Get in touch to find a permanent solution for your well

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Intervention with wel-lok™ PRT (Packer Repair Tool)

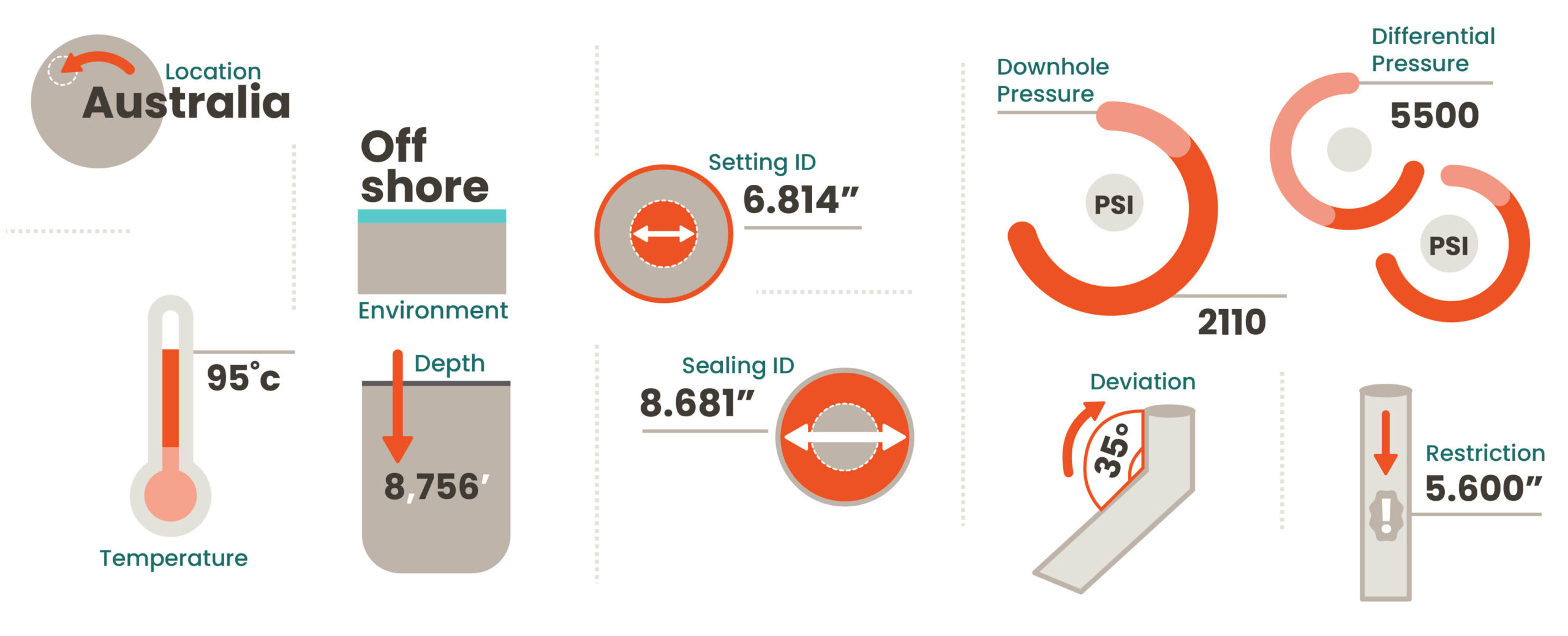

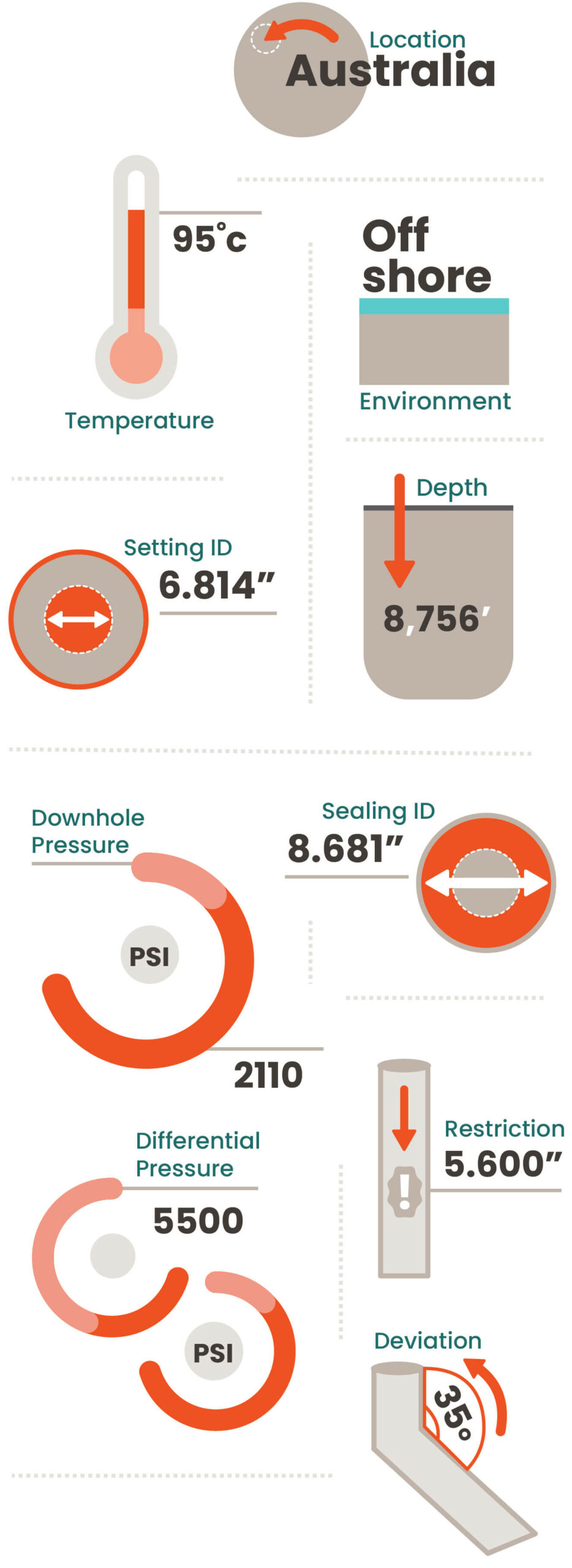

When a failure of the production packer caused the shut-in of a 2,800m deep offshore production well, the operator needed a safe and efficient solution to remediate the primary barrier between the reservoir and the annulus and to return the well to service as soon as possible.

With production targets to meet – and the excessive cost and time associated with deploying a conventional hydraulic workover unit (HWU) to contend with – the operator turned to BiSN for their innovative rigless wel-lok™ PRT (Packer Repair Tool) which creates a V0 qualified permanent barrier with bismuth based alloys in the annulus, something that cannot be achieved with existing traditional solutions. Our recommendation of a rigless intervention and reactivation wouldn’t just be a safer, more time-efficient and cost-effective solution – it would also be a world-first.

An HWU is a highly complex and expensive way to re-instate a well. In this case it would have taken in excess of 13 months to plan and 3 months of offshore execution to complete. Totalling $30million USD in unplanned costs to the operator.

BiSN’s proposed solution was categorized as new technology and hence had to be proved and qualified using a series of operator-witnessed systems integrity tests which simulated the exact wellbore conditions. This required design reviews and integration between several vendors to ensure the operation would go smoothly. Contingency plans and various means to deploy and position sealing technology above the failed packer, with no smaller ID restriction than originally installed in the completions, were investigated.

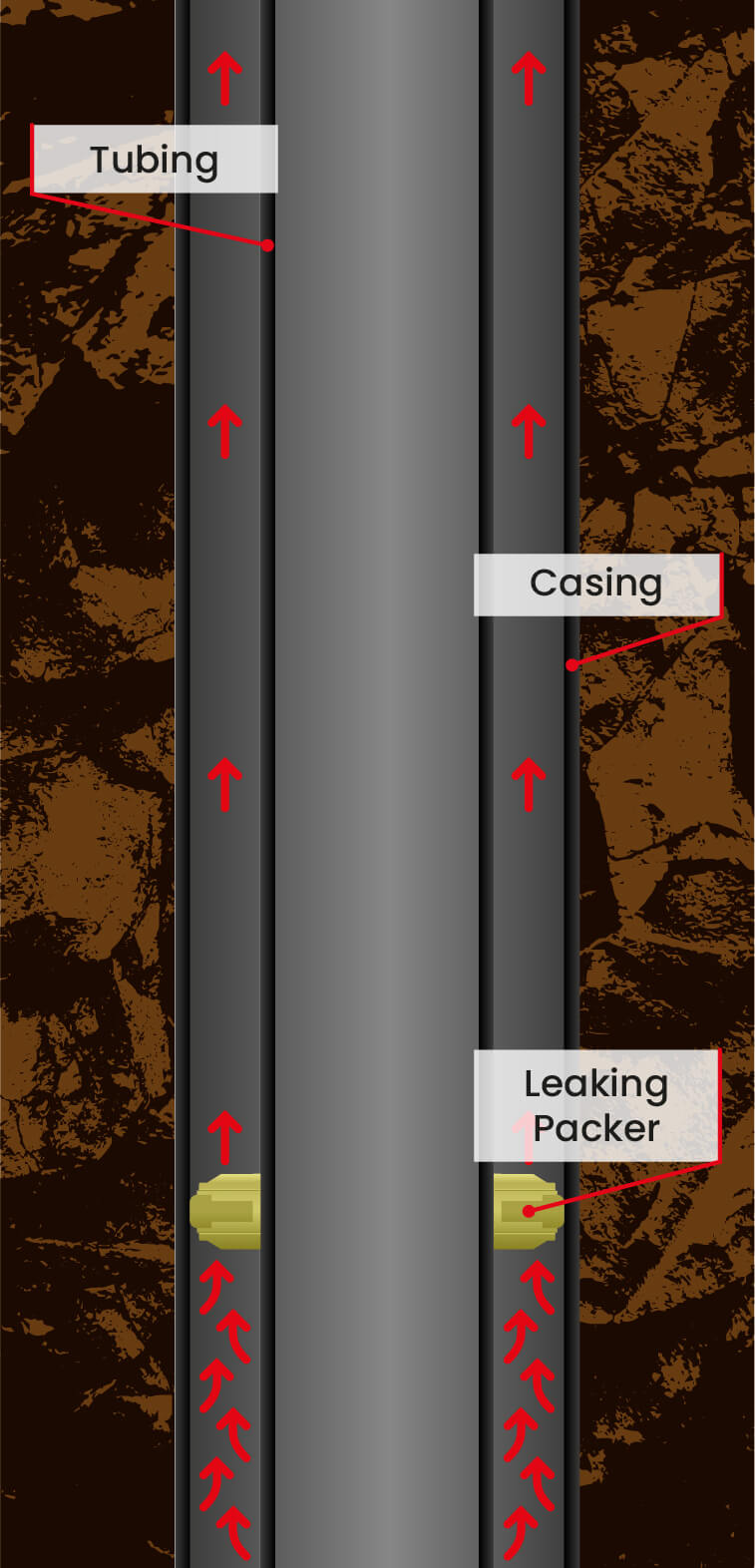

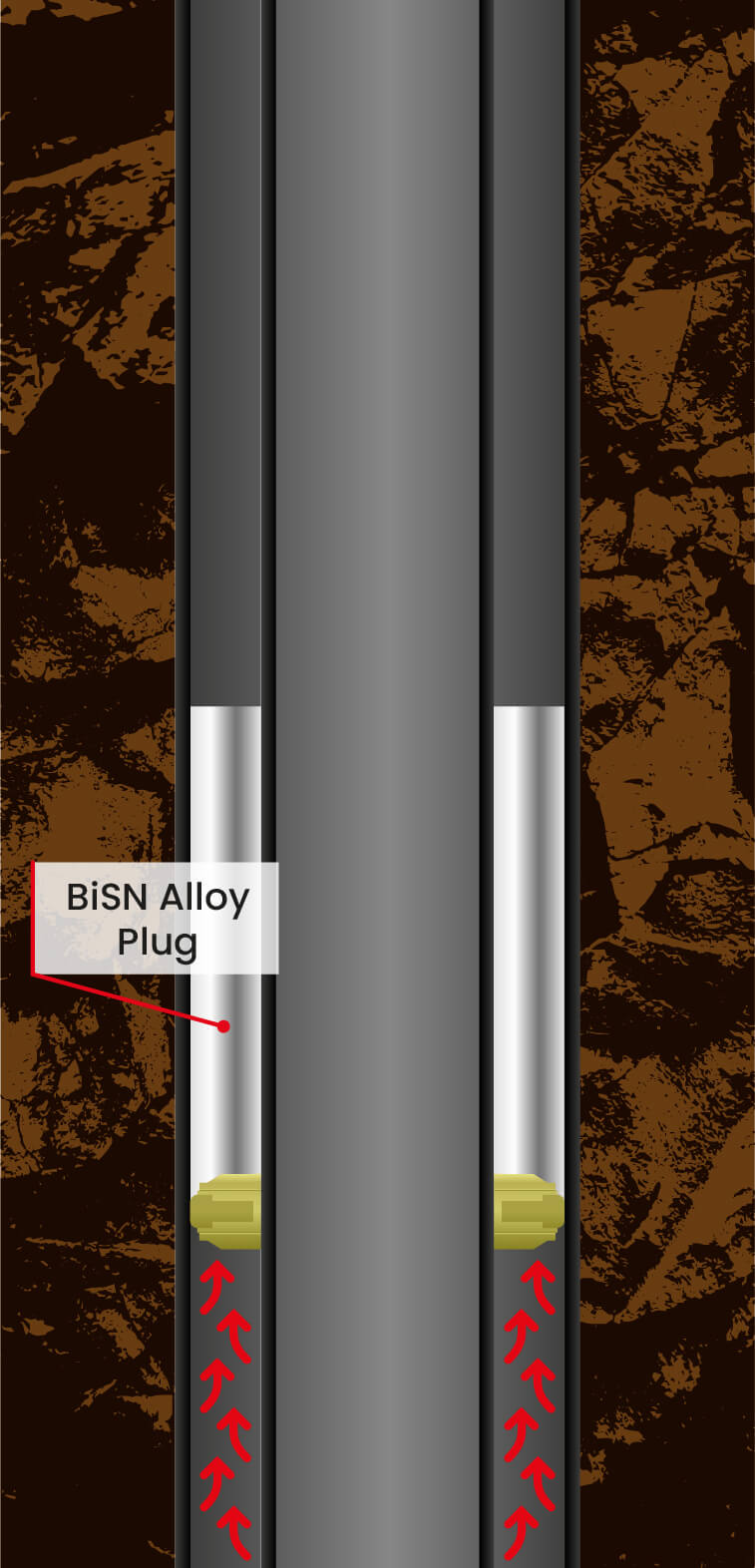

The proposed solution was to deploy the BiSN bismuth based alloy (sealing element) in the form of beads into the annulus to settle on top of the leaking packer. Once in place a BiSN heater would be run on wireline inside the tubing to the depth of the accumulated alloy beads and activated to melt the alloy and create a V0 seal in the annulus. The heater would then be retrieved allowing the well to be returned to service.

Because the alloy beads could not be deployed from surface due to restriction in the wellhead thorough testing was conducted to ensure that the alloy beads could be deployed through perforated holes at the desired deviation. Multiple systems integrity tests were conducted to qualify the plug and then further qualify it to V0 requirements specified by the operator. The complexity of new technology and first of its kind deployment meant alignment of various vendors to bring a suite of tools together for one successful operation.

The impact was game-changing for our operator. By utilizing this world-first downhole solution and leveraging the expertise of our dedicated well engineering specialists, we were able to reduce the cost of the intervention by over $30million USD and cut execution time by 66%. Shortening the project timeline from 18 months to 6 months by eliminating the need for a hydraulic workover unit.

By utilizing the new rigless technology, we were able to bring the well back online in an efficient and cost-effective way that minimized risk and managed the project from end-to-end – enabling the in-house team to focus on essential day-to-day operations.

Get in touch today to talk to our technical team.

The wel-lok™ PRT (Packer Repair Tool) is designed to repair a leaking production packer by creating a new seal in the production tubing by casing annulus. Sealing a production annulus with a PRT™ eliminates the need

to remove a production string from a well to replace the packer, reducing operator costs and downtime while introducing a superior seal in the well.

Businesses worldwide are benefitting from BiSN's well services in the field. Contact us today and embrace tomorrow's downhole well solution, today.

Our website uses analytics, marketing and preference cookies to both provide the most relevant experience for our users and to give us information about how our site is used. By clicking “Accept All”, you consent to the use of these cookies. However, you may visit "Cookie Settings" to provide a controlled consent.

Accept All Cookies