologies from BiSN utilize patented sealing alloys — enabling precise placement of a high endurance, gas-tight seal.

Learn about the Technology

Businesses worldwide are benefitting from our innovative downhole solutions.

Our performance barrier technologies have been proven in the field hundreds of times across all regions, onshore and offshore, high pressure/temperature/deviation sealing casing/tubing from 3.5”OD to 30”OD. Discover the range of downhole challenges faced by operators, and how BiSN has helped address them.

Videos explaining the BiSN Technology.

Shut off water producing zones with the Water Shut Off (WSO) tool, seal through multiple annuli in a single run with the Seal Through Casing (STC) tool, repair leaking production packers with the Packer Repair Tool (PRT), plus many more….

Stay ahead of the curve and learn how wel-lok™ can augment your current remediation and abandonment processes.

See more videos

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies