Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

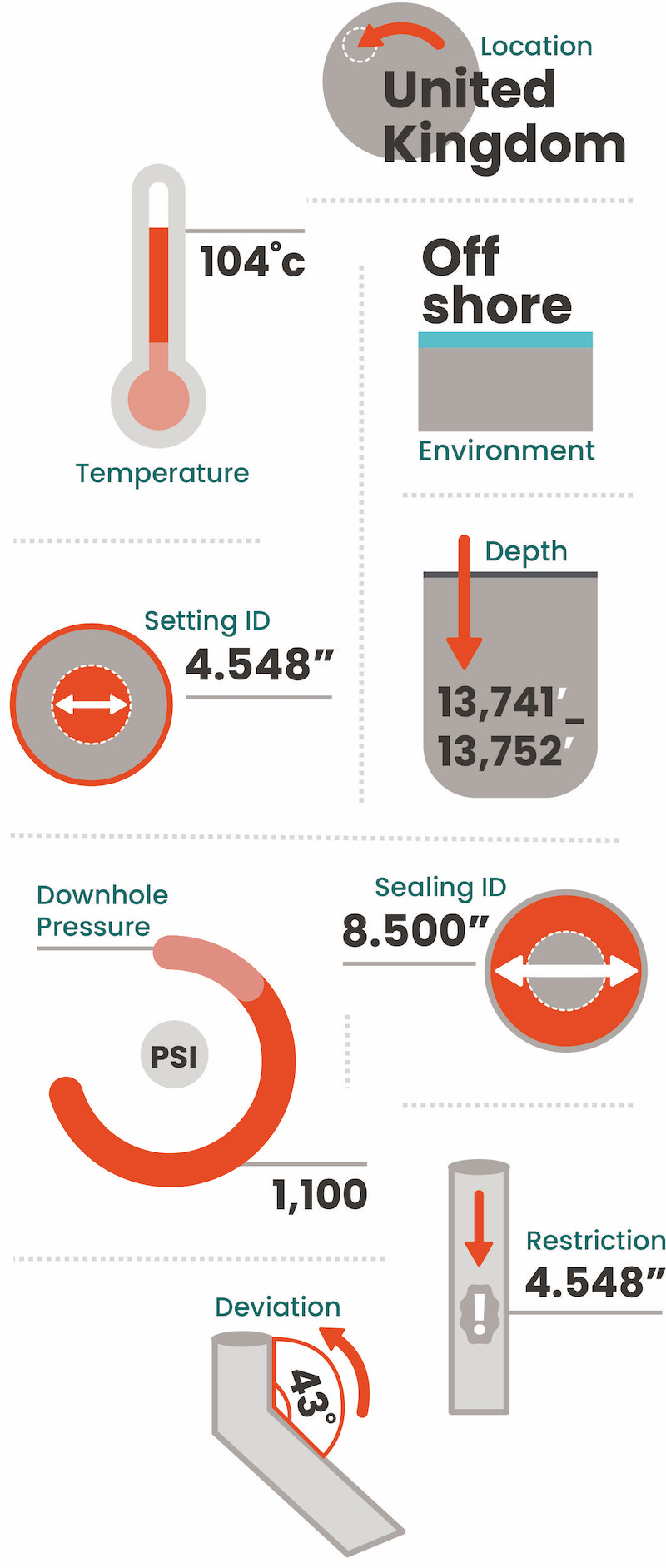

Intervention with dual Water Shut Off (WSO) plugs to isolate a lower production zone behind a cemented liner of a sub-sea well.

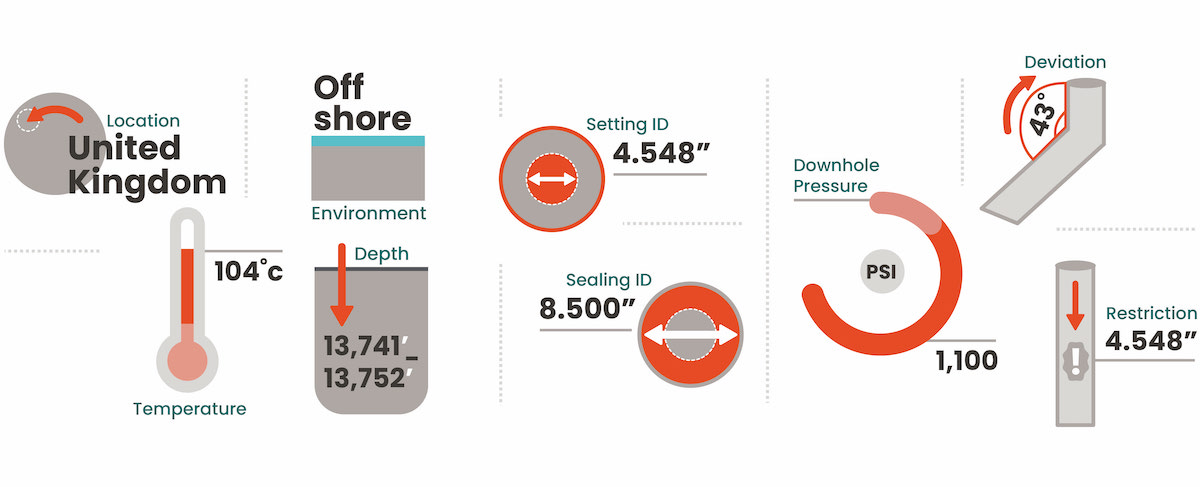

A UK operator was experiencing increased water production from the lower zone in a sub-sea well. This lower zone had previously been isolated via a bridge plug set inside the production liner. Subsequent logging operations indicated that the water was coming via the annulus behind the liner, presumably because of poor/damaged cement. By providing a gas-tight seal through the liner via perforations, the lower sands could successfully be isolated from the rest of the wellbore.

There were multiple challenges unique to this deployment which necessitated careful planning and contingency considerations. On the execution front, the work needed to be done utilizing a riserless light-well intervention vessel (LWIV) on the subsea well. This type of work is very sensitive to weather and commonly involves multiple service providers collaborating on wireline runs that can last several days in harsh environments. Meticulous SIT’s must be carried out well in advance to make sure BHA’s are properly configured to allow all the components to be successfully integrated.

On the tool design process, the LWIV execution meant we were constrained on the total length and weight of the proposed tool string. Adding more complexity was the unknown cement condition behind the production liner. Our proposed sealing solution needed to be flexible enough to provide zonal isolation of the annulus with cement coverage ranging from full-coverage to free-pipe conditions.

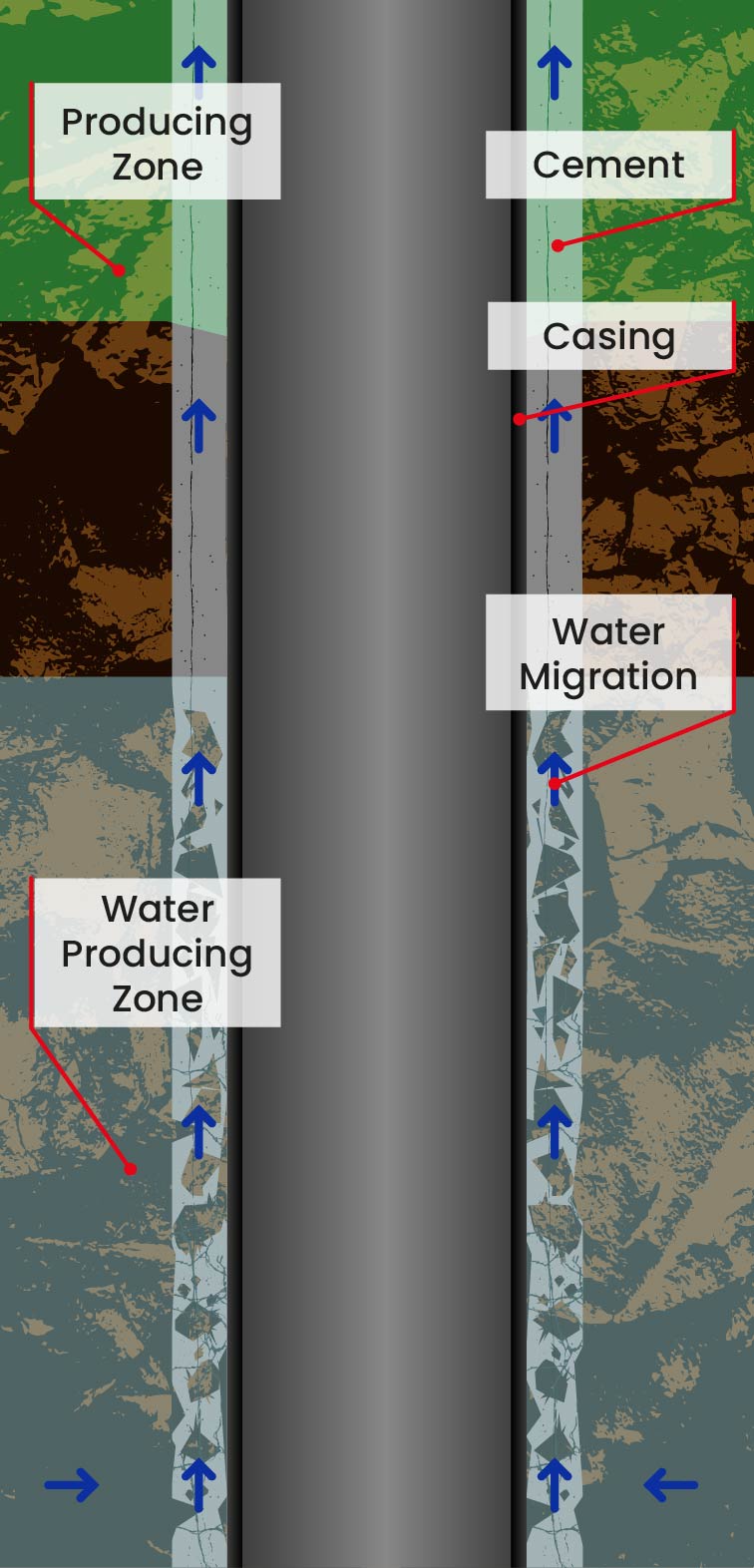

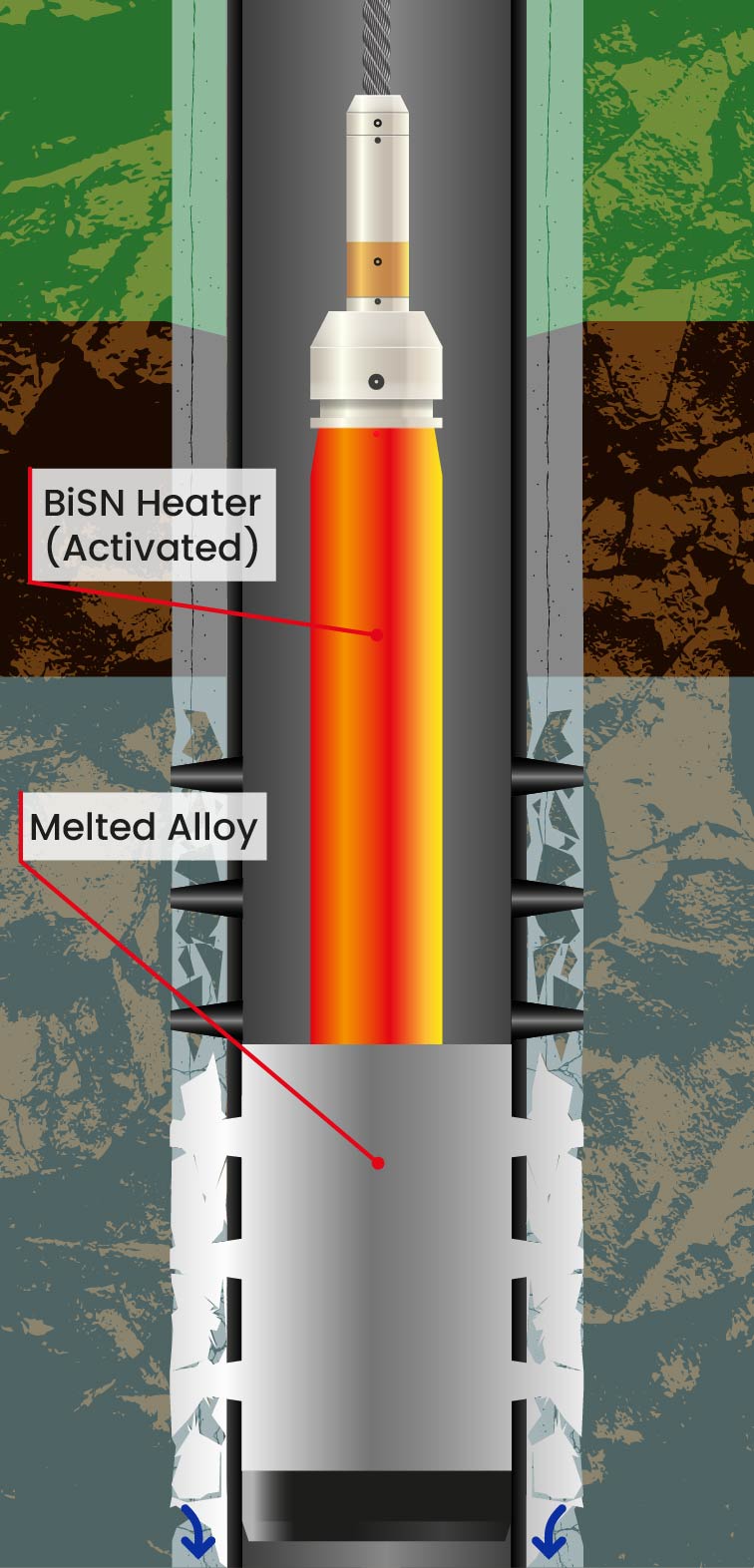

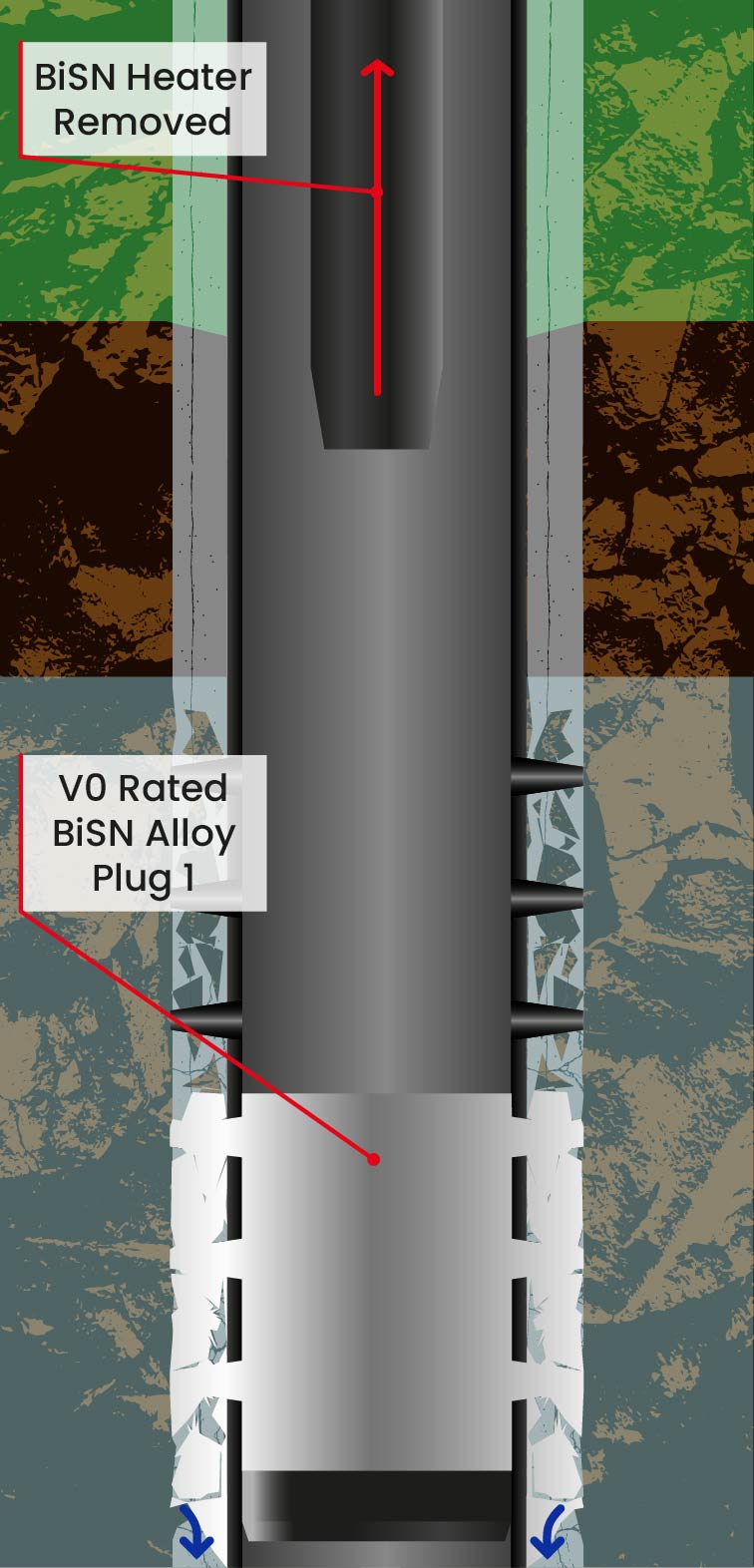

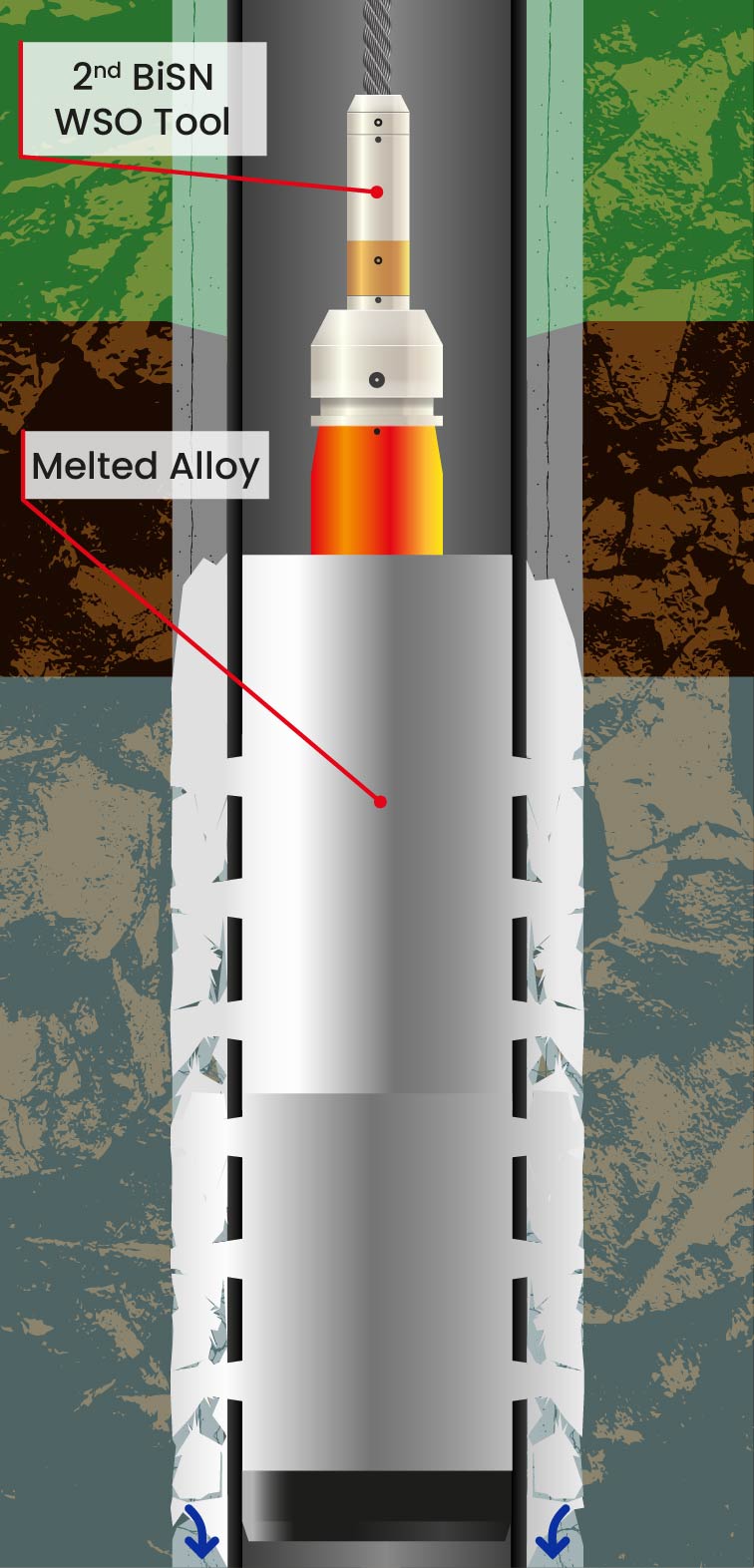

To gain access to the annulus, a perforation program was designed to allow sufficient flow area for the bismuth alloy through the cemented liner while ensuring the perforated length would be sealed after the operations with alloy. Due to the unknown but likely poor content of the cement in the annulus at the setting depth, it was possible that a dual plug system would be required whereby the first WSO tool would be deployed to provide a base plug inside the completion and the annulus. Depending on percentage of fill in the annulus, a second WSO tool had to be deployable to create a longer effective seal on top of the first.

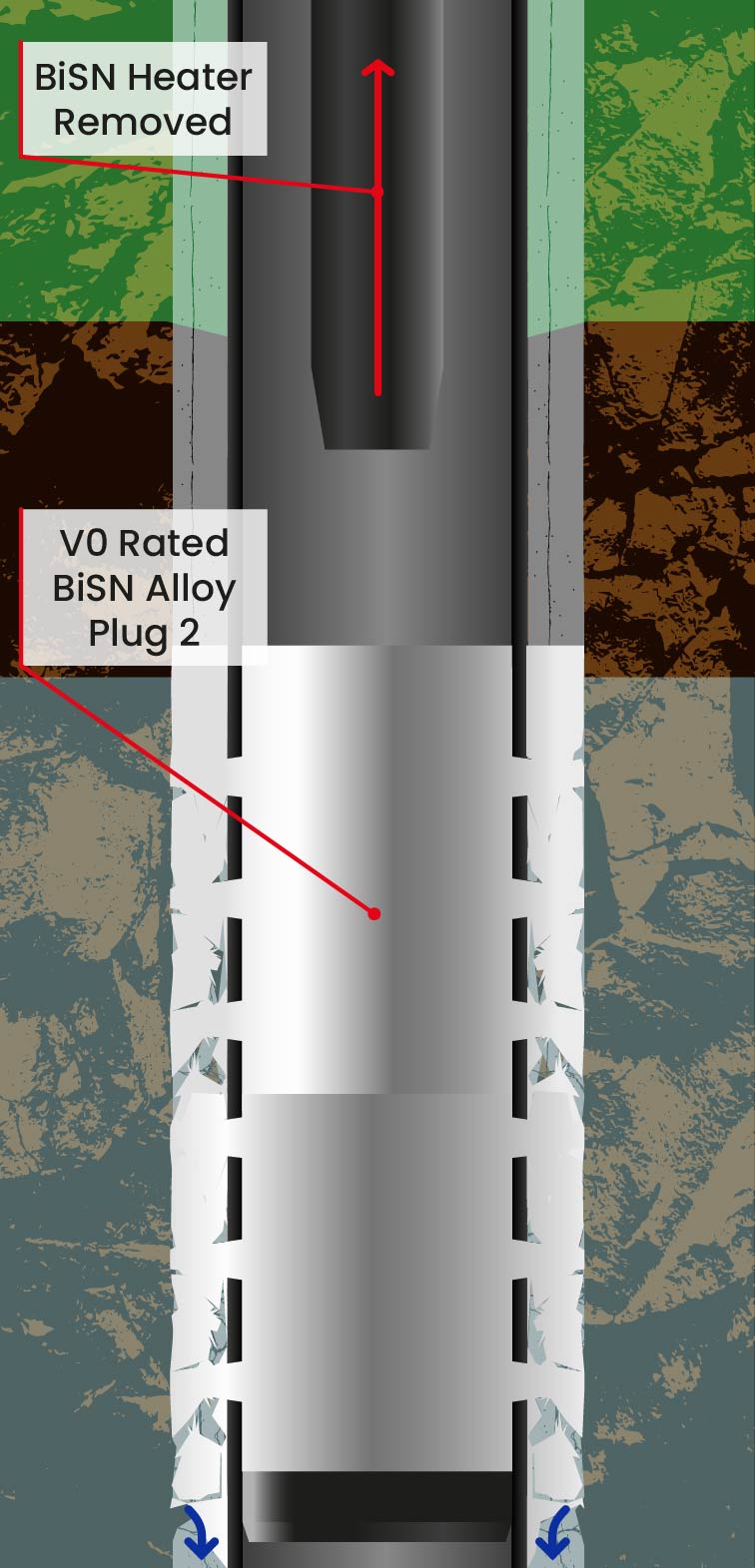

The design of such a WSO solution for this well required the heater to be retrieved to allow for the option of a secondary tool to be run. Furthermore, retrieval of the heaters would allow for a confirmatory tag of the alloy plug and estimation of the annular cement coverage. The additional benefit of removing the heater allows for the production interval directly above the isolated zone to be produced without flow restrictions in the liner itself.

BiSN designed and produced two 4” OD WSO tools which in combination could seal out to the 8.5” open-hole diameter with annular cement coverage ranging from 0%-100%. The 8m tools were each designed to carry and melt 250kg of BiSN alloy and activated via electrical signal from the wireline.

Two BiSN Wel-Lok Water Shut Off Tools (WSO) were successfully set to create a zonal isolation of the lower sand once it was determined that continuous water production had created significant washout of the annular cement. After the well was brought back online, water production subsequently dropped by over 80% which allowed for increased oil production and drawdown of the upper sands within the reservoir.

BiSN developed a novel intervention solution to accomplish zonal isolation in unknown annular conditions. BiSN was able to help the operator execute a successful intervention campaign which restored production in a well that had previously been plagued by unwanted water production of a lower sand.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies