Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

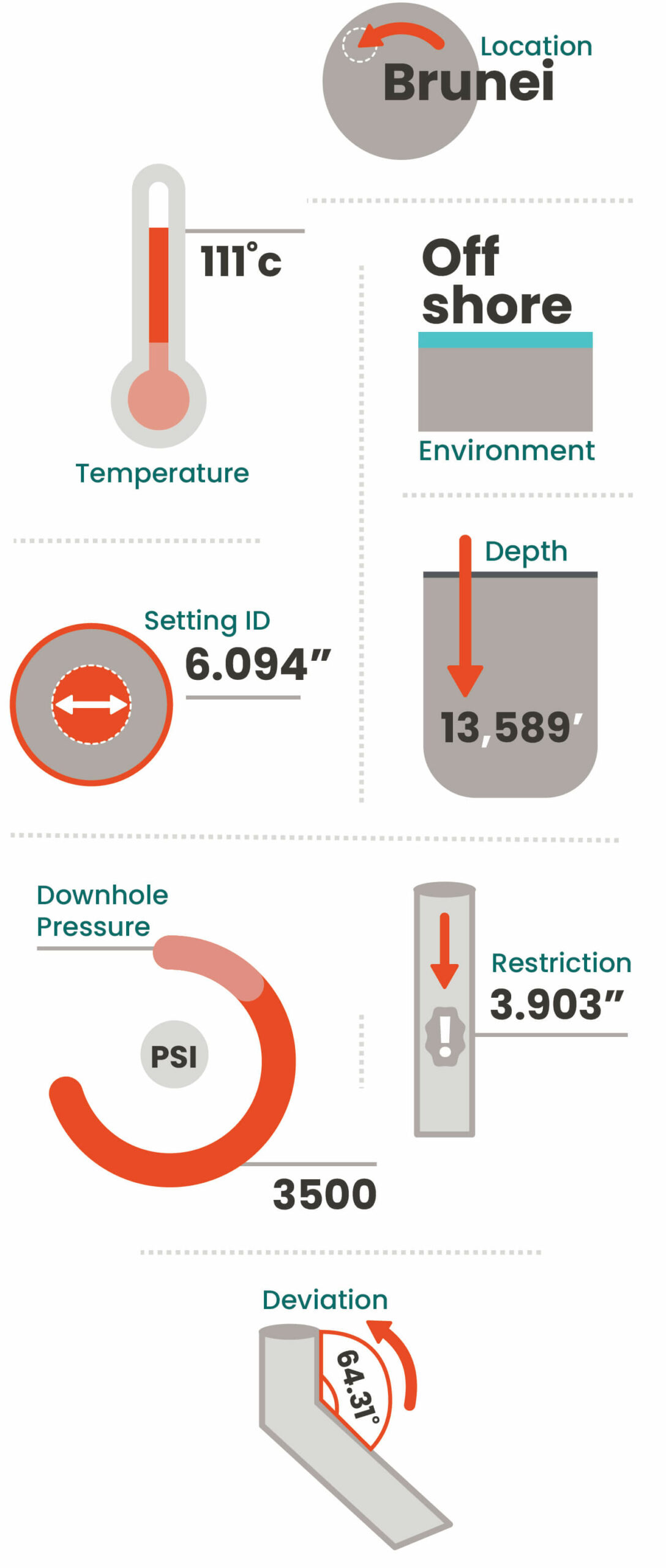

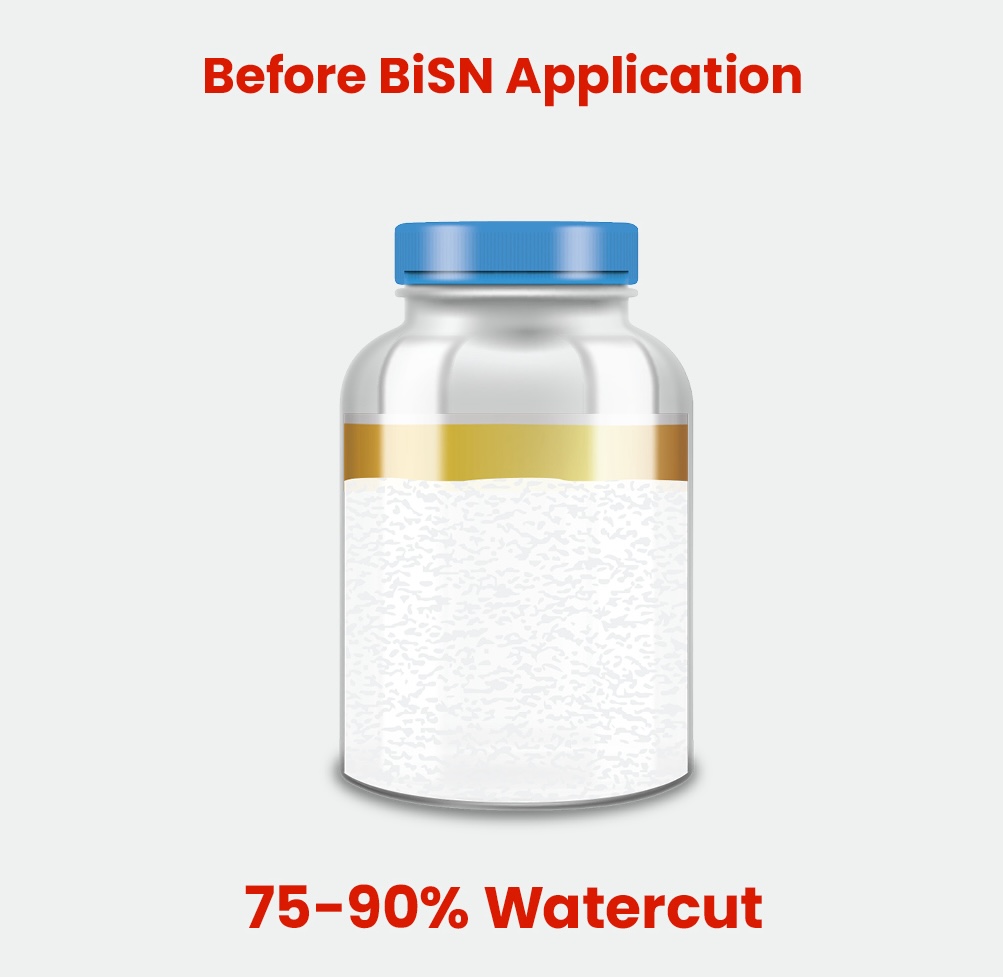

In Brunei, a challenge emerged for a supermajor operator faced with a well producing an overwhelming 75-90% water cut, significantly impeding the gas production rate. The necessity to navigate through 4.5″ tubing to achieve isolation within a 7″ production liner underscored the complexity of the task at hand.

The operation required a bespoke solution capable of traversing a 3.9″ restriction to effectively seal inside a 7″ perforated liner, aiming to mitigate the prevailing water production. The challenge was manifold: designing a tool with a 3.5″ diameter that could expand significantly to form an efficient barrier within the liner.

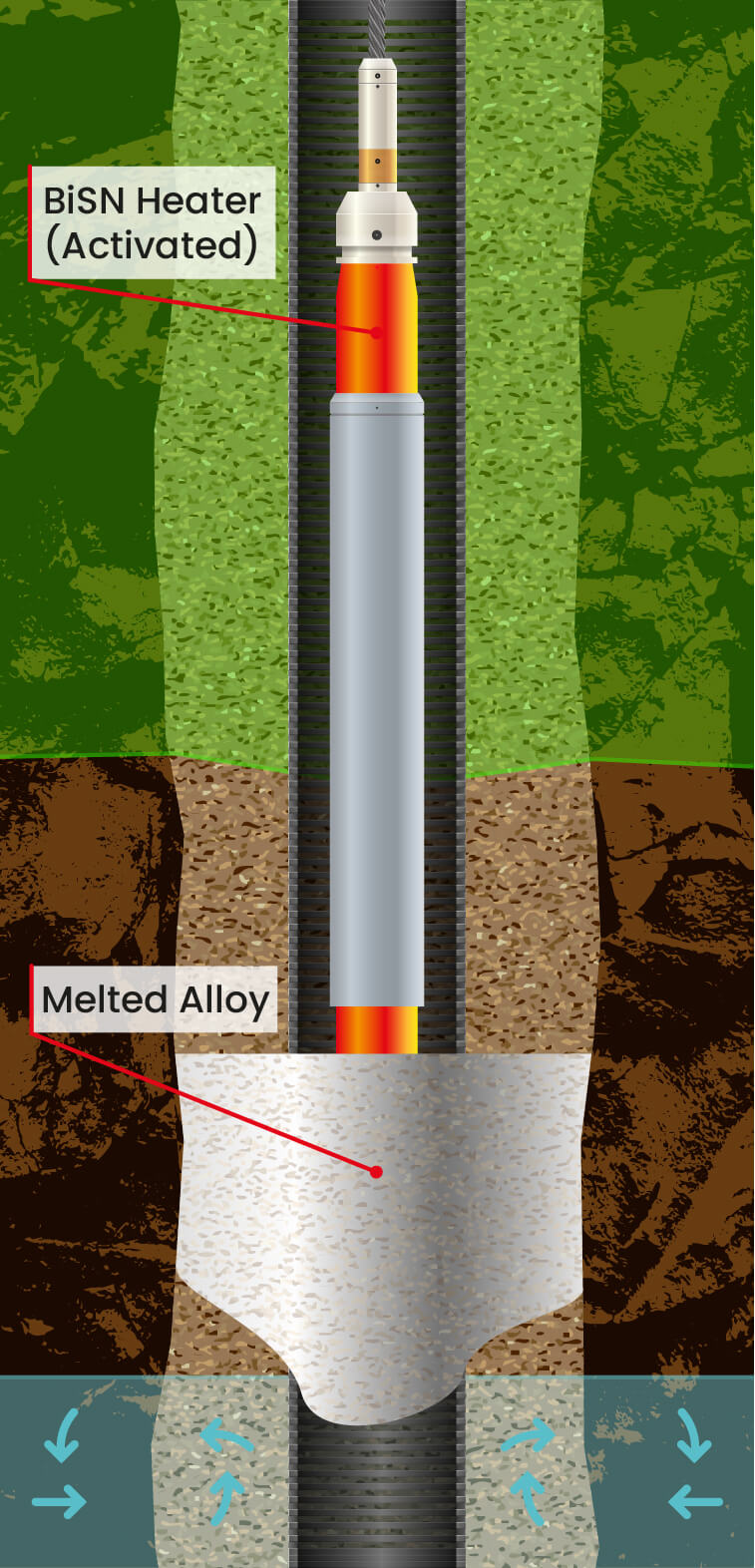

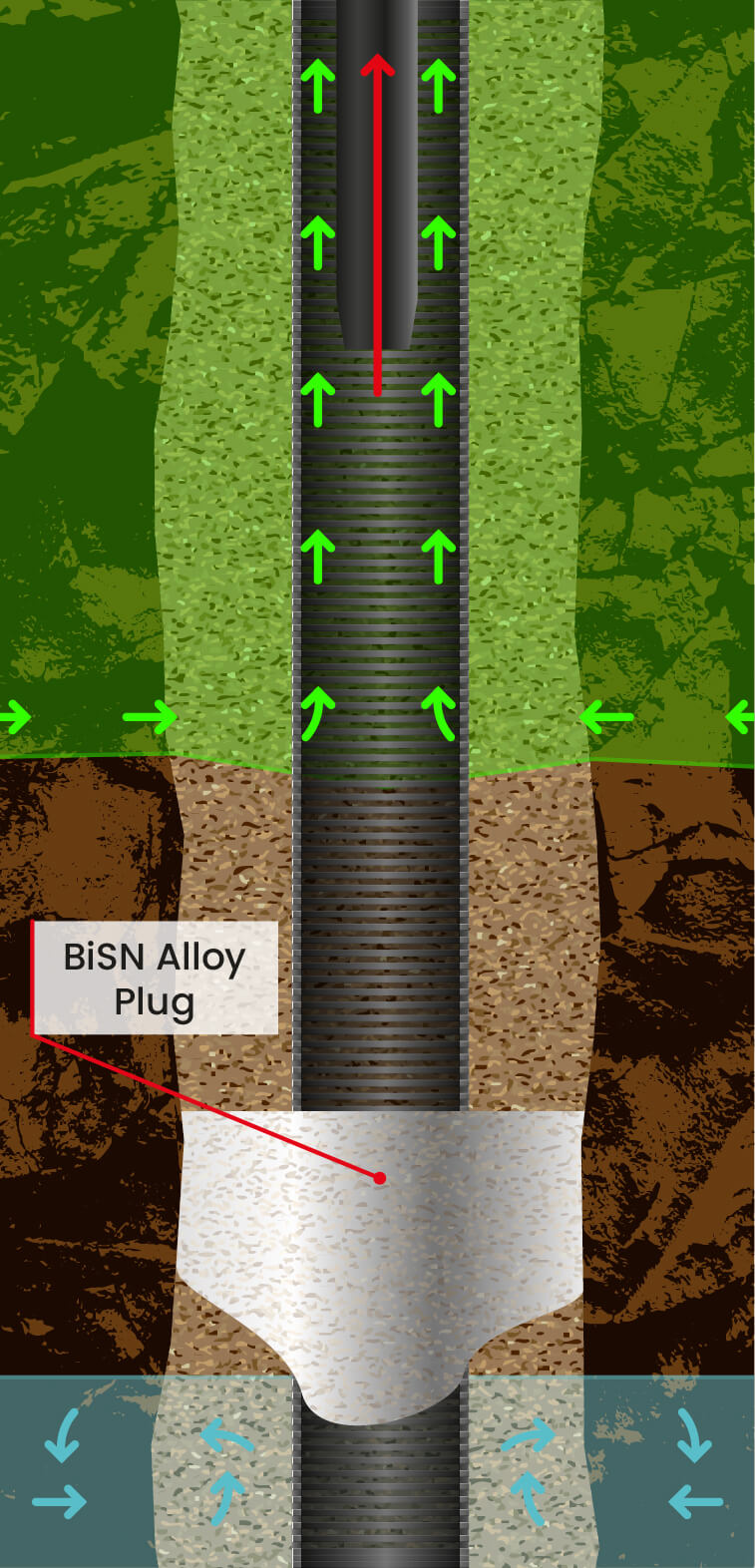

BiSN’s response was the deployment of the wel-lok™ WSO tool, engineered to pass through the tubing and reach the targeted isolation zone within the 7″ production liner. Activation of the chemical reaction heater initiated the melting process of the bismuth alloy. Characterized by its low viscosity, the liquid bismuth alloy flowed seamlessly, filling the gaps in the 7″ liner and perforations before solidifying. This process created a robust barrier, effectively halting water ingress.

The deployment of the WSO tool through the tubing marked a significant milestone, with the plug setting within the 7″ liner executed flawlessly. The intervention led to a dramatic reduction in water cut, from 75-90% down to 30-40%, thereby optimizing gas production and reducing the volume of wastewater requiring disposal.

BiSN’s intervention in Brunei stands as a testament to the efficacy of high-expansion water shut off solutions, delivering unparalleled results for the supermajor operator. This venture not only enhanced gas output but also contributed to substantial reductions in HSE risks, operational time, and costs. The successful execution in Brunei represents a pioneering achievement for BiSN, showcasing their capability to address and solve complex production challenges in the oil and gas sector.

The wel-lok™ WSO (Water Shut Off) has been specifically developed to reduce unwanted water production from wells with sand screen and open hole gravel pack completions (OHGP). Unlike any other solution on the market, the wel-lok™ WSO tool seals the annulus and the wellbore in one operation without the need to perforate the sandscreen or squeeze the alloy into the open hole annulus. The melted alloy fills inside the completion and in the annulus to form a metal to metal sealing solution that is seamless, significantly reducing unwanted water production.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies