Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

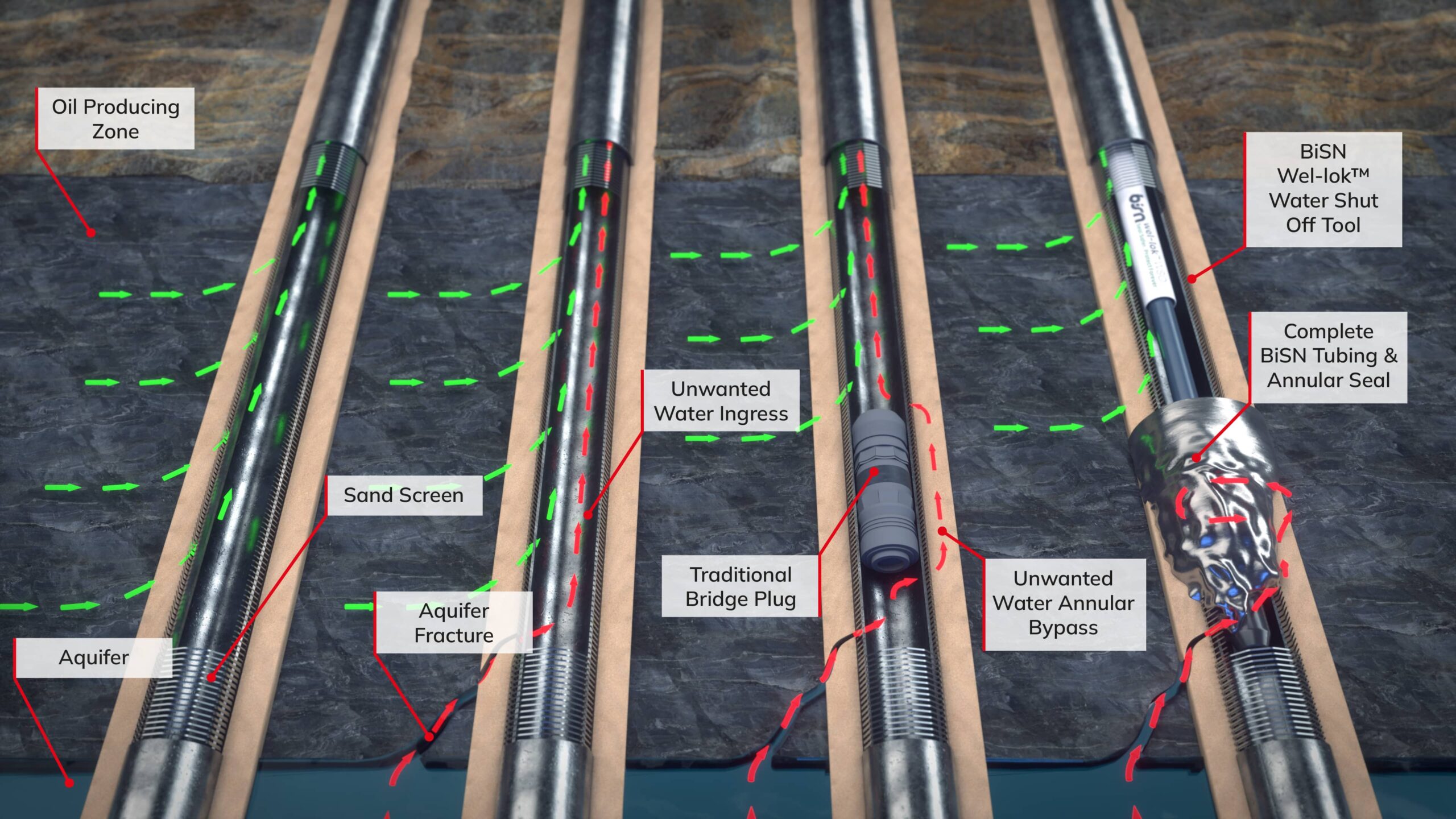

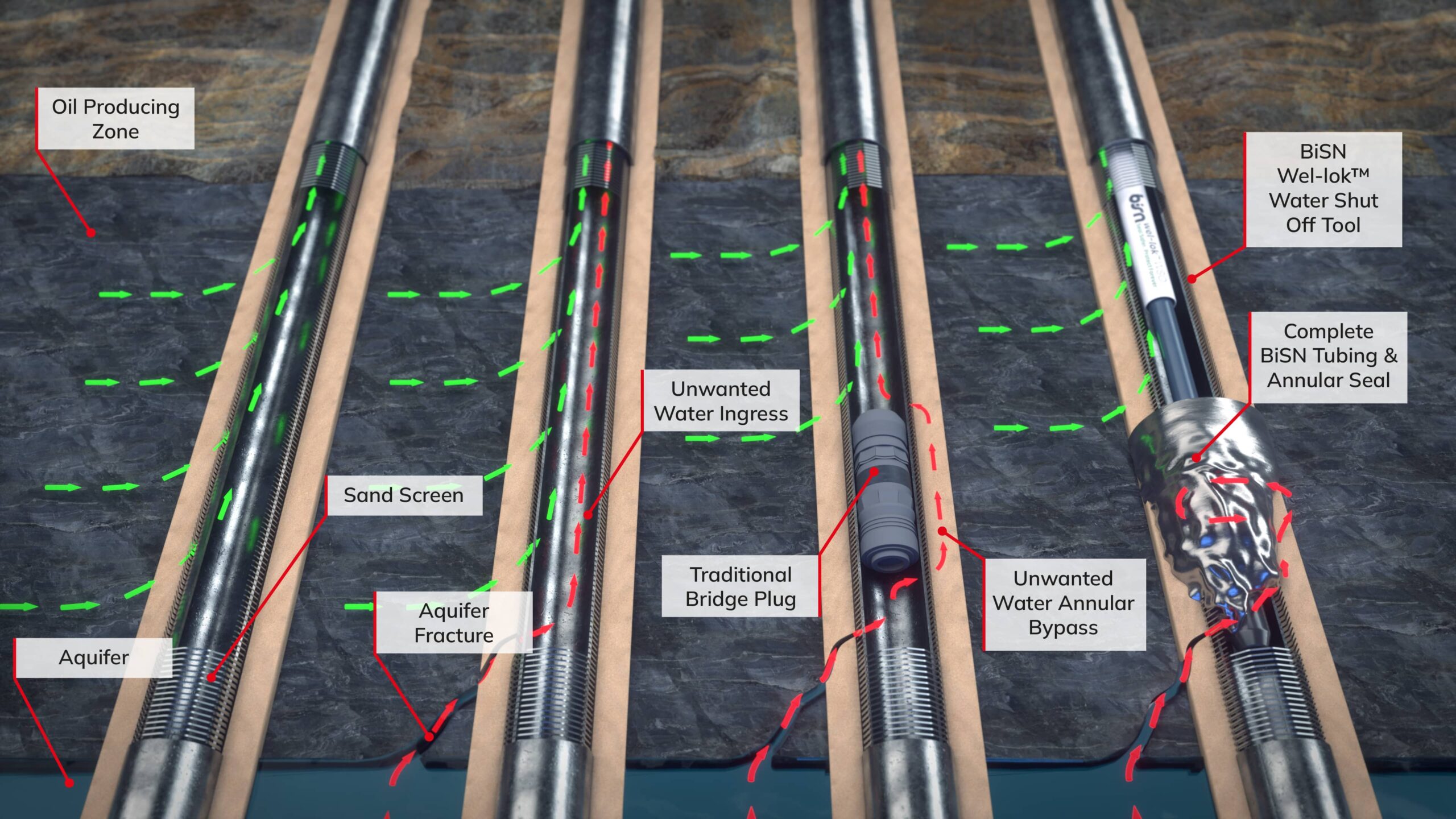

High water cut in operator wells significantly reduces hydrocarbon production and profitability while adding the burden of costly water treatments, disposal, and management.

Unlike traditional methods, wel-lok™ technology provides complete isolation across the wellbore, creating a seal in minutes, ready to set within hours without damaging the screen or completion. This leaves the well ready to be put back on production.

wel-lok™ provides a permanent isolation in a single trip as opposed to other chemical treatments, some of which require multiple applications a year to maintain their effectiveness. The application of wel-lok™ technology can save operators significant cost while increasing production and, therefore, profitability. Unlike any other solution on the market, the wel-lok™ WSO tool seals the annulus and the wellbore in one operation without the need to perforate the completion or squeeze the alloy into the open hole annulus.

Bridge plugs and packers, for example, only isolate inside the completion allowing water to be produced up the annulus. Resins are difficult to place and face curing issues. Gels and polymer flooding take huge amounts of planning and the time to see if the solution has worked can take months.

Suitable for use through screen, gravel pack, slotted liner or perforations and especially effective in OHGP (Open Hole Gravel Pack) and CHFP (Cased Hole FracPack) completions.

The BiSN wel-lok™ WSO solution provides an annular seal without damaging the completion in any way. While other solutions can reduce water cut, perforating or punching holes in the screens is required to gain access to the annulus.

See how wel-lok™ Water Shut Off (WSO) can increase the profitability of your well.

| Deviation | 0 – 82º |

| Pressure | Up to 11,650 PSI |

| Temperature | 50 – 150º C |

| Conveyance | All conveyance methods |

| Restriction | Up to 2.690″ |

| Setting ID | 2.992″ – 8.5″ |

| Sealing ID | 3.598″ – 9.5″ |

wel-lok™ technology is ready to test within hours from deployment.

Decrease water surface treatment by eliminating in the first place.

Ensure profitability from reduced water cut.

Lower the water cut in the production stream.

From rigless deployment to reduced water treatment, lower your carbon footprint.

BiSN wel-lok™ technology has been deployed globally for plug and abandonment, intervention and production enhancement.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies