Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

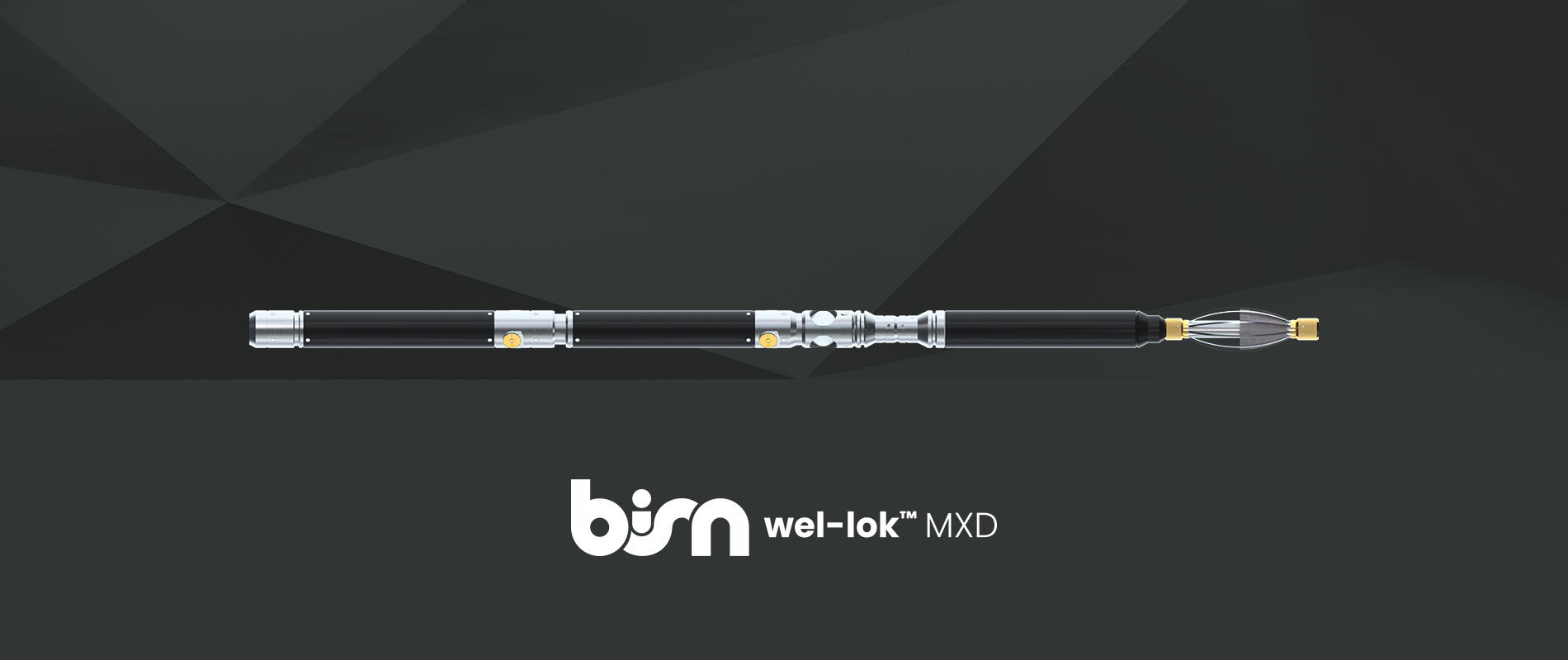

Well Abandonment with wel-lok™ MXD

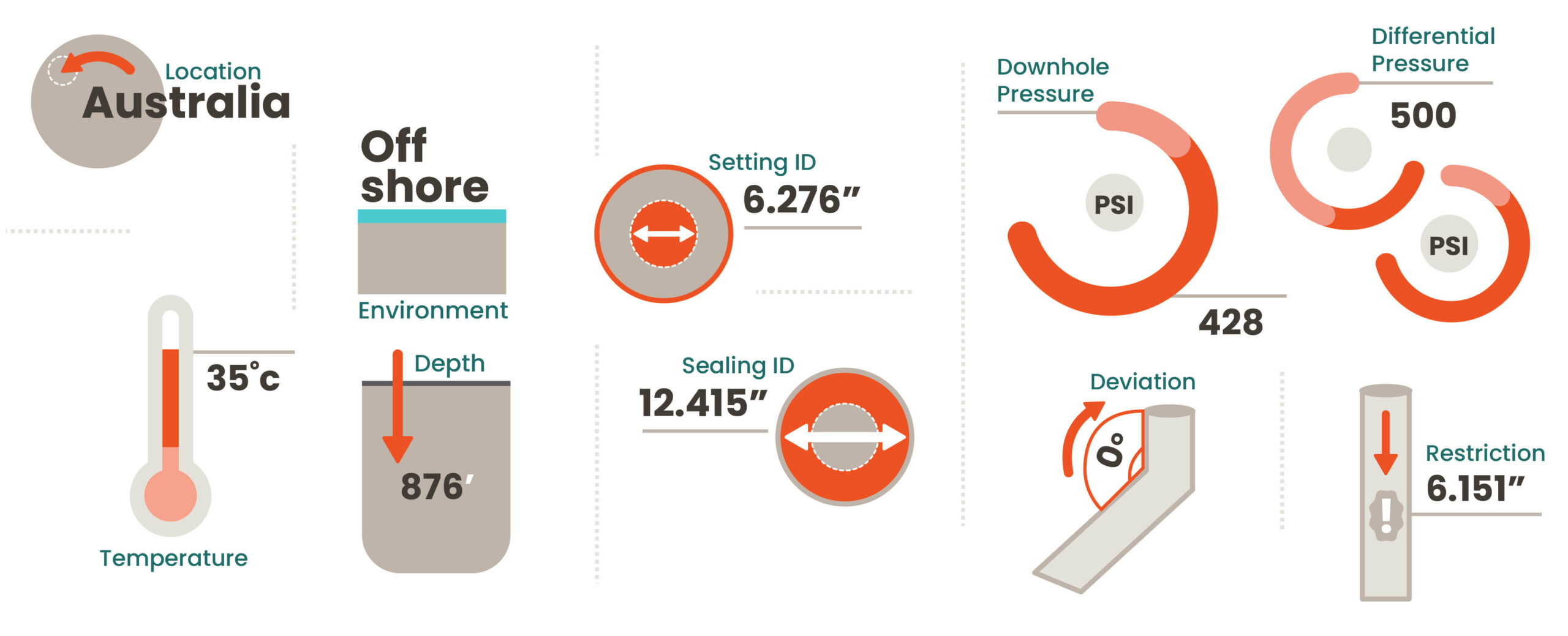

BiSN had been contracted for a 20 well P&A campaign to provide gas tight seals for eliminating gas migration in the annulus between 9 5/8” production casing and 13 3/8” surface casing. One well in this campaign had a different casing program but the same issue. In addition to the 9 5/8” and 13 3/8” casings, this well also had a 7” casing which was cemented in place. This required a tool that could be run inside the 7” casing and seal through a section milled window through the 9 5/8” casing and out to the 13 3/8” casing.

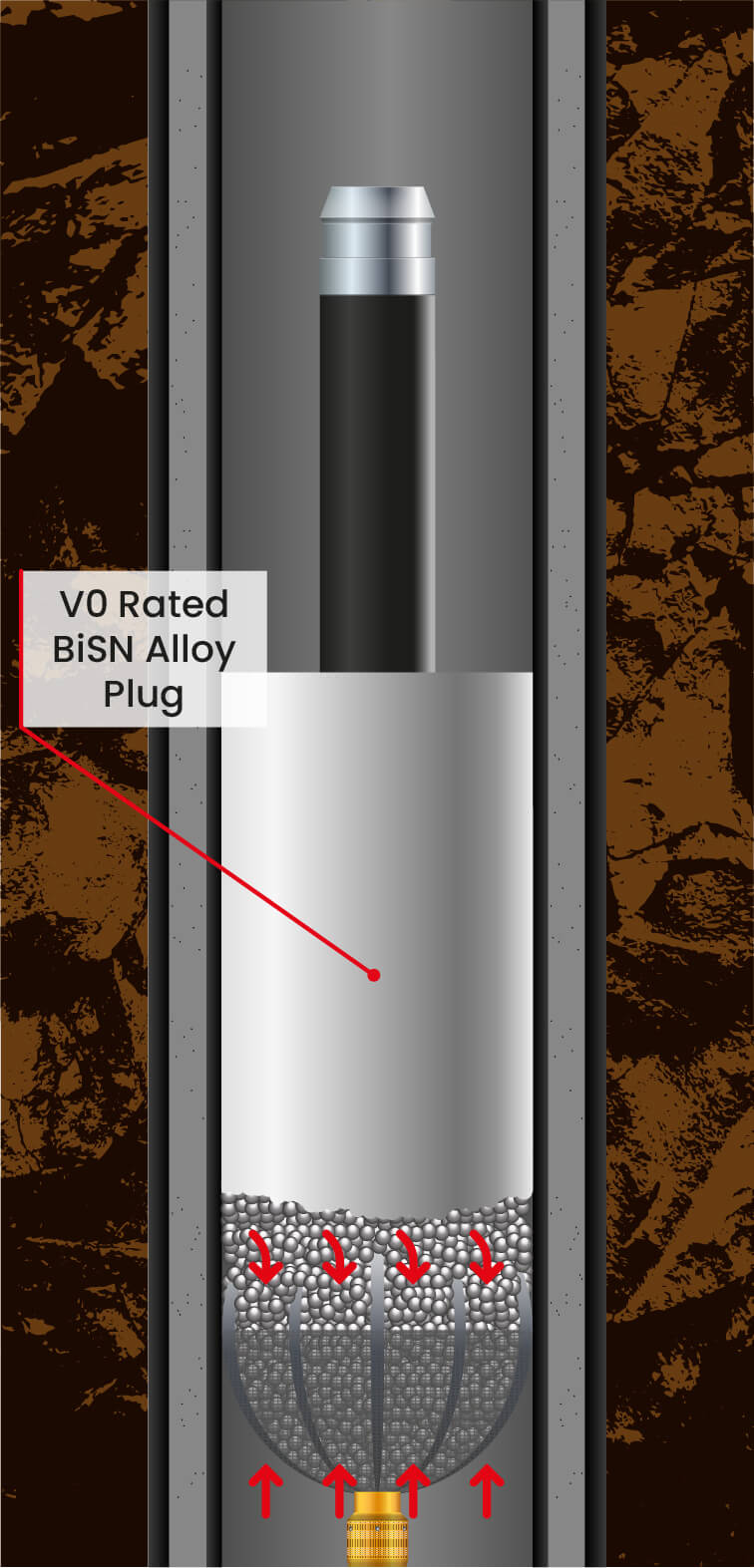

With the 7” casing cemented inside the 9 5/8”, the challenge was to provide a tool with a small enough OD to pass through the 7” casing and provide sufficient alloy to create a gas tight seal out to 13 3/8” casing. The client also required a solid bismuth alloy plug across the wellbore so the modified thermite heater would need to be removed, not left in the center of the plug.

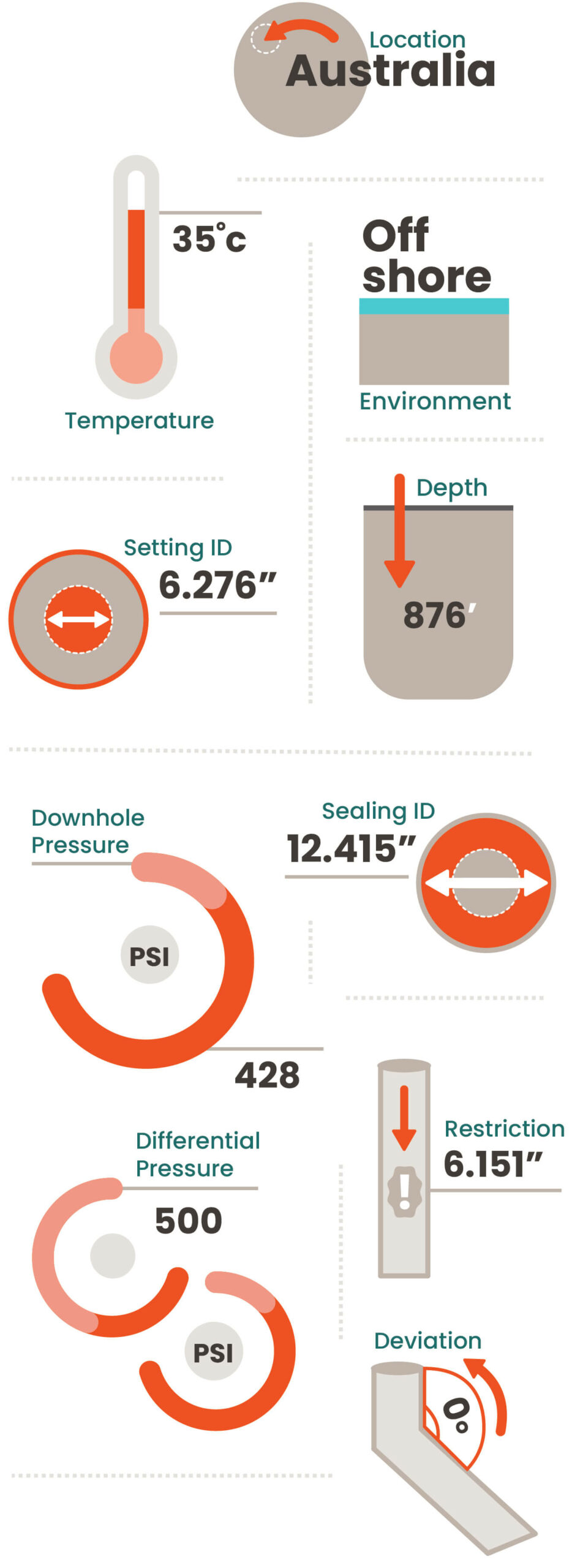

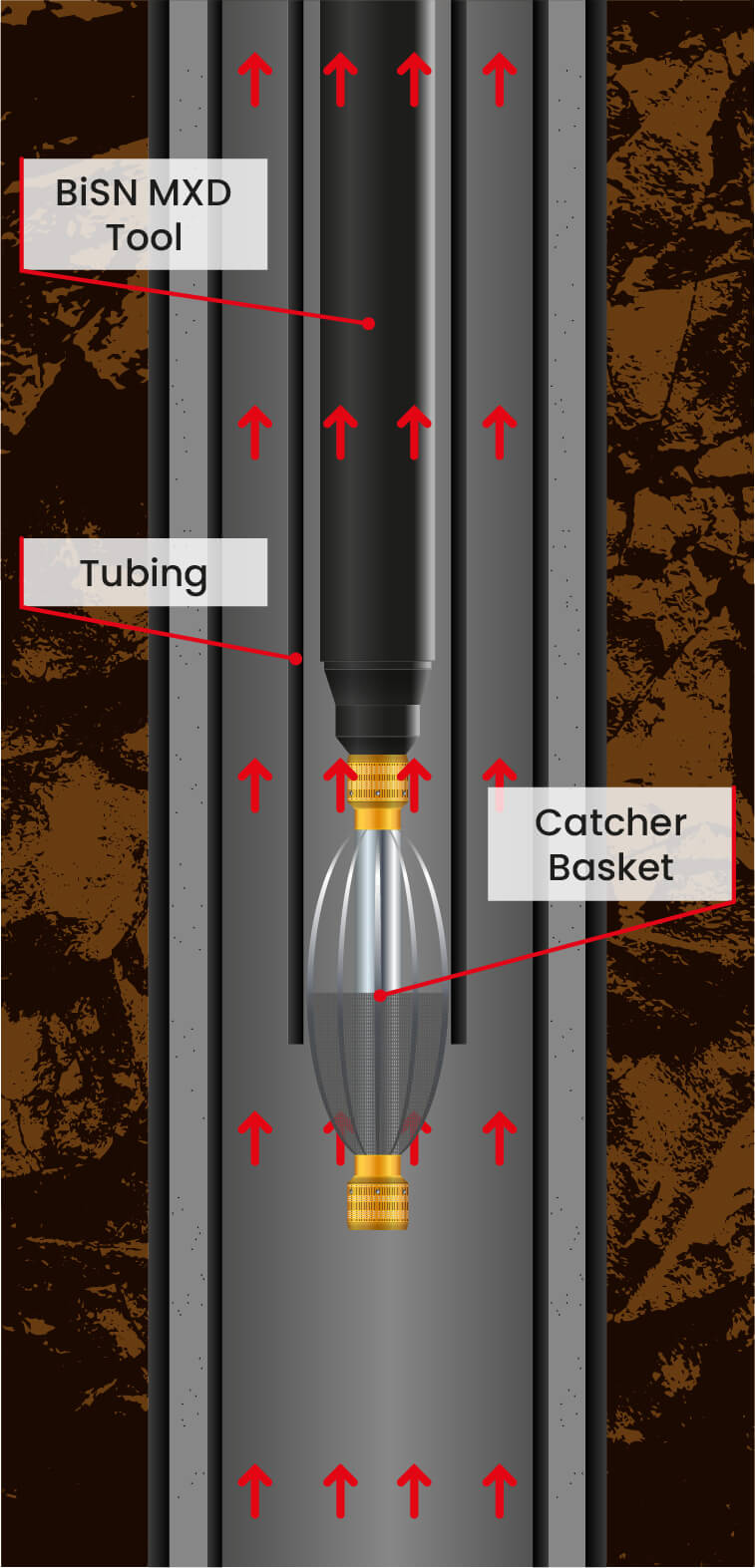

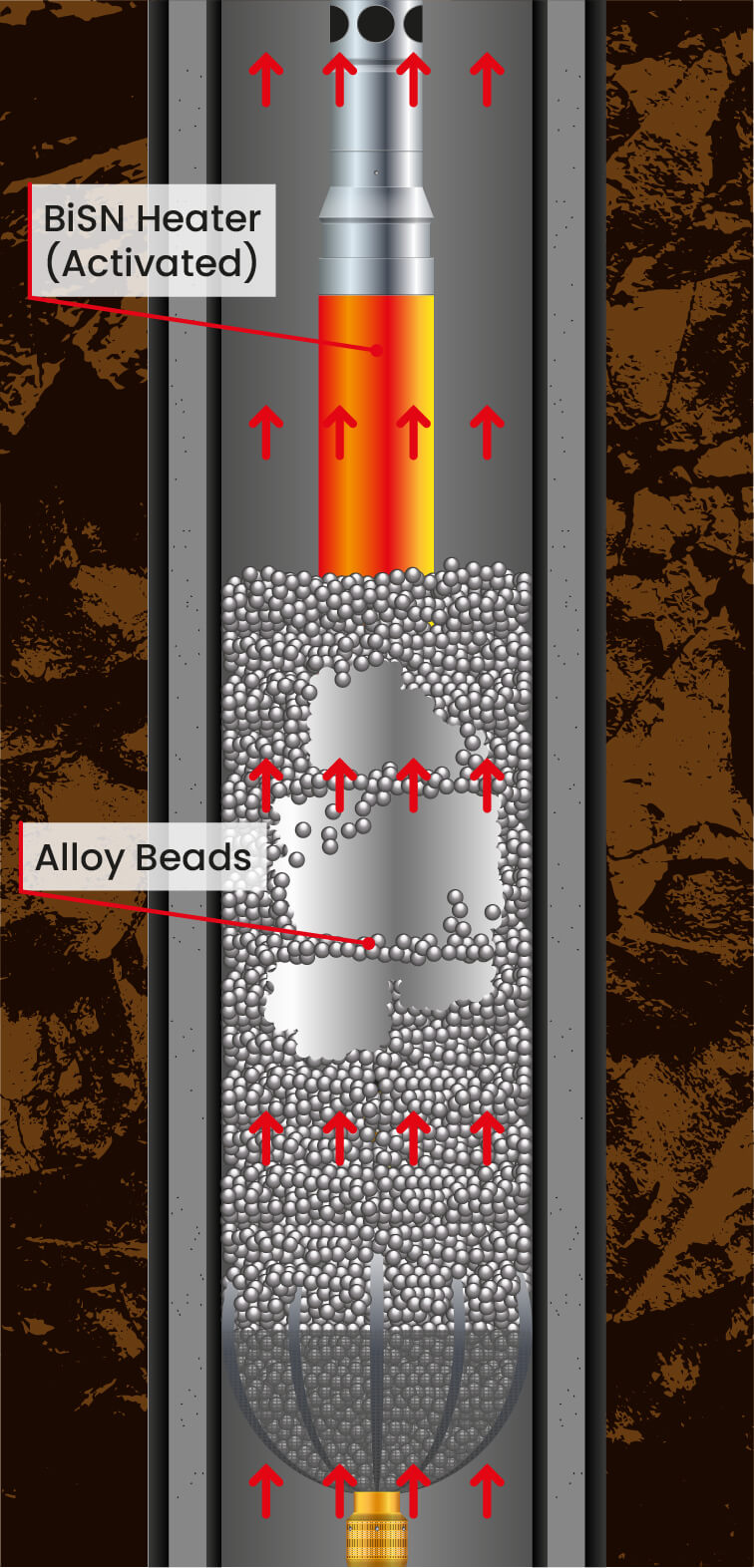

For this well, a window was section milled through 2 strings of casing (7” and 9 5/8”) out to 13 3/8” casing. BiSN deployed a 5.75” OD wel-lok™ MXD that was set across this window. The MXD utilizes bailers to deploy the bismuth alloy in pellet form rather than casting the alloy onto the outside of the heater as other BiSN tools do. This allows for the maximum amount of alloy to be deployed while providing a smaller OD tool.

The wel-lok™ MXD was successfully set and gas migration was eliminated. This well is currently being monitored until all wells on the platform are plugged. This is the largest MXD BiSN has deployed and the first multiple annuli plug.

The wel-lok™ MXD (Maximum Drift) has been specifically developed for rigless through tubing applications. This tool has a smaller OD and higher expansion ratio than some of the other wel-lok™ tools but uses the same technology to create metal to metal seals. Unlike conventional through tubing tools utilising a petal basket and cement or inflatable packers, the MXD™ offers a gas tight seal up with up to a 10,000 psi differential pressure rating and can be deployed in a single trip. Utilising bismuth alloy pellets, deployed inside a bailer, it eliminates restrictions of the volume of alloy that can used to create a seal.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies