Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

BiSN’s Wel-Lok™ Seal Through Casing Tool (STC) was successfully used to create an open-hole straddle in this novel application.

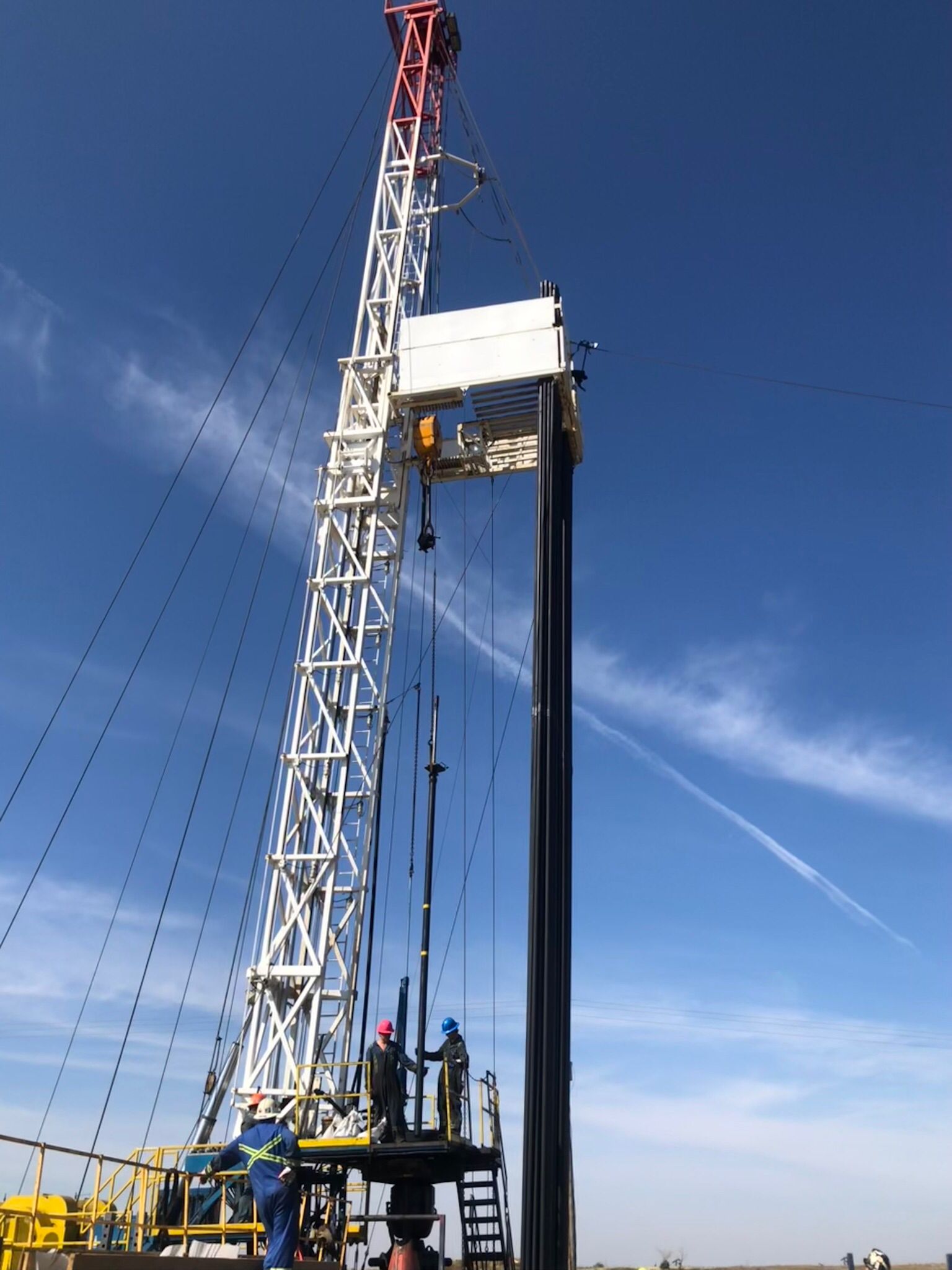

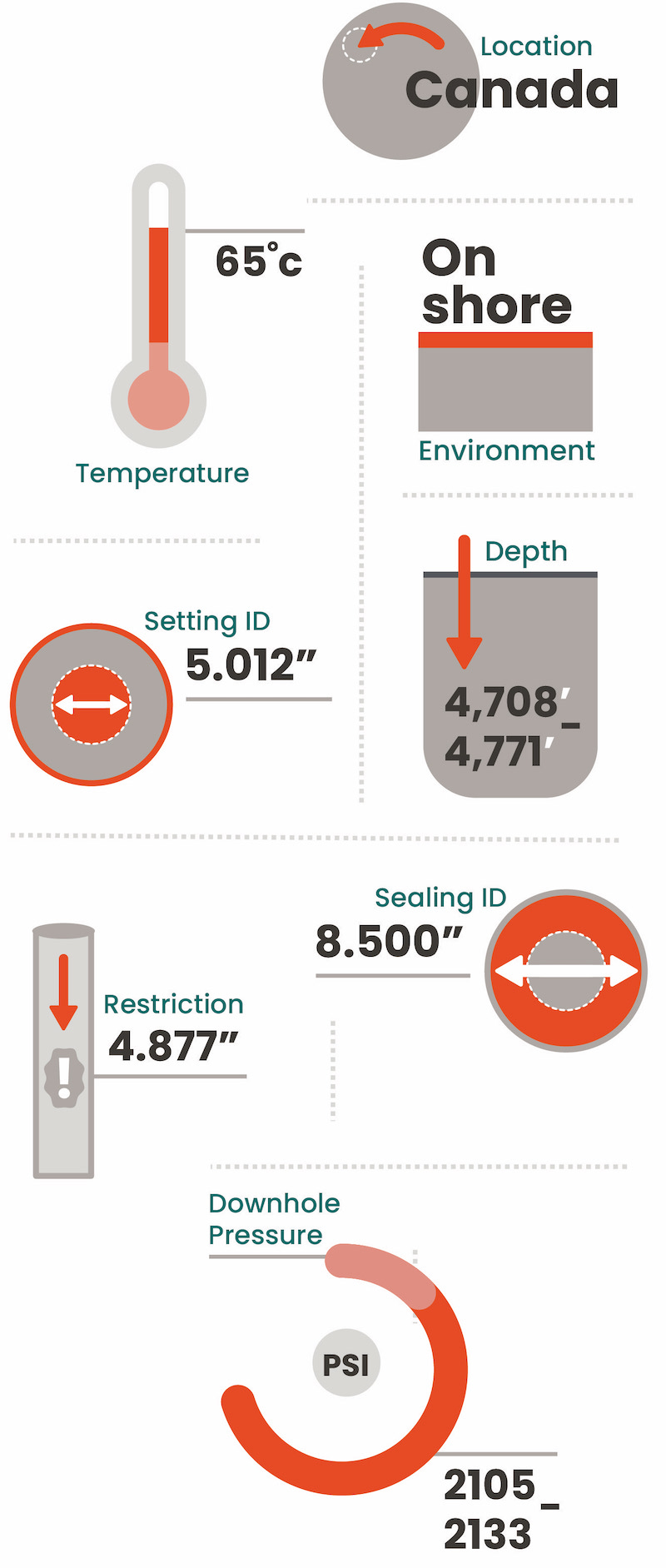

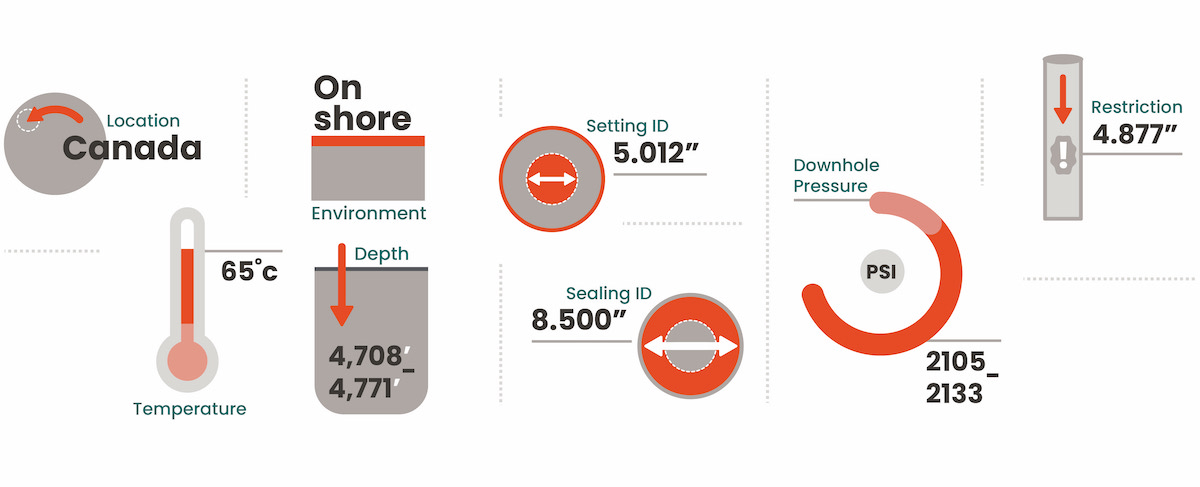

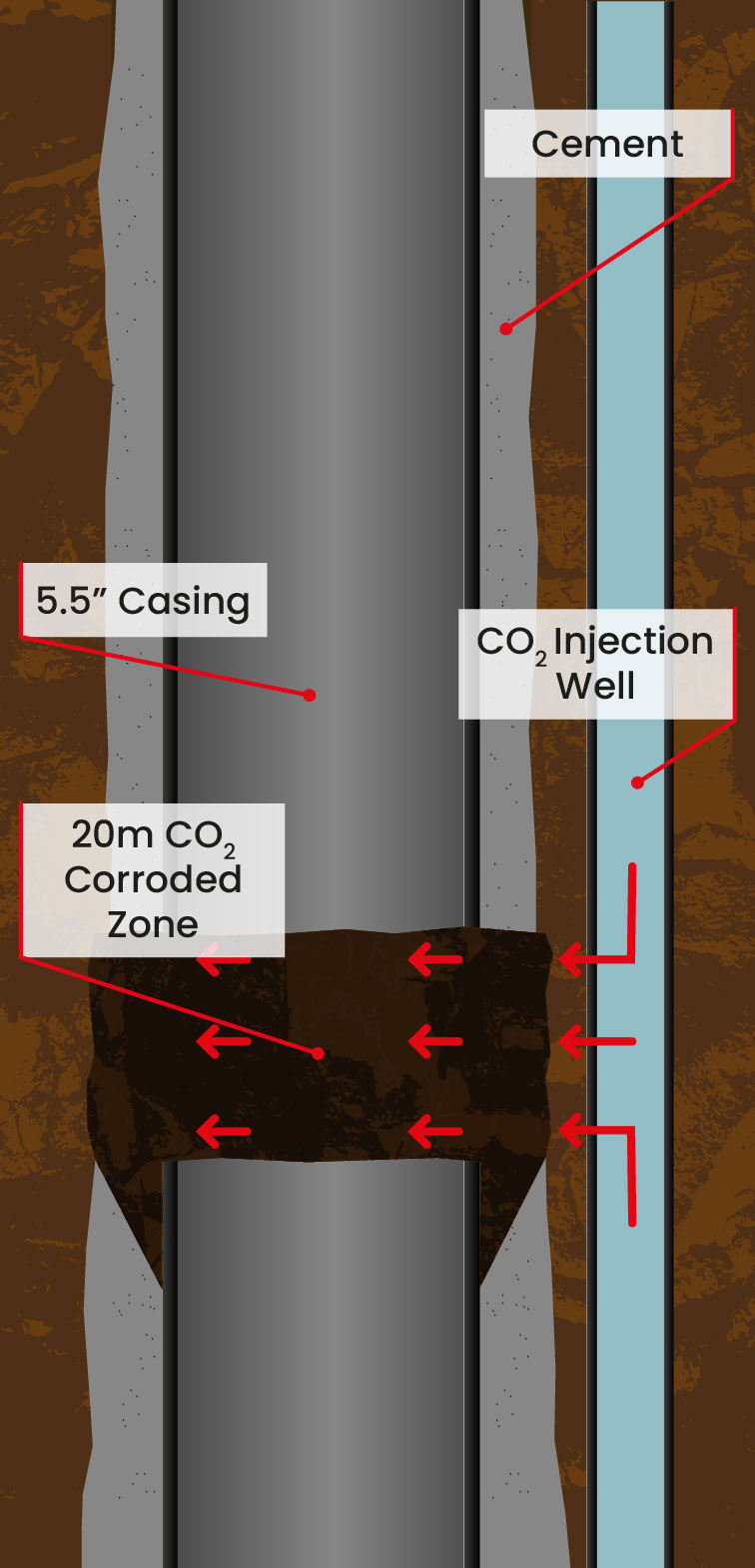

A Canadian operator discovered that an offset CO2 injection well had completely corroded a 20-meter section of 5-1/2” casing on an adjacent well. To plug and abandon the primary wellbore, BiSN was contacted to set a bismuth plug in the open hole at the top and bottom of the CO2 charged lithology. By providing a gas-tight seal above and below the charged strata layer, the well could be isolated from the corrosion source.

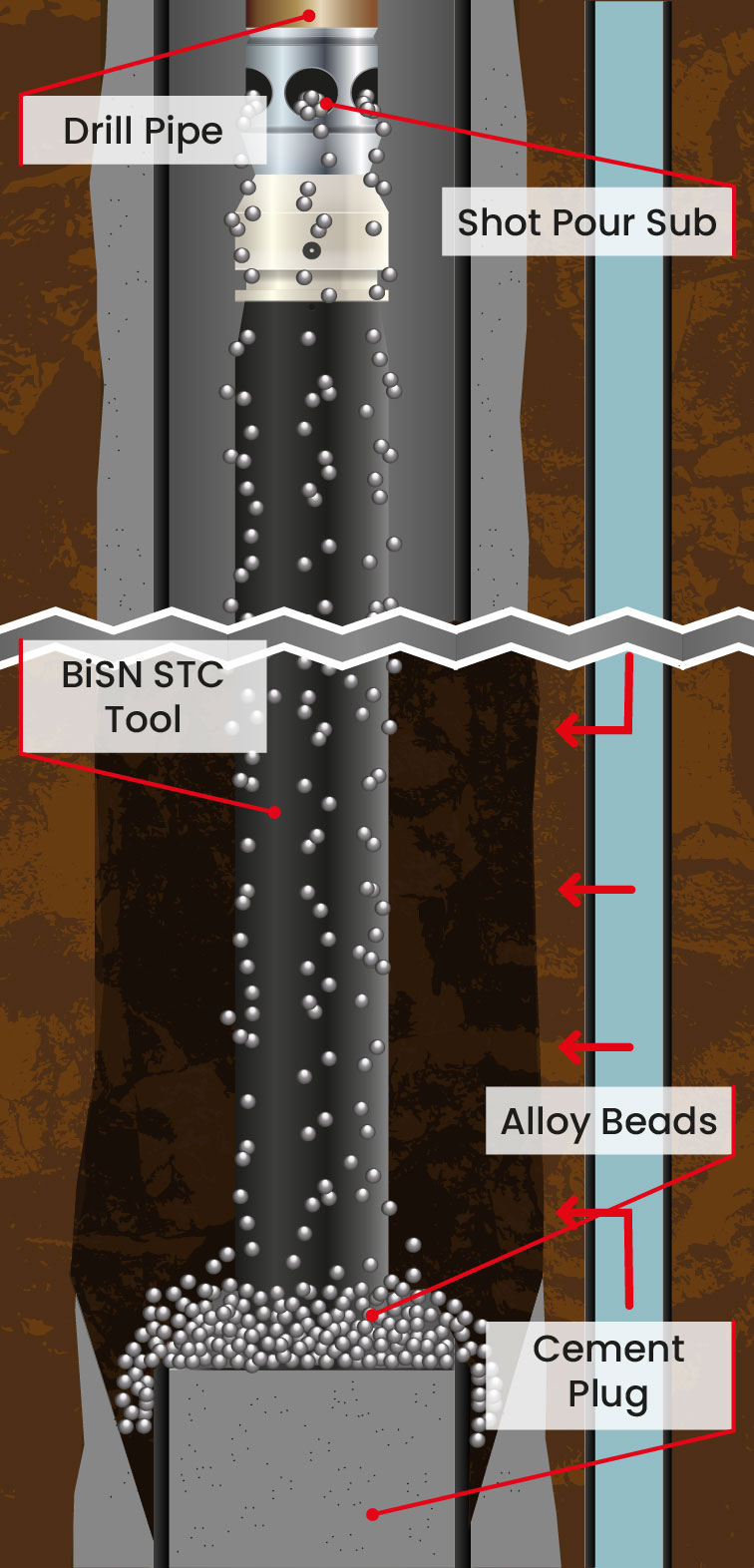

The client did not originally know the extent of the corrosion damage to the 5-1/2” casing. After a successful logging campaign revealed the casing across the target formation had corroded completely, a unique open-hole solution had to be developed. With the open-hole diameter ranging from 5-1/2” to 9”, BiSN proposed a single heater configuration which could successfully be set across the size range. Alloy shot quantity could be adjusted to facilitate precise plug lengths in the different diameters in the field.

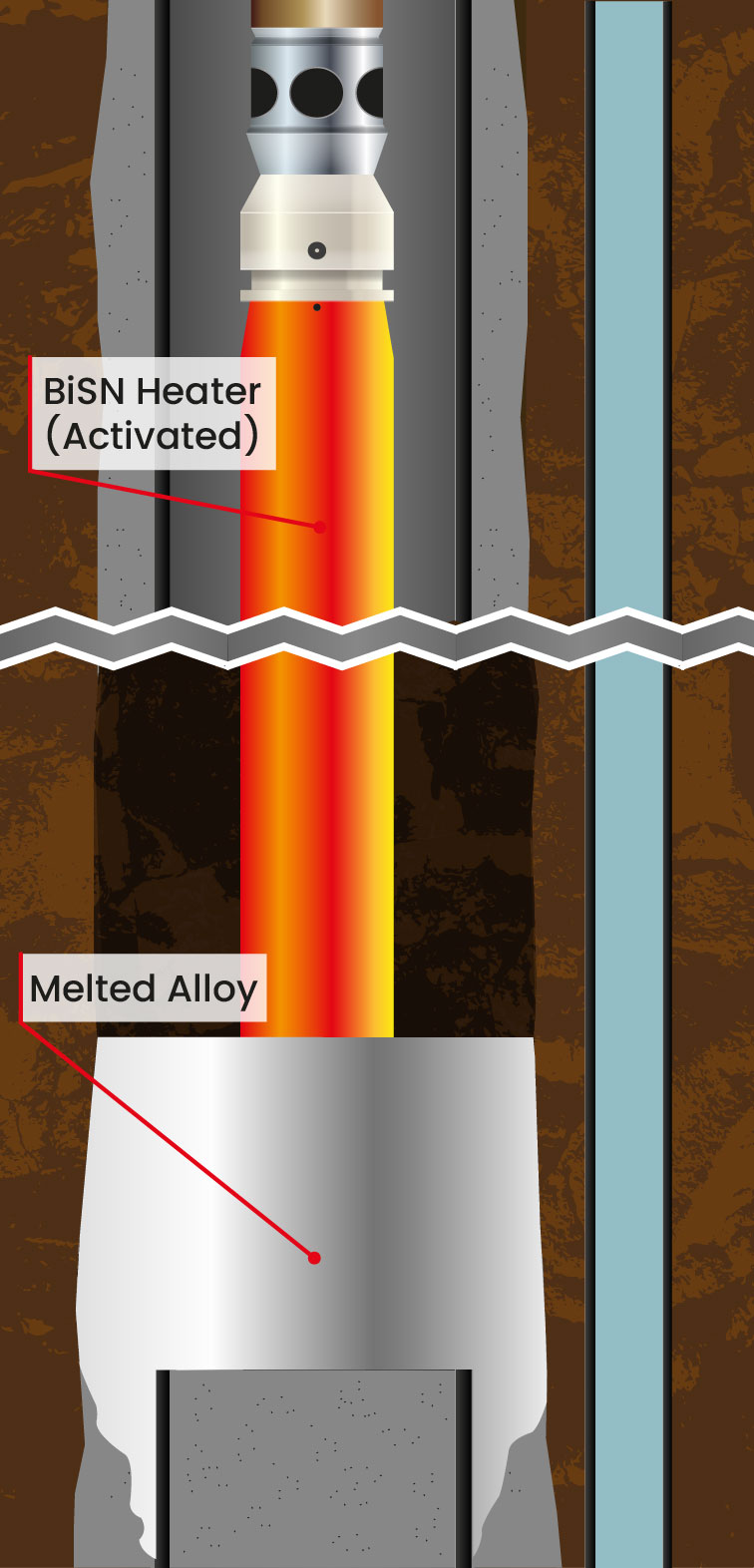

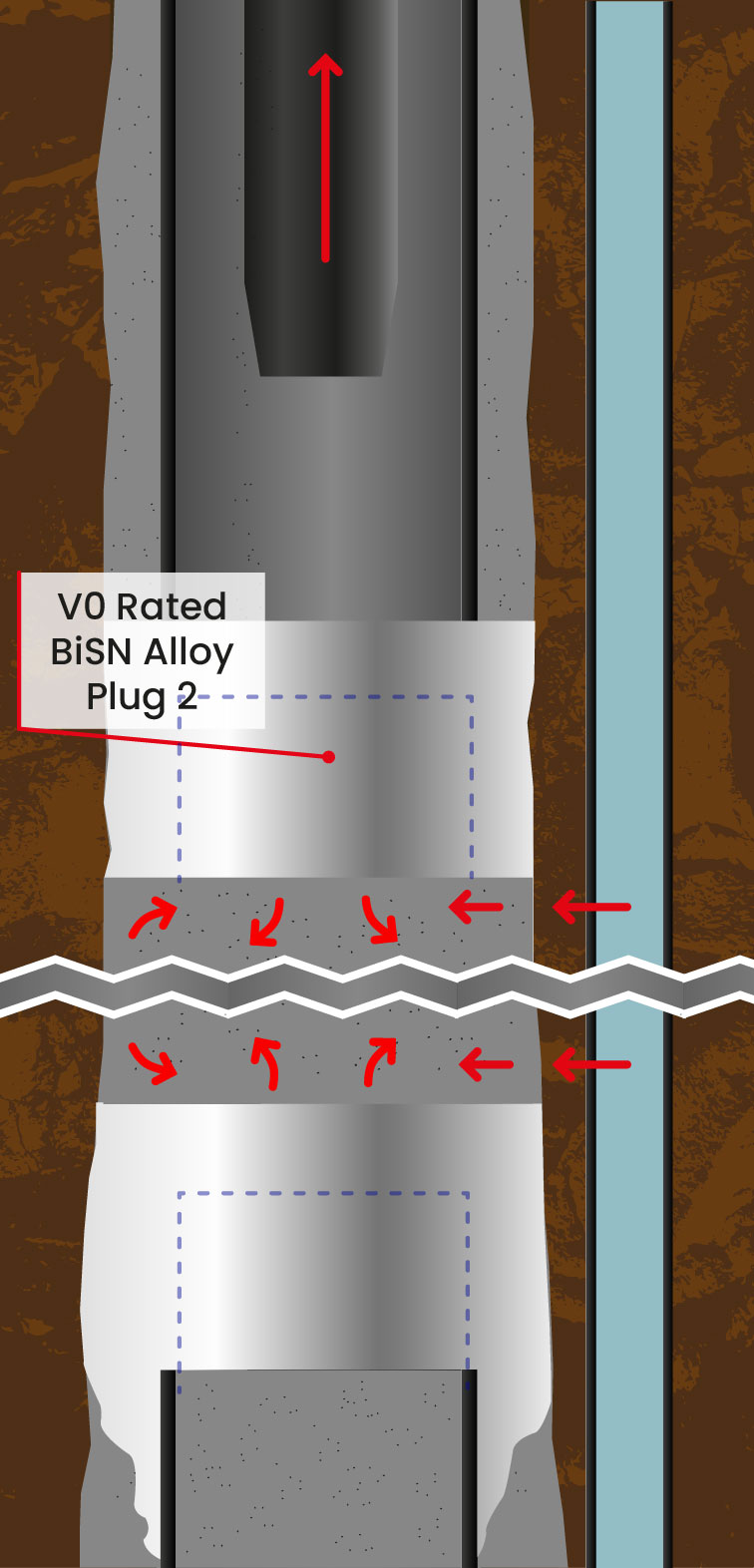

BiSN produced two 4.5” STC heaters which could seal various open-hole diameters that could be encountered. The lower plug utilized a timer activated running tool to successfully melt 400kg of alloy in an 8.5” open-hole, while the upper plug was used to melt 300kg of alloy in a 6.25” open-hole.

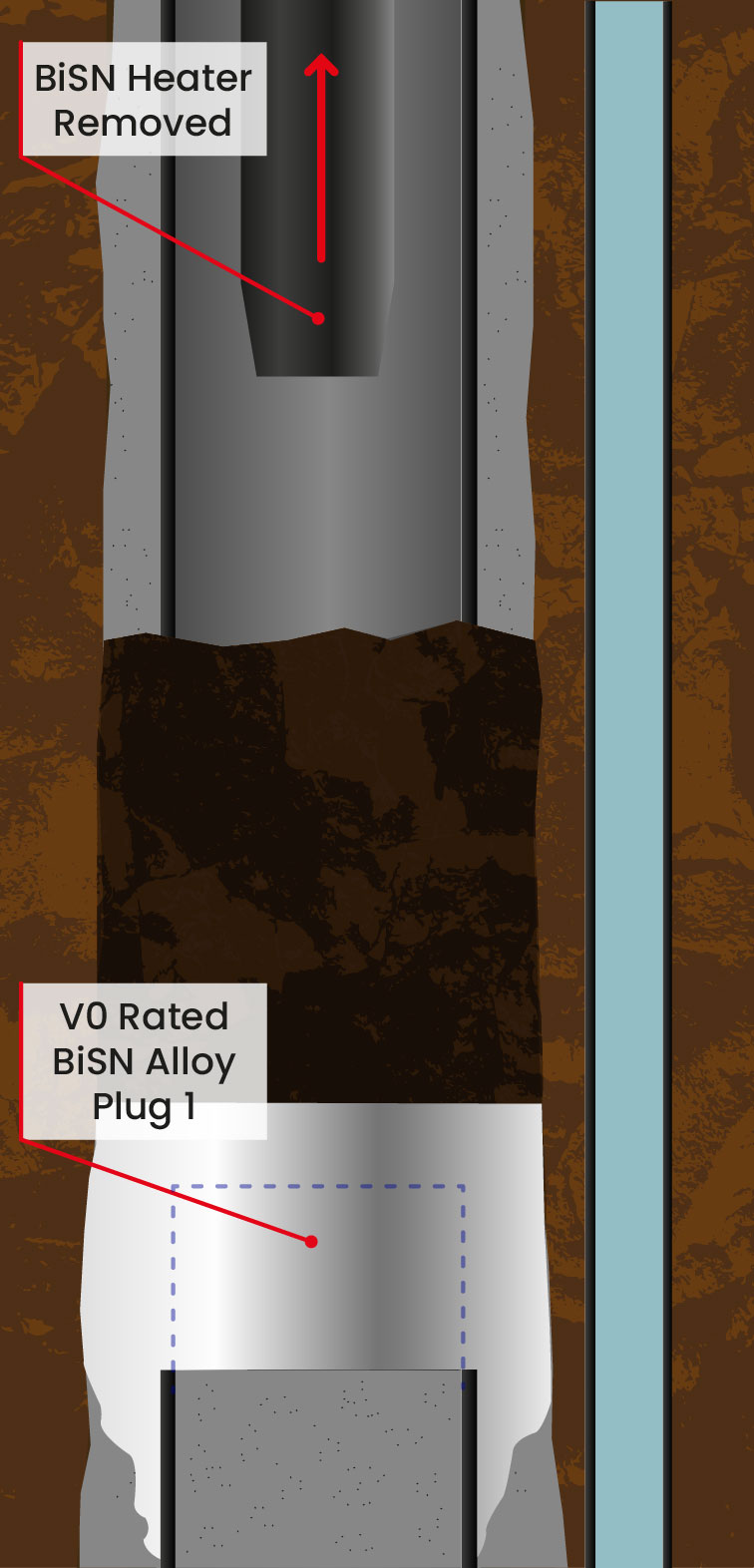

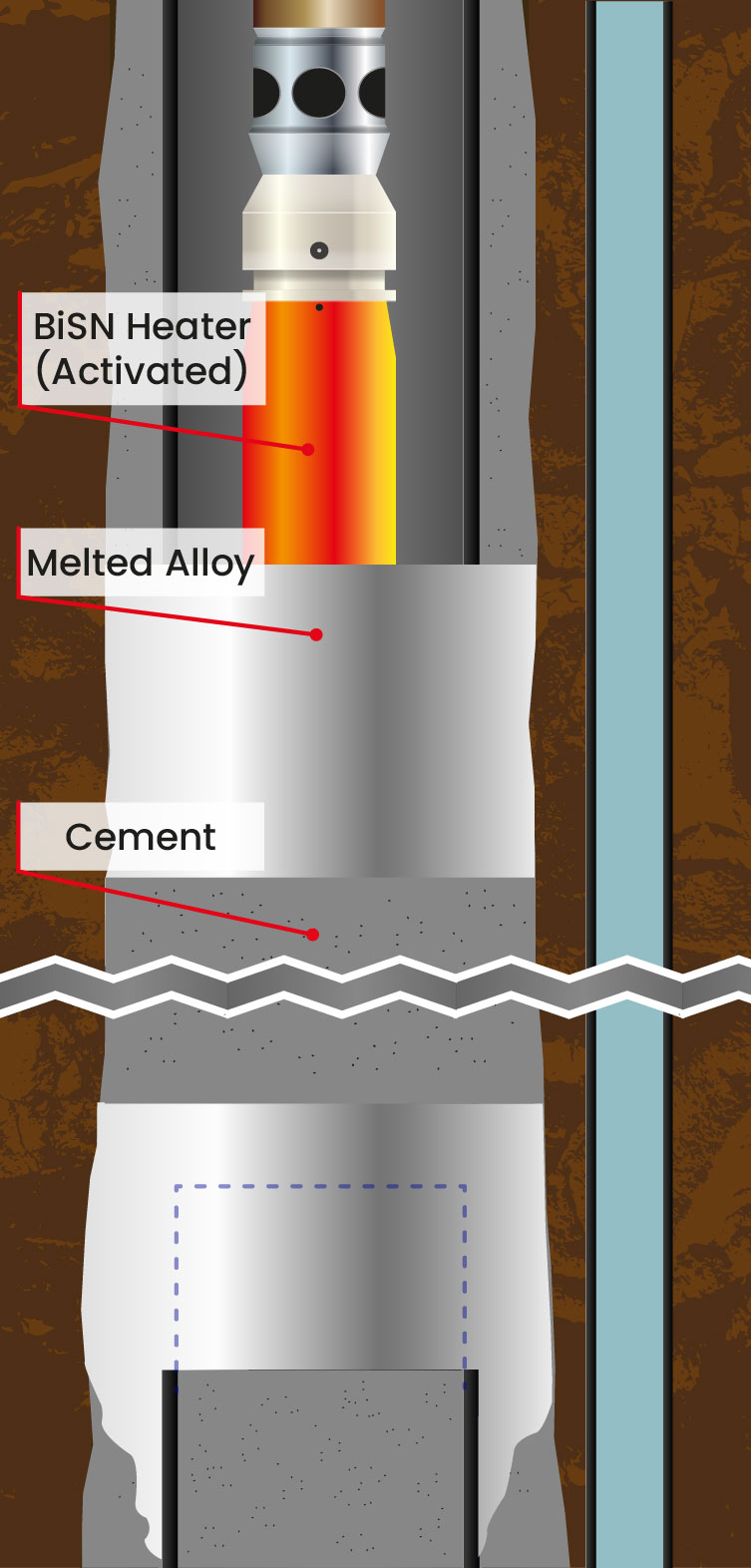

During both operations, the bare heater was run to depth before shot was dropped from surface down the work-string. After exiting through a ported sub, the shot accumulated around the heater until the thermite reaction was initiated. While the alloy was molten, the heater was removed to create a single material barrier in the harsh corrosive environment. A cement plug was spotted between the two alloy plugs to ensure proper space-out of the upper seal. A tag was conducted after each run to confirm the calculated plug height and after the final operation a successful inflow test was performed to verify the work had been successful.

BiSN’s Wel-Lok™ Seal Through Casing Tool (STC) was successfully used to create an open-hole straddle in this novel application.

BiSN developed a novel straddle approach to remediate a complicated barrier restoration. The corrosive properties of CO2 had eliminated sections of the wellbore so it was imperative that the remediation utilized a barrier material that could survive these harsh conditions, while still having the flexibility to set in various sizes of the open-hole. BiSN was able to help the operator reduce HSE risks, costs, and the challenge of returning to this troublesome well in the future.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies