Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

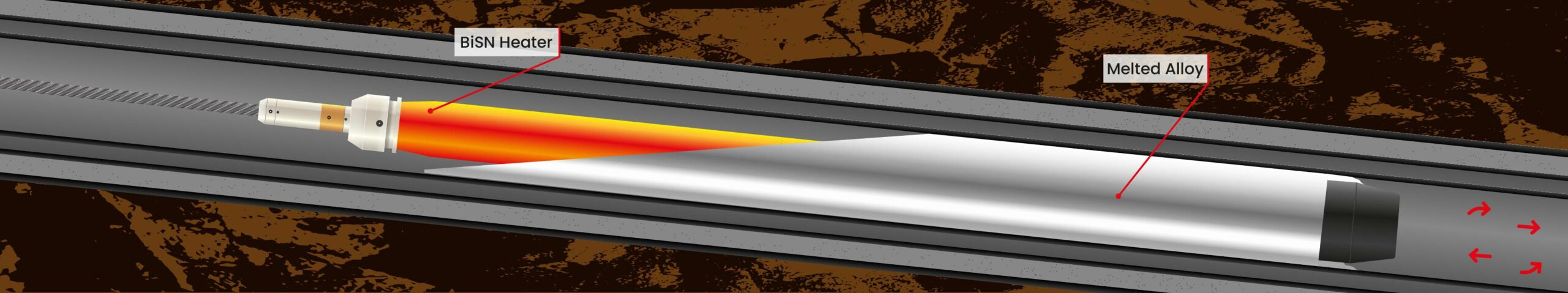

Phase one of a well permanent plug and abandonment, utilising BiSN´s wel-lok™ Tubing Seal tool to seal the 5.5” OD production tubing and isolate the reservoir, in preparation for phase two of the P&A.

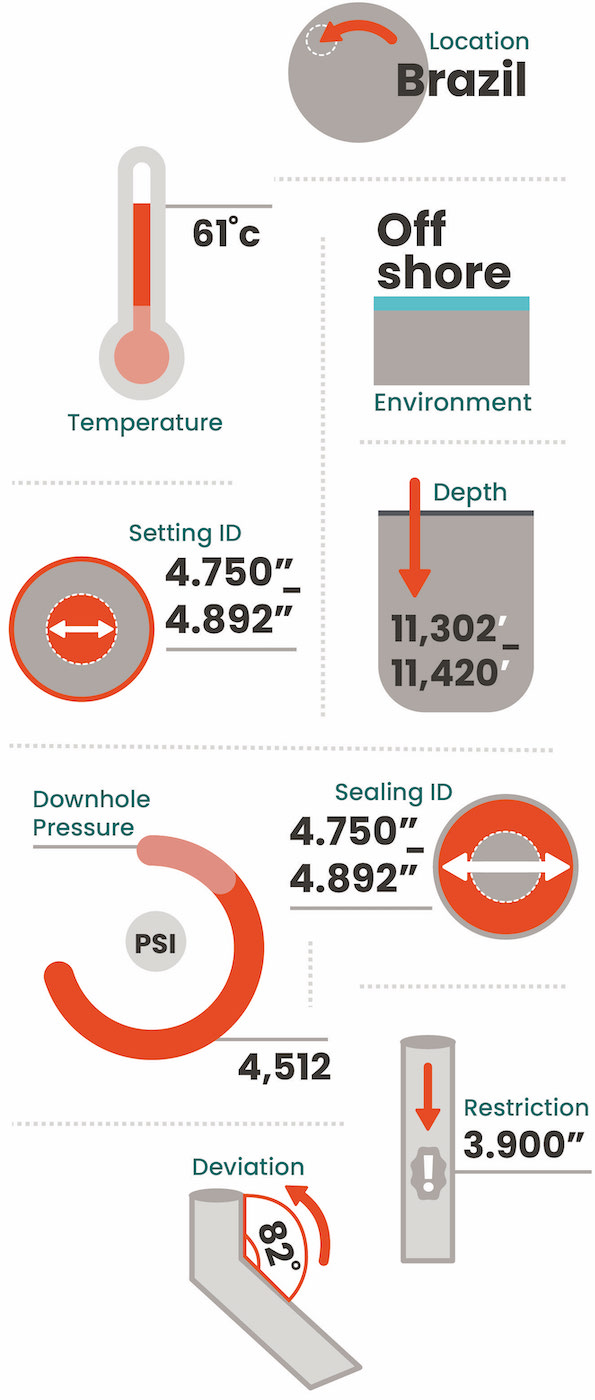

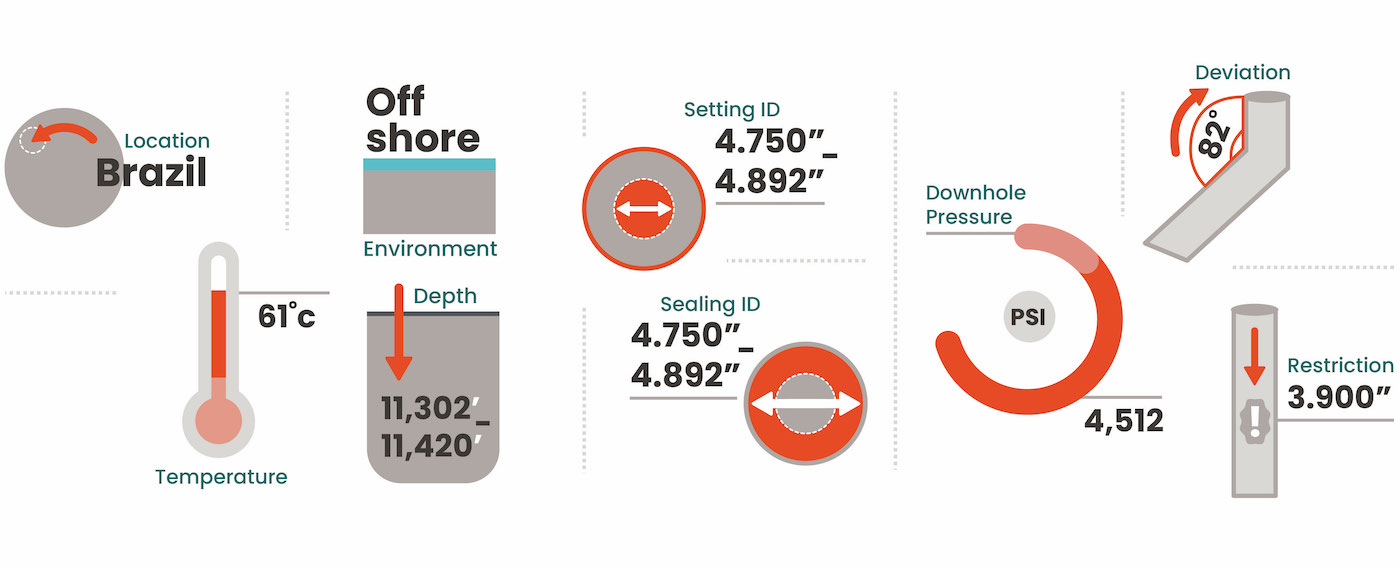

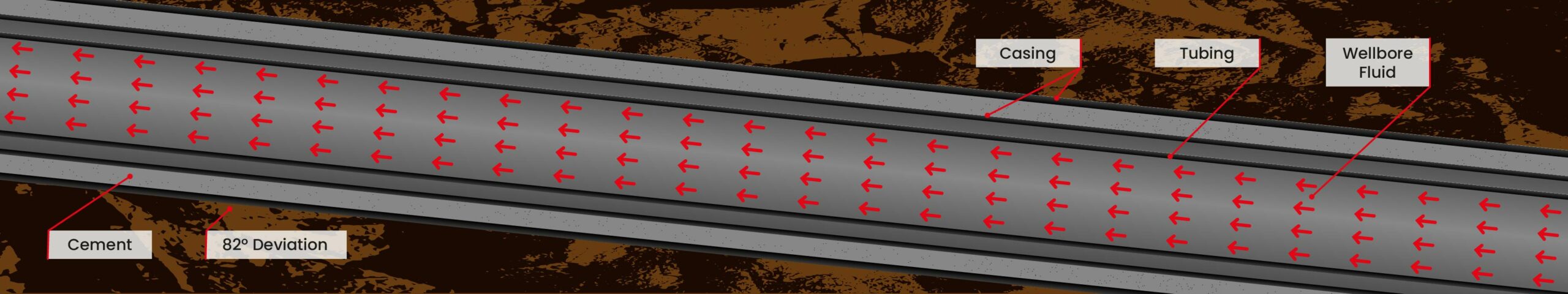

A major operator in Brazil is opting for a more efficient and less costly approach to isolate their production tubing, for either permanent or temporary plug & abandonment interventions – when the valves on the completions fail to operate. BiSN´s wel-lok™ technology meets both of the requirements above, with the addition of offering a high standard gas-tight seal with unique characteristics. This particular well, is a high deviation scenario with a small restriction, where the BiSN tool had be precisely designed for the application.

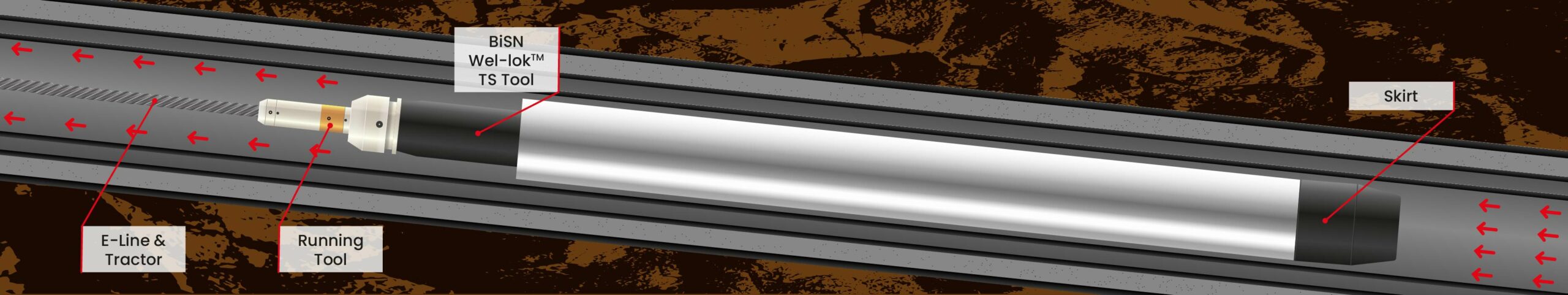

A few challenges were present on this joint deployment. First being the high inclination at the setting depth, which was BiSN´s record deviation on a commercial application. The second challenge was developing a tool that would be able to be run through a small restriction and successfully set inside a tubular without a base below the tool.

The operator expected the well to have the production tubing damaged with corrosion but without running a leak detection log, the precise depth of damage was unknown. For the first run, It was not preferred to set the bismuth plug above the FIV and lose the possibility of using this valve as a barrier option. Due to the concern, the first plug was set below the production packer, incurring on the risk of failing to isolate the production tubing from the reservoir.

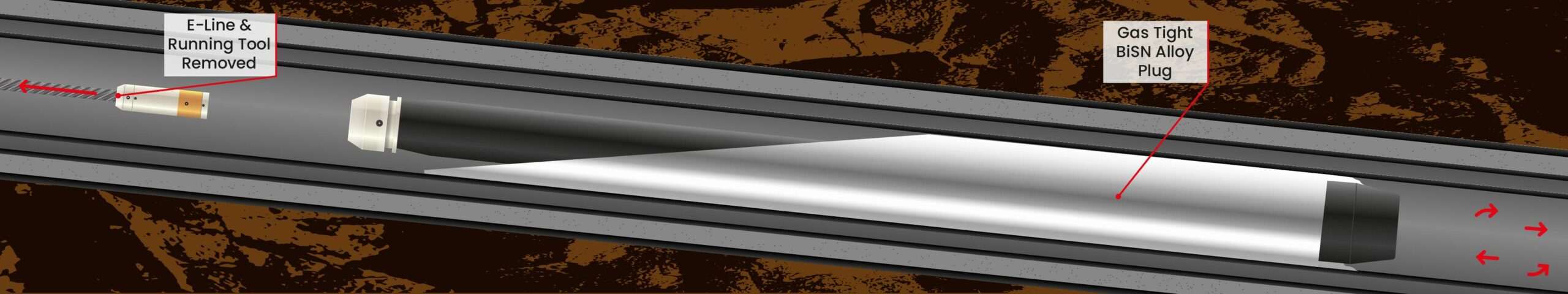

The solution was to create an Alloy-on-Heater tool that was surface activated via e-line power supply. The tool included an alloy retaining assembly at its bottom that was to restrict the molten alloy, thus offering the base to construct the plug above it. Additionally, the BiSN tool incorporated a mechanical shear-sub assembly that was used to shear the toolstring from the heater element, allowing the running tool and electronics to be recovered to surface.

The first plug was successfully set below the production packer, but a failed positive pressure test indicated that the leak was above the production packer. The second tool was run to create an additional seal above the production tubing and the FIV. The second plug was successfully set, and the positive pressure test was successful, indicating the leak in the tubing had been isolated between the bismuth plugs.

Two wel-lok™ Tubing Seal tools were successfully utilized to create a straddle above and below a leaking production tubing string.

BiSN developed a tool and solution capable of creating a seal inside a production tubing with damaged well control and valving devices. This technology opened the door for a major operator, which now has the BiSN technology and bismuth seals, as a new alternative to its panoply of sealing solutions.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies