Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

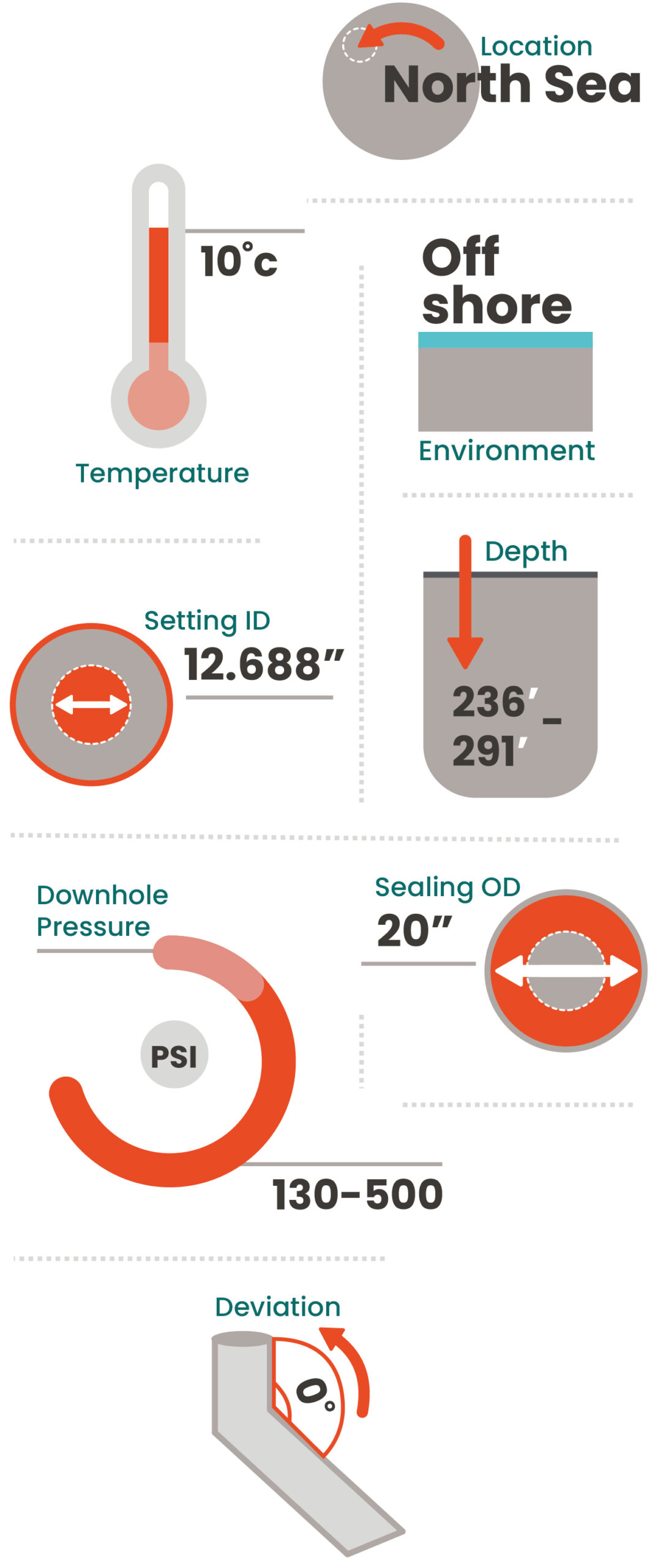

BiSN recently worked with a supermajor on a multi-well Plug & Abandonment campaign in the UK North Sea setting a series of wel-lok™ plugs to stem the flow of gas to surface allowing for the wells to be permanently abandoned in a safe condition.

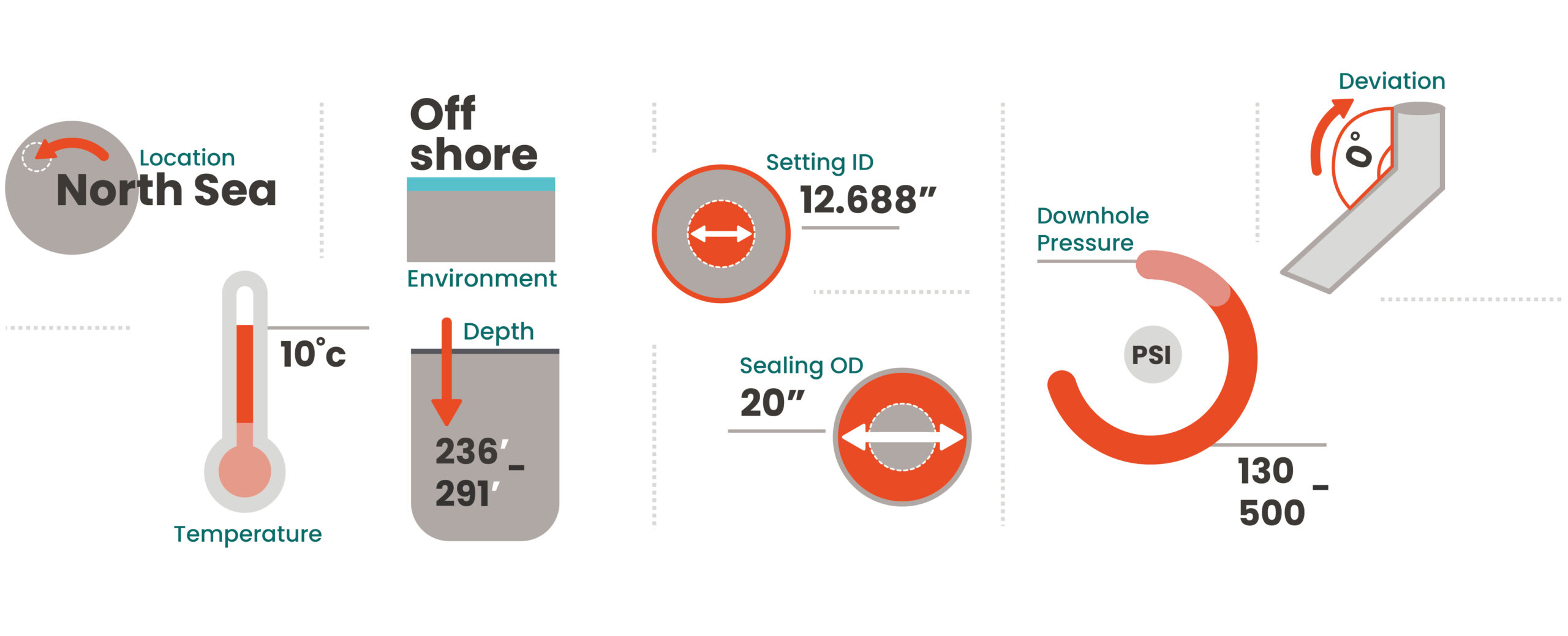

During a multi-well Plug & Abandonment campaign on a UK North Sea platform, the Operator encountered a previously unidentified shallow gas. This shallow gas was the result of super-charging of a non-hydrocarbon bearing sandstone close to the seabed as result of historical drilling operations.

The shallow gas resulted in continual gas-cut of the cement environmental barriers and leaks to surface. Remediation with traditional cement was difficult in such conditions due to the low temperatures.

The window for setting was limited given the length of barrier required to conform to wells being abandoned to full ‘AB2’ status as per industry and regulatory guidelines.

The operator identified that an alternative to cement was required to stem the flow of gas to surface, allowing for the wells to be abandoned to a safe condition. The drilling rig also needed to be relocated prior to the full decommissioning of the facility. BiSN were contacted to provide a bismuth-based alloy solution.

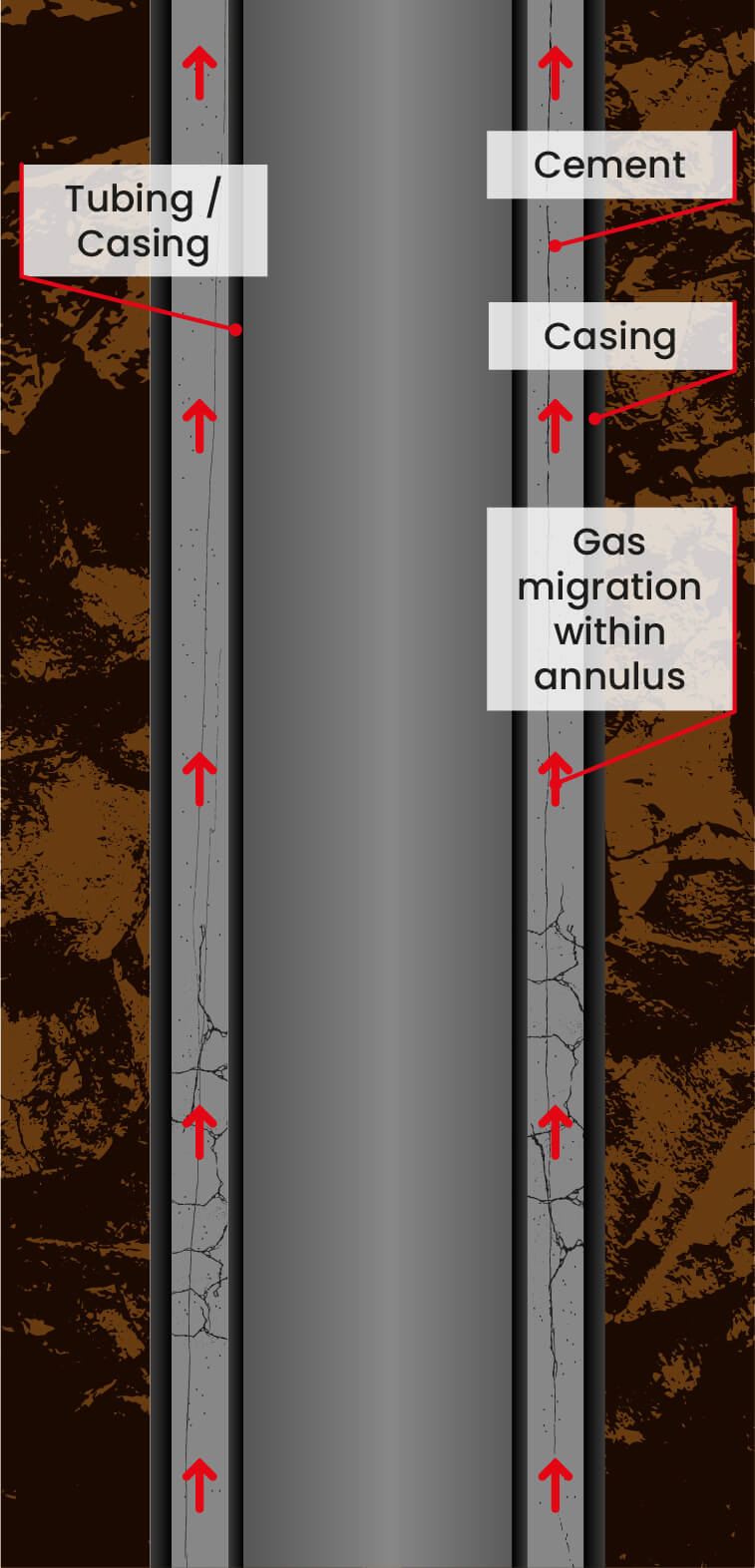

BiSN’s wel-lok™ technology has a proven track record of deployments in this application. Bismuth alloy forms an immediate impermeable barrier on solidification in the wellbore and instantly stops the flow of gas, preventing any gas-cut or percolation through the barrier material. Additionally, this technology dramatically shortens the section milled window allowing for environmental barriers to be installed with a very short window between the gas zone and the seabed. No other technology was deemed suitable to reliably create a gas tight barrier.

Initially, three wells were identified in the campaign, however after monitoring annulus pressures in another three wells, the decision was made to deploy wel-lok™ STC tools to ensure a gas-tight seal in six wells.

In total, seven wel-lok™ STC tools were deployed via Drill Pipe in six wells (five 13-3/8” x 20” barriers and one 9-5/8” x 13-3/8” barrier).

All plugs were successfully tested to 1,000psi and successfully inflow tested after setting. The six wells were continuously monitored for gas/pressure to surface over several weeks with zero bubbles reported.

With the use of BiSN’s wel-lok™ STC technology, all wells were now at ‘AB2’ abandonment status and the rig could leave location.

The previous use of cement as a P&A barrier against a shallow gas had led to significant over-run of the planned campaign and resulted in a delay of several months. BiSN wel-lok™ technology was able to be applied with reduced section milling and a shorter time frame.

The operator estimated that if BiSN’s wel-lok™ technology had been implemented from the beginning of the campaign, it could have saved them four months of rig time, resulting in up to $15m of savings.

The wel-lok™ STC (Seal Through Casing) has been developed to achieve a gas tight V0 seal well annuli that cannot be achieved by traditional cement balance plugs. Run on electric line, this tool does not need surface pumping equipment to circulate the alloy in place. Due to its viscosity and density, once melted the liquid alloy will flow with gravity into the annulus. When it cools below its melting point it solidifies, expands and creates a gas tight seal across the entire wellbore. The entire process, from melting to solidification, takes place in minutes and the seal is ready to test within an hour.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies